2025 Top HMI Control Panel Trends and Innovations You Need to Know

As we move toward 2025, the landscape of Human-Machine Interface (HMI) control panels is poised for significant evolution, driven by advancements in technology and changing industry demands. According to a recent report published by MarketsandMarkets, the HMI market is projected to grow from USD 4.6 billion in 2020 to USD 7.0 billion by 2025, reflecting a CAGR of 8.6%. This acceleration highlights the increasing reliance on HMI control panels across various sectors, including manufacturing, energy, and transportation, as organizations seek to enhance operational efficiency and user experience.

Innovations in HMI control panels are not only about improving functionality but also regarding the integration of cutting-edge technologies like IoT, AI, and advanced visualization techniques. As businesses strive for greater automation and real-time data access, the demand for intuitive and responsive HMI systems is more critical than ever. A significant trend is the shift towards touchless interfaces and voice recognition technologies, which are enhancing user interaction while ensuring safety and productivity.

Furthermore, with the growing emphasis on sustainability and smart manufacturing, HMI control panels are evolving to provide more data-driven insights and energy management capabilities. By leveraging these innovations, industries can optimize processes, improve safety, and respond more agilely to market changes, making the study of 2025 HMI control panel trends and innovations essential for any organization aiming to stay competitive.

Emerging Technologies Shaping HMI Control Panels by 2025

As we approach 2025, the landscape of Human-Machine Interface (HMI) control panels is undergoing a significant transformation driven by emerging technologies. One of the key innovations shaping this evolution is the integration of artificial intelligence (AI) and machine learning algorithms into HMI systems. These technologies enable predictive maintenance, which allows operators to anticipate equipment failures before they occur. This proactive approach not only minimizes downtime but also enhances operational efficiency, helping industries to optimize their resources.

In addition to AI, advancements in touchless control technology are poised to redefine user interactions with HMI panels. Gesture recognition and voice command systems are becoming increasingly sophisticated, allowing operators to control machinery and monitor processes without physical contact. This shift promotes a safer and more hygienic working environment, particularly crucial in industries where cleanliness is paramount. Moreover, these innovations are supported by advancements in sensor technology, which further enhances the responsiveness and accuracy of control panels.

Lastly, the rise of augmented reality (AR) and virtual reality (VR) presents new opportunities for HMI systems. These immersive technologies enable operators to visualize complex data and simulations in a three-dimensional space, facilitating better decision-making and training processes. By bridging the gap between the digital and physical worlds, AR and VR enhance the user experience, making control panels more intuitive and interactive. As these technologies continue to develop, the HMI control panel of 2025 promises to be more intelligent, user-friendly, and seamlessly integrated into industrial operations.

2025 HMI Control Panel Trends and Innovations

This chart illustrates the anticipated adoption rates of various trends shaping HMI control panels by 2025. The trends include AI integration, touchless interfaces, augmented reality applications, edge computing solutions, and increasing customization options. As industries continue to evolve, these innovations are expected to enhance usability and efficiency in HMI systems.

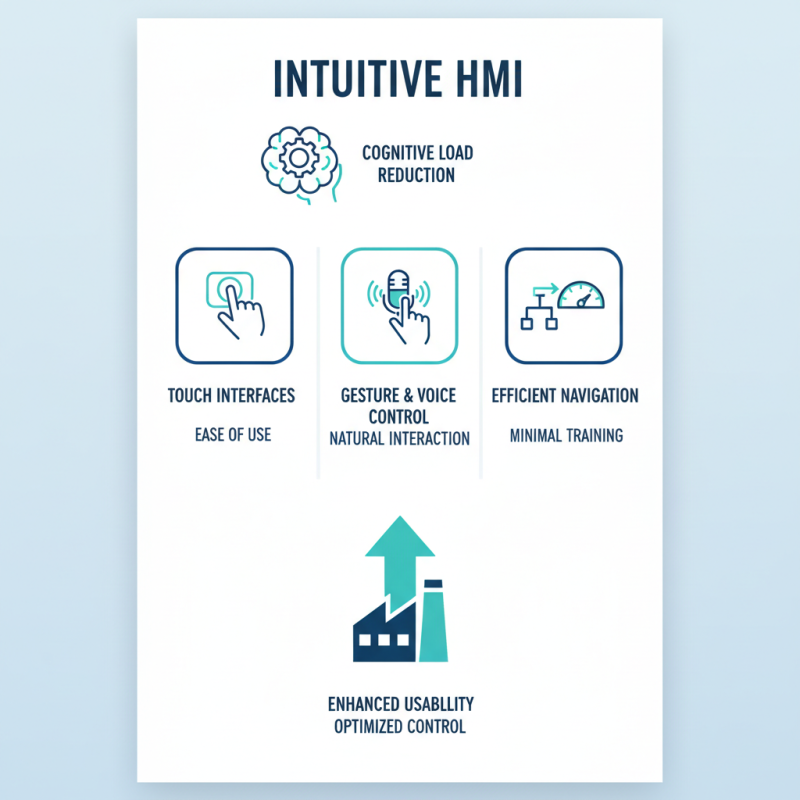

Intuitive User Interfaces: Enhancing Interaction in Control Panels

In recent years, the focus on intuitive user interfaces in Human-Machine Interface (HMI) control panels has significantly reshaped how operators interact with complex systems. These user interface innovations prioritize ease of use, ensuring that operators can efficiently navigate and control processes with minimal training. The integration of touchscreens, gesture controls, and voice recognition technologies has made it possible for users to engage with control panels in a more natural and seamless manner. These advancements not only enhance usability but also reduce the cognitive load on operators, allowing them to focus on critical tasks rather than struggling with cumbersome navigation.

Moreover, the design of control panels has evolved to support customizable interfaces that cater to individual operator preferences and workflows. This personalization enhances user engagement and satisfaction, as operators can set up their dashboards to display the most relevant data and controls for their specific needs. Additionally, the incorporation of real-time data visualization and analytics tools empowers users to make informed decisions quickly, further streamlining operations. In this way, the trend toward intuitive user interfaces is not just about aesthetics; it fundamentally transforms how operators interact with technology, promoting efficiency and safety in various industries.

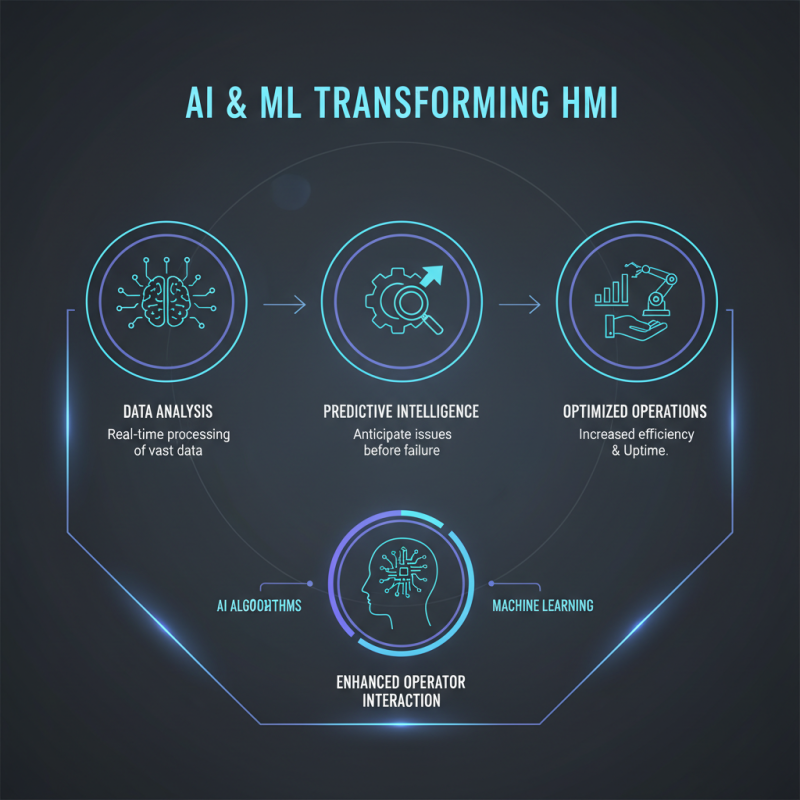

Integration of AI and Machine Learning in HMI Systems

The integration of artificial intelligence (AI) and machine learning into Human-Machine Interface (HMI) systems is transforming the way operators interact with machinery and technology. By leveraging AI algorithms, HMI systems can analyze vast amounts of data in real time, enabling predictive maintenance and automated problem detection. This evolution not only enhances operational efficiency but also minimizes downtime, as potential issues can be identified and addressed before they escalate into critical failures.

Moreover, the use of machine learning facilitates intuitive user experiences by personalizing interfaces based on individual operator behaviors and preferences. This adaptability allows for greater ease of use, which is especially beneficial in complex industrial environments where operators may be required to manage multiple tasks simultaneously. As HMI systems become more intelligent, they can provide tailored insights, streamline workflows, and even suggest optimal operating conditions, ultimately aiding businesses in achieving higher productivity and safety standards.

Advancements in Touchscreen and Gesture Control Technologies

The landscape of Human-Machine Interface (HMI) control panels is rapidly evolving, driven by advancements in touchscreen and gesture control technologies. Touchscreens are becoming increasingly sophisticated, featuring higher resolutions and improved sensitivity that enable a more intuitive user experience. With the integration of haptic feedback, users can now receive tactile responses from the display, enhancing interactivity and making the operation of control panels more engaging. This level of responsiveness is crucial in applications where precise control is necessary, such as in industrial automation and complex machinery.

Gesture control technologies are also emerging as a key trend in HMI design. By allowing users to interact with devices through natural gestures, this technology minimizes the need for physical touch, thereby reducing wear on devices and promoting hygiene in environments where cleanliness is paramount. Advanced algorithms and sensors are being developed to accurately detect and interpret user gestures, enabling seamless control over various functions. This innovation not only simplifies user interactions but also opens possibilities for hands-free control in environments where manual input may be impractical or unsafe. As these technologies continue to advance, they will redefine the way operators engage with machines, offering more flexibility and efficiency in various industries.

Sustainability and Energy Efficiency Trends in HMI Design

As industries move towards a more eco-conscious future, the integration of sustainability and energy efficiency in Human-Machine Interface (HMI) design has gained significant traction. Designers are increasingly focused on creating interfaces that not only enhance user experience but also minimize energy consumption. This alignment with sustainable practices entails using energy-efficient components, such as low-power displays and optimized software algorithms that reduce processing demands. By lowering the operational footprint of HMI systems, manufacturers can play a pivotal role in advancing eco-friendly initiatives within their facilities.

Another emerging trend is the incorporation of environmentally responsible materials in HMI control panel production. The use of recycled plastics, biodegradable materials, and sustainable coatings not only reduces waste but also supports the lifecycle management of electronic systems. Moreover, the capability to monitor energy usage in real-time through sophisticated HMI designs enables operators to make informed decisions that lead to further energy savings. As these innovations continue to evolve, the commitment to sustainability will undoubtedly become a defining characteristic of the HMI sector, fostering a more responsible manufacturing ethos that aligns with contemporary environmental standards.

2025 Top HMI Control Panel Trends and Innovations You Need to Know

| Trend/Innovation | Description | Impact on Sustainability | Energy Efficiency Benefits |

|---|---|---|---|

| Smart HMI Interfaces | Use of advanced artificial intelligence to enhance user interaction. | Reduces waste by optimizing resource use. | Minimizes energy consumption through predictive analytics. |

| Sustainable Materials | Integration of eco-friendly materials in HMI design. | Lowers environmental impact in manufacturing. | Enhances lifecycle efficiency of HMI products. |

| Cloud-Based Systems | Leveraging cloud technology for improved data sharing. | Allows real-time monitoring and reduced waste. | Enables optimization of energy use across systems. |

| Modular HMI Design | Flexible components that can be updated or replaced easily. | Promotes longevity and reduces resource depletion. | Improves energy management through modular control. |

| User-Centric Design | Focus on enhancing user experience and safety. | Encourages responsible use of energy and resources. | Reduces errors leading to lower energy waste. |

Related Posts

-

How to Optimize Your HMI Control Panel for Enhanced User Experience

-

The Rise of Control Cubicles in Modern Workspaces Enhancing Productivity and Employee Satisfaction

-

How to Create Efficient Electrical Control Panel Designs for Optimal Performance

-

How to Master Electrical Control Panel Design for Your Next Project

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency

-

7 Best Electrical Power Distribution Panel Features to Maximize Efficiency in Your Facility