2026 Top Trends in HMI Programming for Innovative Automation Solutions?

In recent years, HMI programming has gained significant attention in the realm of automation. The evolving landscape demands innovative solutions that enhance user experience and operational efficiency. As we look forward to 2026, several trends are reshaping this field. These trends focus on making interfaces more intuitive and adaptable.

Developers are now prioritizing user-centric design. This shift aims to simplify complex processes. Enhanced machine learning capabilities will also play a crucial role. They help systems learn and respond faster to user inputs. Yet, there are challenges. Integration of new technologies can be daunting for many teams. Not all systems will easily adapt to these changes.

Investing in HMI programming may require reevaluating existing practices. Organizations must commit to ongoing training. Without proper support, even the best innovations may falter. The future holds great potential, but it demands careful planning and execution. Embracing change is vital for success in this dynamic field.

The Rise of AI and Machine Learning in HMI Programming for Automation

The integration of AI and machine learning into HMI programming is transforming automation landscapes. These technologies are enabling systems to analyze vast amounts of data in real-time. For instance, predictive analytics can foresee equipment failures before they occur, reducing downtime. This shift enhances operational efficiency and significantly boosts productivity.

However, there are challenges to consider. Implementing these advanced technologies often requires specialized skills. Many teams may struggle with the steep learning curve associated with AI and machine learning. Additionally, reliance on algorithms can lead to unforeseen errors. If systems are not properly trained, they may produce inaccurate results. Balancing innovation with reliability remains a crucial concern.

Moreover, ethical implications arise as automation grows. Ensuring data privacy and security is paramount. Organizations need to establish guidelines for responsible AI use in HMI programming. As automation evolves, there remains a need to understand the human element. Technology should complement human skills, not replace them. This delicate balance will define the future of innovative automation solutions.

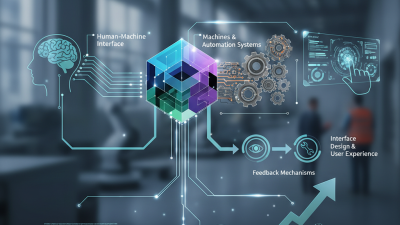

Key Innovations in User Interface Design for Enhanced HMI Usability

In recent years, user interface design has evolved significantly, impacting Human-Machine Interface (HMI) programming. According to a report from MarketsandMarkets, the global HMI market is projected to reach $6.5 billion by 2026. This growth highlights the increasing importance of innovative UI design. Effective design enhances usability, making automation systems more accessible to operators.

Simple navigation and intuitive layouts become essential.

Additionally, color schemes and visual hierarchies are vital. A study from Nielsen Norman Group found that users can retain up to 80% of the information presented visually. By prioritizing clear visuals, developers can create systems that reduce cognitive load. Yet, achieving this balance is challenging. Some interfaces still overwhelm users with complex designs or confusing icons. It’s crucial for designers to regularly test and refine their interfaces based on real user feedback.

Moreover, the integration of touch and gesture control has changed interaction dynamics. Research indicates a 30% increase in efficiency when adopting these methods. However, not all users are comfortable with these technologies. Variability in user skill levels can lead to frustration. Designers must remain aware of this diversity and strive for solutions that accommodate beginners and experts alike. Continuous improvement in HMI programming relies on addressing these usability gaps.

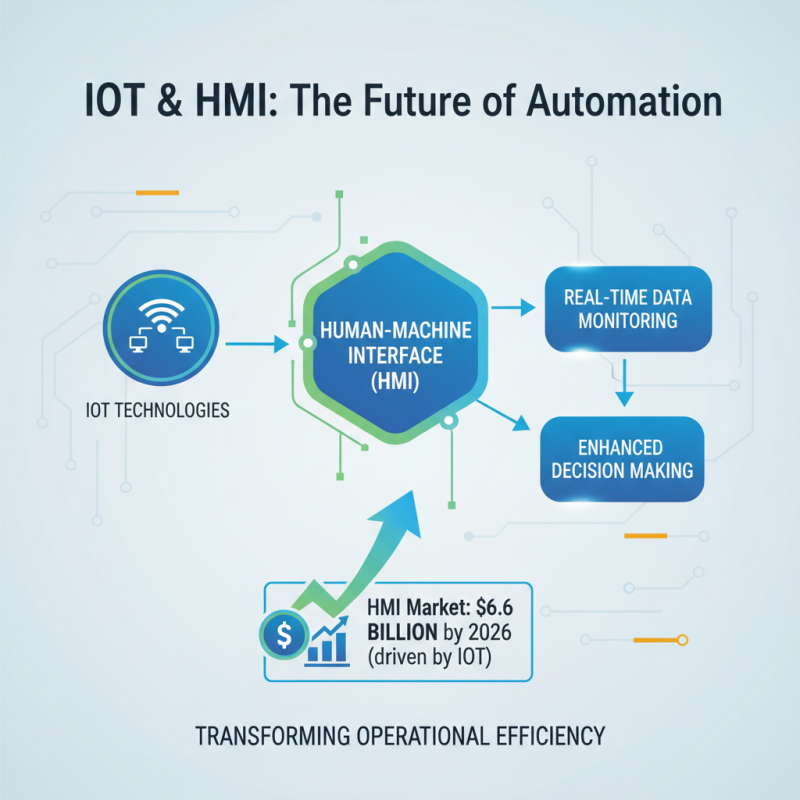

Integration of IoT Technologies for Real-Time Data Monitoring in HMI Systems

The integration of IoT technologies into Human-Machine Interface (HMI) systems is transforming automation. Real-time data monitoring is a critical component. According to a report by MarketsandMarkets, the HMI market is expected to reach $6.6 billion by 2026, driven largely by IoT integration. This trend will enhance operational efficiency and decision-making processes.

However, challenges persist. Not all industries are ready for such rapid advancements. Some organizations struggle with outdated infrastructure. This can hinder the seamless flow of real-time data. In fact, a survey by Allied Market Research indicated that nearly 40% of manufacturers still rely on legacy systems. This creates a gap between potential benefits and actual implementation.

Moreover, as more data is generated, ensuring data security becomes paramount. The complexity of integrating IoT devices with HMI systems raises concerns. Cybersecurity threats are increasingly prevalent. Organizations must address vulnerabilities to fully harness the advantages of real-time monitoring. Balancing innovation and security will be key for future growth in HMI programming.

Trends in Mobile HMI Solutions for Increased Flexibility in Automation

The rise of mobile HMI solutions is transforming automation. According to a recent market analysis, the mobile HMI market is projected to grow by 10% annually over the next five years. This growth indicates a shift towards increased flexibility and user accessibility in automation processes. Mobile HMIs enable operators to interact with machines from anywhere. This flexibility can optimize workflows significantly.

However, the implementation of mobile HMIs comes with challenges. Data security is a major concern. With devices connected remotely, protecting sensitive information is critical. Additionally, training staff to utilize mobile HMI systems effectively remains essential yet often overlooked. Industry reports highlight that 40% of companies struggle with this aspect, leading to inefficiencies.

Integration of mobile HMIs into existing systems can also present difficulties. Often, companies face compatibility issues with legacy systems. Addressing these issues requires careful planning and skilled personnel. Continuous feedback from users is necessary to refine these systems. The journey towards fully functional mobile HMI solutions is ongoing, full of learning opportunities and areas for improvement.

Impact of Cybersecurity Measures on HMI System Development and Reliability

In the evolving landscape of HMI programming, cybersecurity has emerged as a focal point. According to a recent report by Cybersecurity Ventures, cybercrime damages are projected to reach $10.5 trillion annually by 2025. This staggering figure underlines the urgency for robust security measures in HMI systems.

Incorporating advanced cybersecurity protocols can significantly enhance system reliability. Research shows that 75% of industrial automation companies faced cyber incidents in past years. This highlights an alarming trend that demands immediate attention. Despite increased investment in cybersecurity, many systems still lack adequate protection. A survey indicated that 30% of HMI developers continue to neglect security during the design phase.

Furthermore, the integration of cybersecurity features is often seen as a secondary consideration. Developers often prioritize functionality over security. The result? Vulnerable systems that can lead to disastrous breaches. With the evolving threats in industrial environments, it's clear that a shift in mindset is essential. Organizations must adopt a comprehensive approach to security in HMI programming if they want to stay ahead of cyber threats.

Related Posts

-

What is HMI Programming and How to Get Started with It

-

10 Essential Tips for Designing an Efficient Electrical Control Panel

-

Top 5 Essential Control Panel Drawings You Need for Your Projects

-

How to Optimize Control Systems for Improved Efficiency and Performance

-

Top 10 Benefits of Using PLC Control in Industrial Automation Solutions

-

Understanding PLC Control Panels: Essential Components and Their Impact on Automation Efficiency