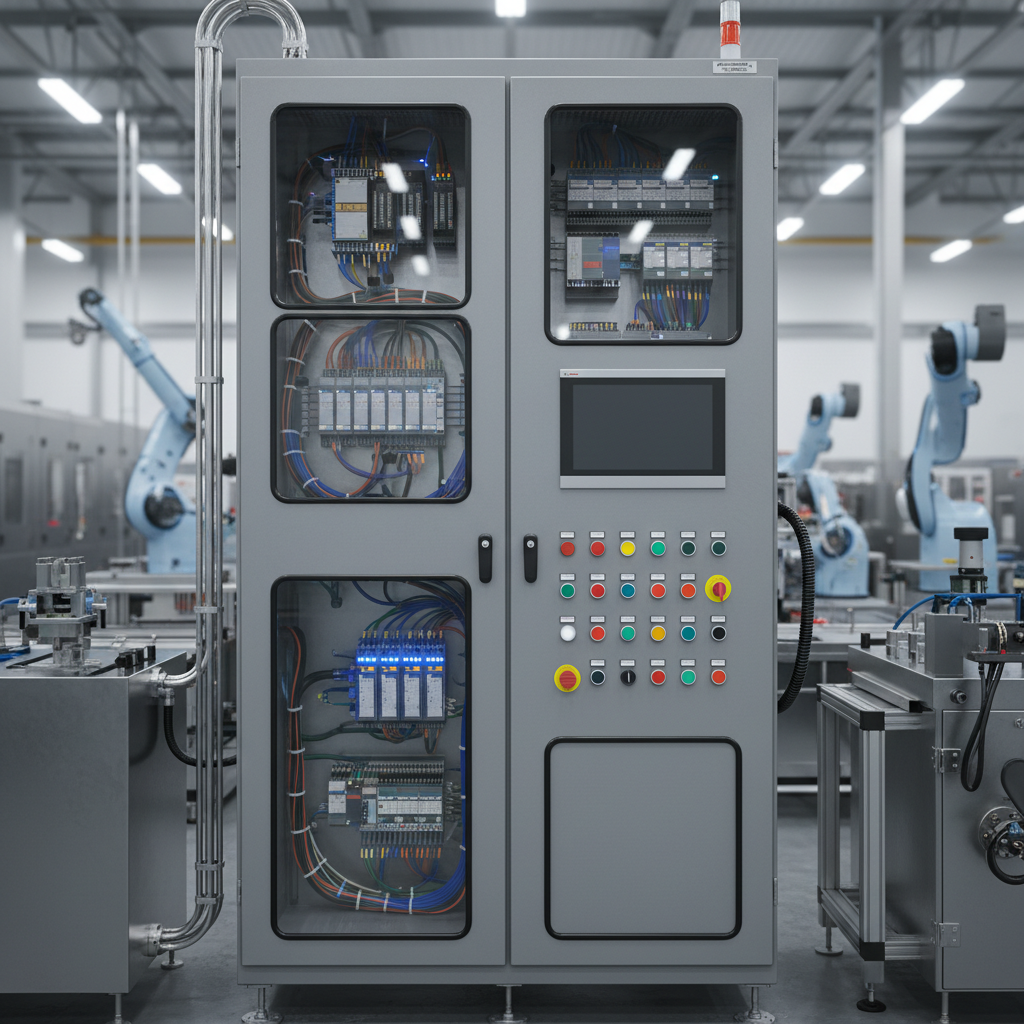

Top 10 Benefits of Using PLC Control Panels in Industrial Automation

In the realm of industrial automation, the advancement of technology continues to reshape operational efficiency and productivity. One of the pivotal components in this transformation is the PLC control panel. PLC, or Programmable Logic Controller, serves as the brain of automated systems, enabling seamless integration of machinery, enhancing control capabilities, and ultimately driving the overall success of industrial operations. As companies strive to remain competitive in an ever-evolving market, understanding the myriad benefits of utilizing PLC control panels becomes crucial.

The advantages of PLC control panels extend far beyond basic automation. They provide flexibility in programming, allowing businesses to adapt quickly to changing production needs without significant downtime. Furthermore, PLC control panels enhance reliability and maintenance efficiency, resulting in reduced operational costs. This is particularly important as industries look for sustainable solutions that not only boost productivity but also minimize environmental impact. In this outline, we will explore the top ten benefits of incorporating PLC control panels into industrial automation systems, illustrating how their implementation can lead to a smarter, more efficient future for manufacturing and production.

Advantages of Enhanced Process Control with PLC Panels

In the realm of industrial automation, the integration of Programmable Logic Controllers (PLCs) in control panels offers significant advantages that enhance process control. One of the key benefits is improved efficiency. With the global market for programmable logic controllers expected to grow from USD 11.7 billion in 2024 to USD 31.4 billion by 2034, it is evident that industries are recognizing the critical role PLCs play in streamlining operations. This growth underscores their capability to manage complex tasks with precision, allowing for more consistent production processes and reduced downtime.

Moreover, PLC control panels enable real-time monitoring and data collection, enhancing decision-making processes. By utilizing advanced technologies such as intelligent robotics and IoT integration, businesses can achieve greater operational insight. For instance, recent innovations have demonstrated that voice recognition technologies can be effectively integrated with PLC systems, facilitating hands-free control and greater flexibility in manufacturing environments.

As industries continue to adopt these sophisticated automation solutions, the enhanced process control offered by PLCs will play a pivotal role in driving productivity and efficiency across various sectors.

Improved Efficiency and Productivity through Automation

In the realm of industrial automation, the use of PLC (Programmable Logic Controller) control panels has become a cornerstone for enhancing efficiency and productivity. By integrating PLCs, manufacturers can streamline operations, minimize downtime, and ensure precise control over production processes. This technological advancement plays a pivotal role in enabling faster decision-making and reducing operational costs, directly contributing to overall productivity gains. Just as AI is transforming business landscapes by automating workflows and optimizing processes, PLCs similarly facilitate intelligent operations in industrial settings.

The implementation of PLC control panels also allows for real-time monitoring and adjustments, enhancing responsiveness to changing production demands. As industries increasingly adopt automation technologies, the potential for significant efficiency improvements becomes evident. Research indicates that automation can drive productivity by up to 20%, highlighting the importance of integrating advanced control systems like PLCs. By creating automated environments that eliminate repetitive tasks and minimize human error, companies can focus on innovation and strategic growth, leveraging these technologies to gain a competitive edge in their respective markets.

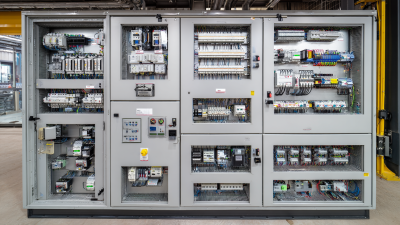

Streamlining Maintenance and Troubleshooting with PLC Technology

In the realm of industrial automation, Programmable Logic Controllers (PLCs) play a pivotal role in streamlining maintenance and troubleshooting processes. Data from a recent industry report suggests that organizations utilizing PLC control panels can decrease downtime by up to 30%, significantly enhancing overall productivity. This efficiency stems from the ability of PLCs to monitor system performance in real-time, allowing for immediate detection of anomalies. Quick identification of issues translates to faster repairs, thereby reducing operational costs and minimizing the impact on production lines.

When it comes to maintenance, PLC technology offers advanced diagnostics and troubleshooting features. With built-in self-diagnostic capabilities, operators can easily pinpoint problems, avoiding the guesswork often associated with traditional systems. A study by the Automation Federation found that companies leveraging PLC controls report a 25% reduction in maintenance-related expenses. These systems not only alert personnel to errors but also provide suggested corrective actions, thus facilitating a more proactive approach to equipment care.

Tips: To maximize the benefits of PLC systems, regularly update the software to ensure access to the latest features and security enhancements. Additionally, invest in training for staff on PLC operation and troubleshooting techniques, as this can further decrease response times and improve maintenance efficiency.

Real-time Data Monitoring and Analysis for Informed Decision Making

The implementation of PLC control panels in industrial automation significantly enhances real-time data monitoring and analysis, serving as a critical asset for informed decision-making. By integrating these advanced control systems, organizations can collect and analyze data instantaneously, allowing them to respond quickly to operational challenges and optimize processes efficiently. This capability not only improves productivity but also aids in identifying trends and patterns that can inform strategic planning.

Moreover, the growth of predictive analytics within the industrial sector underscores the need for effective real-time data utilization. As companies increasingly rely on cloud and on-premise solutions for data handling, the ability to leverage real-time insights becomes paramount. Businesses can now harness these insights to determine what strategies are working, allocate resources more effectively, and ultimately foster innovation. With real-time analysis, organizations can make well-informed decisions that drive growth and enhance their competitive edge in a rapidly evolving marketplace.

Top 10 Benefits of Using PLC Control Panels in Industrial Automation

| Benefit | Description | Impact on Operations | Examples of Application |

|---|---|---|---|

| Real-time Monitoring | Continuous tracking of performance and conditions of machinery. | Improves response times and operational efficiency. | Manufacturing plants, chemical processing. |

| Data Analysis | Analysis of data trends to optimize processes. | Enhances decision-making based on factual insights. | Food processing, energy management. |

| Increased Efficiency | Automation of repetitive tasks and processes. | Reduces labor costs and minimizes errors. | Assembly lines, quality control systems. |

| Improved Safety | Built-in safety measures for hazardous tasks. | Reduces workplace accidents and injuries. | Chemical plants, heavy machinery operation. |

| Remote Access | Control and monitor equipment from remote locations. | Allows for flexible management and oversight. | Utilities, large scale manufacturing. |

| Scalability | Easily add more control points and features. | Facilitates growth and expansion of operations. | Modular production systems, robotics. |

| Cost Savings | Lower operational and maintenance costs over time. | Increased profitability and return on investment. | Any automated assembly or processing line. |

| Enhanced Quality Control | Real-time quality checks integrated into machinery. | Improves product quality and reduces waste. | Textile manufacturing, pharmaceuticals. |

| Data Security | Secure data collection and transmission protocols. | Protects sensitive operational data from breaches. | Finance, sensitive manufacturing data control. |

| Integration with IoT | Seamless connection with IoT devices for enhanced capabilities. | Enables smarter, more connected operations. | Smart factories, intelligent logistics. |

Scalability and Flexibility of PLC Control Systems for Future Growth

As industries evolve, the need for scalable and flexible control systems becomes increasingly critical. PLC (Programmable Logic Controller) control panels offer a unique advantage in this regard, allowing businesses to easily adapt and expand their operations without significant overhauls. These systems can be upgraded or modified to accommodate new processes or technologies, ensuring that companies remain competitive in a rapidly changing market. This adaptability is particularly important for manufacturers looking to incorporate emerging technologies such as IoT and AI into their production lines.

Furthermore, the modular design of PLC control systems enables seamless expansion. When a business grows or requires additional functionality, PLCs can be integrated with minimal disruption. This means that organizations can manage increased production demands and implement new strategies quickly, without the need for complete system replacements. Such flexibility not only reduces downtime but also ensures that investments in automation support long-term growth objectives. By choosing PLC control panels, companies position themselves to navigate the future with confidence, leveraging technology that evolves in line with their operational needs.

Related Posts

-

What is the Importance of PLC Programming in Modern Automation

-

Understanding the Role of Automation Control Panels in Modern Industrial Systems

-

Exploring the Evolution of Control Panels: Industry Insights and Future Trends in Automation Technology

-

Understanding PLC Control Panels: Essential Components and Their Impact on Automation Efficiency

-

Enhancing Industrial Efficiency: The Future of PLC Control Systems in Smart Manufacturing

-

The Future of HMI Panel Innovation and Automation