Top 10 Benefits of Using PLC Control in Industrial Automation Solutions

In the realm of industrial automation, the adoption of PLC control systems has revolutionized operations across various sectors. According to Dr. John Matthews, a leading expert in automation technology, "The integration of PLC control not only enhances efficiency but also significantly reduces downtime, paving the way for smarter manufacturing processes." This statement underscores the transformative impact that programmable logic controllers have on industry standards and practices.

As manufacturers strive for higher productivity and interoperability, the benefits of PLC control become increasingly apparent. From improved process management to enhanced safety protocols, organizations are recognizing that implementing PLC systems can lead to substantial gains in performance and reliability. In a rapidly evolving industrial landscape, the demand for adaptable and scalable automation solutions is paramount, and PLC control stands at the forefront of these advancements.

The upcoming discussion will delve into the top 10 benefits of utilizing PLC control in industrial automation solutions, providing insights into how these systems can help organizations maintain competitive advantages in the market. By exploring the potential of PLC control, companies can better understand its role in shaping the future of industrial automation.

Understanding PLC Control: The Backbone of Industrial Automation

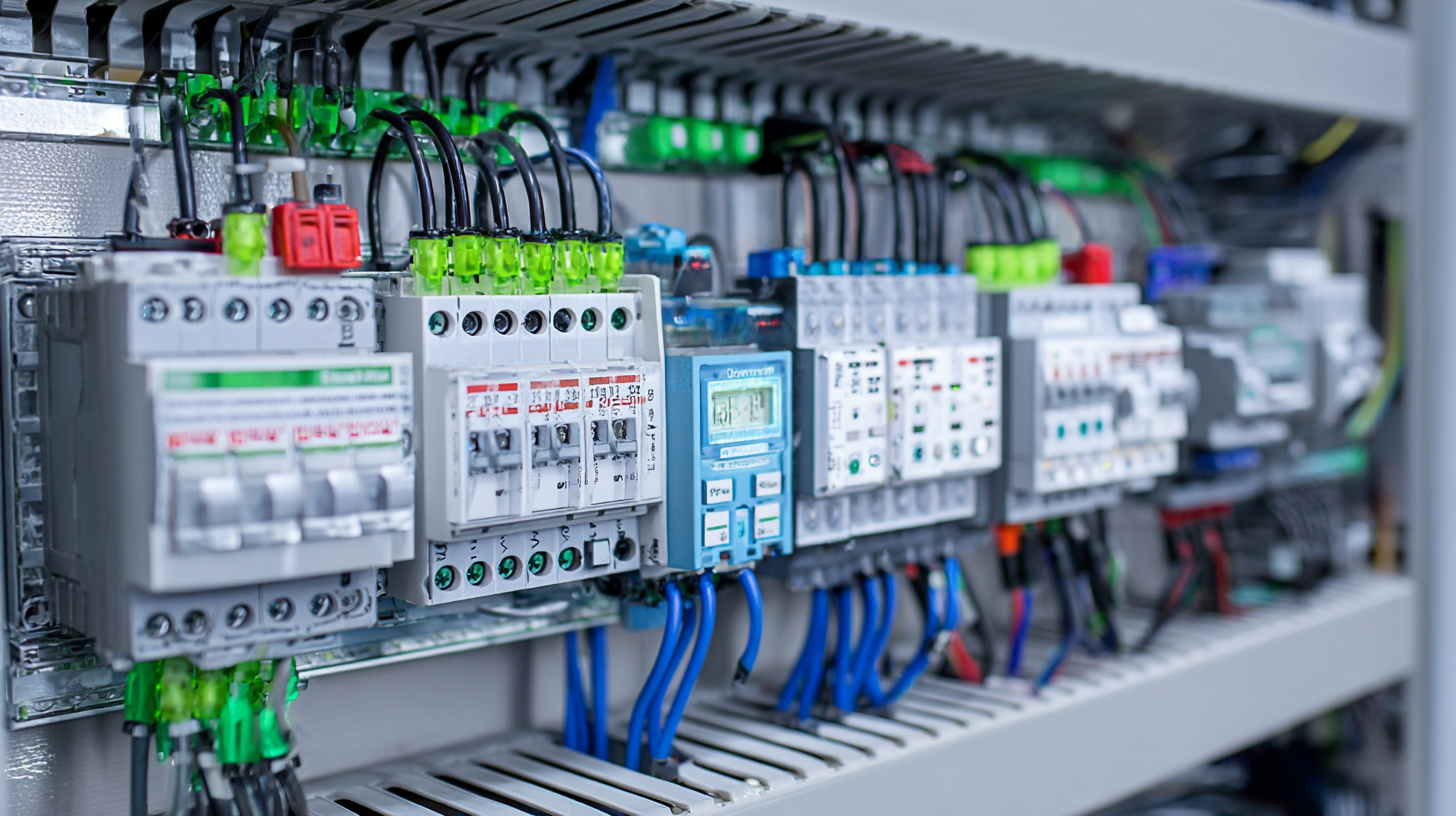

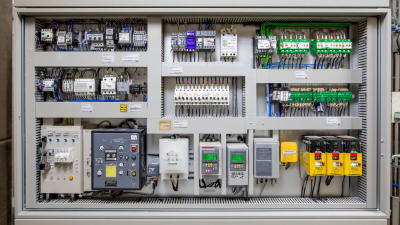

Programmable Logic Controllers (PLCs) are integral to modern industrial automation, serving as the backbone that supports intricate operations in manufacturing environments. These devices enhance the efficiency and reliability of processes by allowing for programmable control of machinery and systems. Unlike traditional relay-based control systems, PLCs offer flexibility and ease of reprogramming, which is crucial for adapting to changing production requirements and technologies.

The use of PLCs results in substantial improvements in operational productivity and safety. They facilitate real-time monitoring and control, enabling prompt responses to operational anomalies or equipment failures. Moreover, PLCs are designed to withstand harsh industrial conditions, showcasing durability and long service life. This reliability not only reduces maintenance costs but also minimizes downtime, ultimately contributing to a more streamlined and efficient production process.

By harnessing PLC technology, industries can achieve greater control, optimize performance, and drive continuous improvement in automation solutions.

Enhancing Operational Efficiency Through PLC Integration

Programmable Logic Controllers (PLCs) have revolutionized industrial automation by significantly enhancing operational efficiency. By integrating PLC systems, industries can streamline processes, reduce manual intervention, and enable real-time monitoring. This automation not only minimizes human error but also ensures a faster response to machinery and system failures, ultimately boosting productivity. Moreover, the scalability of PLCs allows for easy adaptation to changes in production demands, making them a vital component in modern factories.

Tip: To maximize the benefits of PLC integration, ensure your team receives comprehensive training on the system’s functionalities. This knowledge empowers operators to utilize the PLC to its full potential and troubleshoot minor issues independently, reducing downtime.

In addition to efficiency, PLCs facilitate improved data collection and analysis. By providing accurate metrics and performance insights, organizations can identify bottlenecks and optimize their workflows. This data-driven approach leads to informed decision-making, enabling continuous improvements in productivity and quality.

Tip: Regularly review your PLC system's performance data to identify trends and areas for improvement. Implementing minor adjustments based on this analysis can yield substantial enhancements in overall operational efficiency.

Cost-Effectiveness of PLC Control in Manufacturing Processes

The cost-effectiveness of PLC (Programmable Logic Controller) control in manufacturing processes is a compelling advantage that significantly enhances operational efficiency. By automating complex tasks and minimizing manual intervention, PLC systems reduce labor costs and the likelihood of human errors, which can lead to costly downtime. The initial investment in PLC technology often translates to long-term savings through improved production rates and lower operational costs. Furthermore, PLCs are designed for flexibility, allowing manufacturers to easily adapt their systems without extensive reconfiguration, which can save both time and resources.

In addition to direct financial benefits, PLC control contributes to the optimal use of materials and energy within manufacturing processes. By providing precise control over machinery and processes, PLCs ensure that resources are utilized efficiently and waste is minimized. This not only helps in reducing costs but also supports sustainability initiatives by decreasing the environmental footprint of manufacturing operations. Overall, the implementation of PLC systems represents a strategic investment that enhances profitability while fostering an agile manufacturing environment.

Top 10 Benefits of Using PLC Control in Industrial Automation Solutions

Boosting System Reliability and Safety with PLC Automation

Programmable Logic Controllers (PLCs) have revolutionized industrial automation by enhancing both system reliability and safety. With the ability to execute complex control functions with precision, PLCs minimize human error, a significant contributor to workplace accidents. According to a report by the International Society of Automation, companies that implemented PLC systems saw a 30% reduction in equipment failures and a notable decrease in downtime, illustrating the substantial impact of automation on operational efficiency.

Moreover, PLCs contribute to safety by providing real-time monitoring and control of machinery. This functionality allows for immediate responses to abnormal conditions, helping prevent accidents before they occur. The U.S. Bureau of Labor Statistics stated that industries utilizing PLC-controlled systems reported a 25% drop in workplace injuries over a five-year span. These statistics highlight the importance of integrating PLCs into industrial processes to safeguard both employees and assets.

Tip: When upgrading to PLC automation, ensure that your staff is well-trained to use these systems effectively. Investing in training can enhance both productivity and safety, leading to a more resilient operation. Additionally, regular maintenance of PLC systems can prevent potential failures and improve overall system reliability.

Improved Flexibility and Scalability in Industrial Operations

The advent of PLC (Programmable Logic Controller) control systems in industrial automation has significantly improved flexibility and scalability in operations. As industries increasingly embrace Industry 4.0 technologies, the integration of virtual and soft PLCs has become vital. These advanced systems allow manufacturers to modify processes swiftly in response to changing production demands, enhancing the adaptability of operations in dynamic market environments.

Furthermore, the move towards cloud and on-premise deployments of automation solutions facilitates seamless communication between different production units. This enables real-time data analytics and better decision-making, which are crucial for optimizing operational efficiency. The scalability offered by PLC technology allows businesses to expand their automation capabilities without the need for significant overhauls. As such, organizations can quickly scale their processes up or down based on demand, ensuring they remain competitive and responsive to customer needs.

Related Posts

-

Enhancing Industrial Efficiency: The Future of PLC Control Systems in Smart Manufacturing

-

Revolutionizing Industries with Next Generation Automation Control Panels

-

How to Master PLC Controller Programming for Industrial Automation

-

What is the Importance of PLC Programming in Modern Automation

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

What Are Electrical Control Solutions and How Do They Revolutionize Automation?