Top 10 Benefits of Using PLC Control Panels for Automation Systems

In the rapidly evolving landscape of industrial automation, the integration of PLC control panels has become a game-changer. A recent report by the International Society of Automation highlights that companies using PLCs have seen a 30% increase in efficiency. This remarkable statistic emphasizes the value of PLC control panels in modern systems. Industry expert Dr. James Hartwell states, "The versatility and reliability of PLC control panels are essential in achieving seamless automation."

Benefits of employing PLC control panels extend beyond mere efficiency. They offer flexibility in programming, allowing adjustments to production processes without extensive downtime. Additionally, the centralized control they provide simplifies monitoring, which can lead to reduced operational costs. However, some organizations struggle to fully utilize their capabilities. The challenge lies in ensuring proper training and support for personnel managing these systems. A failure to adapt can lead to underperformance.

In a world where automation is key, the importance of PLC control panels cannot be overstated. As companies increasingly rely on these technologies, understanding their benefits becomes crucial. Organizations must reflect on their current practices and consider how to enhance their use of PLC control panels.

Understanding PLC Control Panels and Their Role in Automation

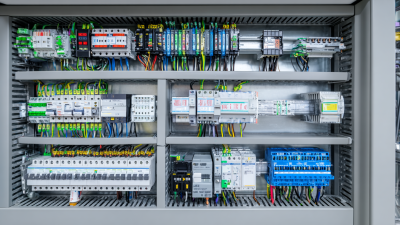

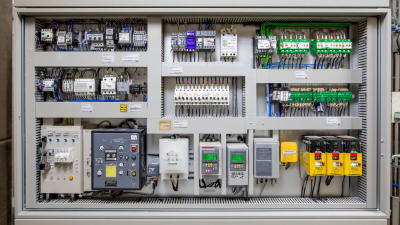

PLC control panels play a crucial role in automation systems. They serve as the brain behind various processes in manufacturing, utilities, and building management. According to recent industry reports, up to 75% of companies using PLCs report increased efficiency in their operations. This significant leap demonstrates their importance in modern automation.

These control panels allow real-time monitoring and control of machinery. They can process large volumes of data quickly. A PLC can manage multiple tasks at once, significantly reducing downtime. However, configuring these systems can be complex. Many users find themselves navigating a steep learning curve.

Tips: Consider training your staff regularly. It can improve their understanding of PLC systems. Use simulation software to practice before implementing changes. This can help minimize costly errors.

The flexibility of PLCs is another advantage. They can be programmed for specific tasks and easily adapted as needs change. Despite this, some operators still face challenges with outdated software. Keeping systems updated is essential for optimal performance. Neglecting maintenance can lead to system failures, which are costly.

Enhanced Efficiency and Productivity Through PLC Control Systems

PLC control panels have revolutionized automation systems. These panels enhance efficiency by streamlining complex processes. According to a report by the International Society of Automation, PLC systems can increase productivity by up to 30%. This result often comes from reduced downtime and faster response times.

With PLC systems, data can be analyzed in real-time. This capability allows companies to make informed decisions quickly. A study indicates that businesses experience a 25% reduction in operational costs after implementing PLC technology. However, it’s essential to recognize potential issues. System malfunctions may lead to unanticipated delays. Regular maintenance is crucial for maintaining performance.

Moreover, user training is often overlooked. Without proper knowledge, operators may not fully utilize these systems. This gap can prevent companies from achieving maximum efficiency. Investing in ongoing training is vital. While PLC control panels offer incredible benefits, neglecting these aspects may hinder overall productivity.

Improved Precision and Accuracy with PLC Technology

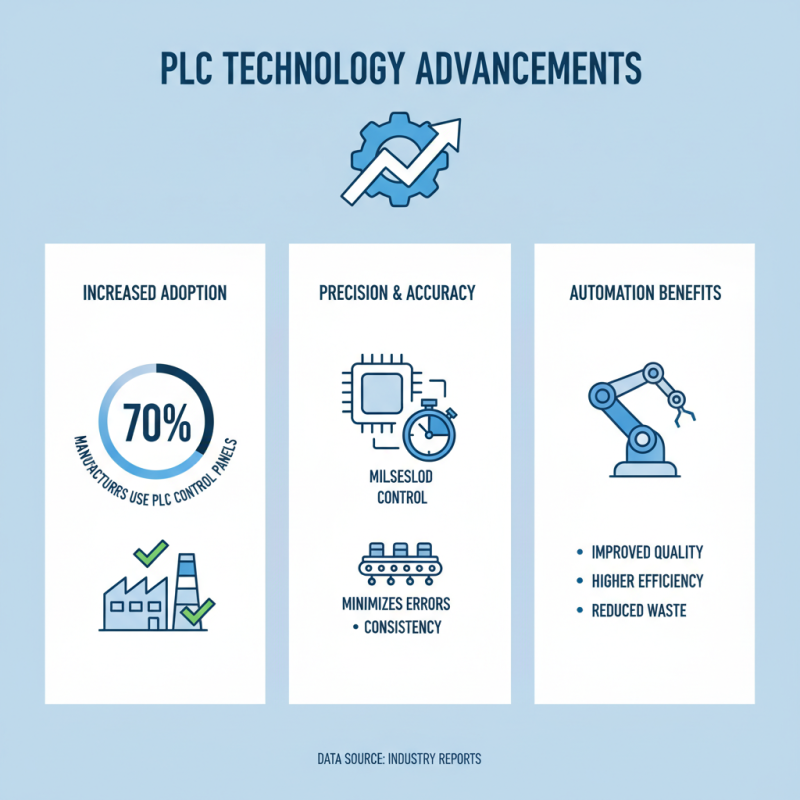

PLC technology has seen significant advancements in recent years. Industry reports indicate that 70% of manufacturers now leverage PLC control panels for improved precision. This shift highlights the growing reliance on automation systems to achieve higher accuracy in production processes. PLCs efficiently manage complex tasks, often down to the millisecond. This level of control helps minimize errors and enhances product consistency.

However, there are discussions around the challenges of implementing PLC systems. While many organizations experience higher efficiency, some may struggle with initial setup costs and training. For instance, companies often report a 15% increase in operational expenses during the transition phase. This can deter smaller enterprises from adopting this technology despite its benefits.

Moreover, data indicates that PLCs can reduce downtime by up to 25%, which is impressive yet not universal. Some sectors still face issues with software glitches and compatibility with older machines. These factors can impact the expected gains in precision, prompting a closer look at the planning and resources needed for effective implementation.

Greater Flexibility and Scalability in Automation Solutions

Automation systems are increasingly adopting PLC (Programmable Logic Controller) control panels. These panels offer greater flexibility and scalability, crucial for modern manufacturing. They allow businesses to easily adapt to changing production needs. According to a 2022 report by the International Society of Automation, flexible automation solutions can improve efficiency by up to 30%. This adaptability is vital as companies strive to remain competitive in a fast-paced market.

Tip: Regularly assess your automation requirements. This ensures that your PLC control panels can be upgraded or modified without significant downtime. The modular design of these systems supports easy updates, making it simpler to integrate new technology.

Scalability is another major benefit. As demand grows, companies can expand their automation systems without extensive redesign. A 2023 study indicated that nearly 70% of surveyed companies planned to expand their automation over the next two years. However, not all systems can support such growth effectively. Careful planning is essential to maximize your investments.

Tip: Invest in training for your team. Well-trained staff can better manage adjustments to the control systems. This not only enhances efficiency but also minimizes errors during transitions. Planning for both flexibility and scalability should be part of your long-term strategy. Every change requires careful consideration to ensure that operations continue smoothly.

Top 10 Benefits of Using PLC Control Panels for Automation Systems - Greater Flexibility and Scalability in Automation Solutions

| Benefit | Description | Impact Level |

|---|---|---|

| Improved Efficiency | PLC control panels optimize process control, leading to higher operational efficiency. | High |

| Flexibility | Easily reprogrammed for changing production needs, providing adaptability. | Moderate |

| Scalability | Easily expanded by adding more I/O modules or devices as needed. | High |

| Cost-effectiveness | Reduces downtime and maintenance costs through automation. | High |

| Enhanced Safety | Incorporates safety features to protect equipment and personnel. | High |

| Data Logging | Facilitates real-time monitoring and historical data collection. | Moderate |

| Quality Control | Improves product quality through consistent operation. | High |

| Integration | Seamlessly integrates with other automation systems and devices. | High |

| Remote Access | Allows remote monitoring and control to enhance operational capabilities. | Moderate |

| User-Friendly Interface | Simplifies user interaction with intuitive control panels. | Moderate |

Cost-Effectiveness and ROI from Implementing PLC Control Panels

PLC (Programmable Logic Controller) control panels are transforming

automation systems. Their cost-effectiveness is a major draw for industries today.

According to a report by the Automation Federation, companies can save up to

20% on operational costs by integrating PLC systems. This is due to streamlined

processes and reduced downtime.

The initial investment in PLC control panels may seem high. However, the return on investment (ROI) is substantial. Studies indicate that

businesses often see ROI within two years. Enhanced reliability increases production efficiency,

cutting unexpected expenses. A well-automated facility can operate with fewer errors. This is crucial in competitive markets.

Maintenance is another factor to consider. While PLCs require occasional updates, their longevity outweighs the costs. A survey from the

International Society of Automation highlights that companies using PLCs reported

fewer maintenance issues, saving an average of 15% on annual maintenance budgets.

Yet, it's important to recognize that not all automation solutions fit every scenario. Tailoring the

system to specific needs is vital for maximizing benefits.

Related Posts

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

Revolutionizing Manufacturing Control Systems Insights from the 138th China Import and Export Fair 2025

-

Understanding the Role of Automation Control Panels in Modern Industrial Systems

-

How to Master Panel PLC Programming: Tips and Techniques for Beginners

-

What is HMI Programming and How to Get Started with It