Ultimate Guide to Choosing Control Cubicles for Maximum Efficiency

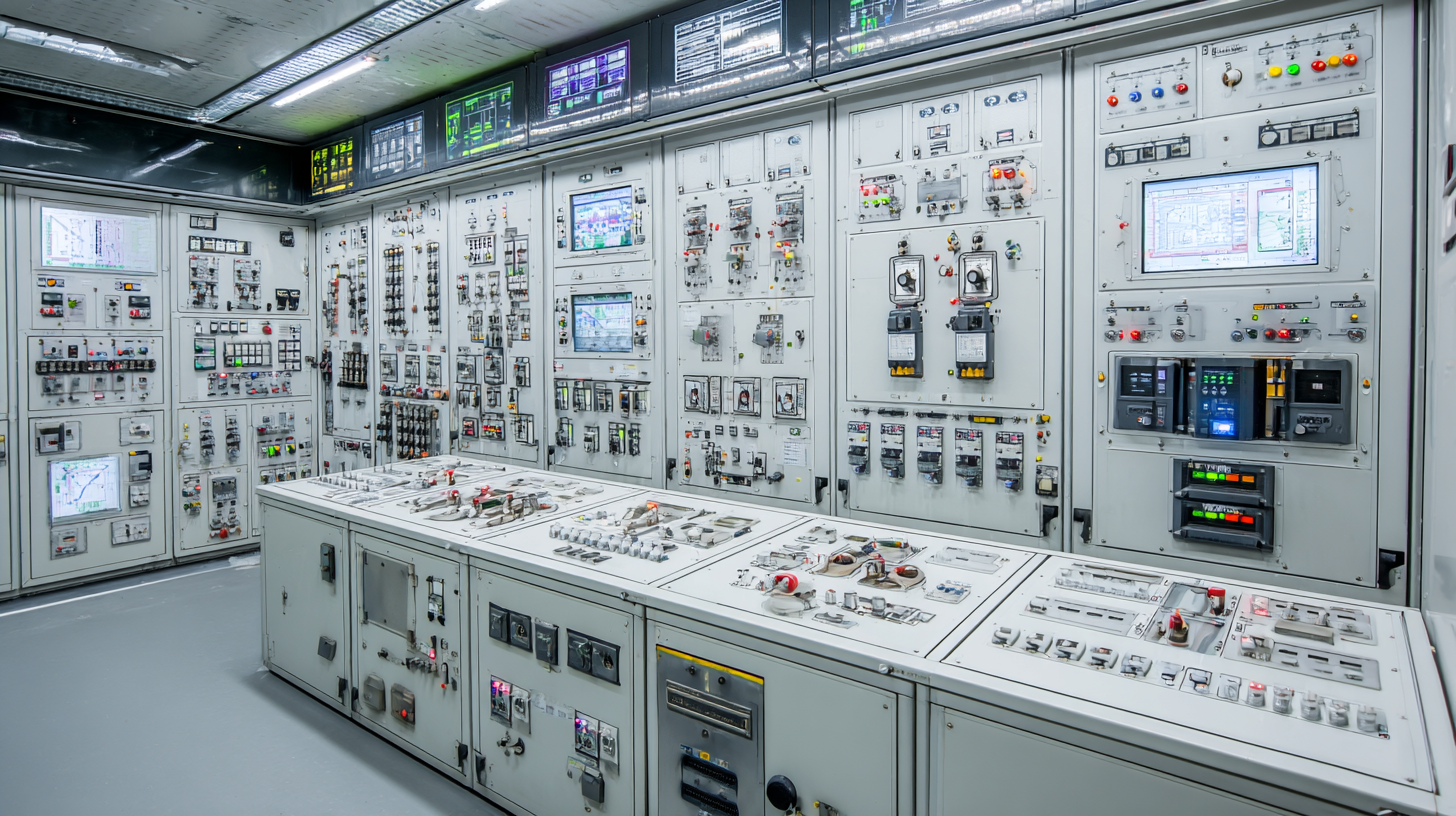

In today's fast-paced industrial environment, optimizing workspace efficiency is paramount, and one key component in achieving this is the strategic selection of control cubicles. According to a report by the International Facility Management Association, well-designed control workspaces can boost worker productivity by up to 20%, demonstrating the critical role that control cubicles play in operational success. Furthermore, a study by the American Society of Interior Designers highlights that the right configuration can enhance communication flow and collaboration, significantly impacting decision-making processes. As industries continue to evolve and adapt to new technological advancements, understanding the intricacies of control cubicles—from ergonomic design to strategic placement—will be essential for maximizing operational efficiency. This ultimate guide aims to provide insights and expert recommendations for selecting the most effective control cubicles tailored to your organizational needs.

Understanding Control Cubicles: Key Features for Optimal Performance

Control cubicles are integral to efficient operations in various industries, housing essential equipment and providing a functional workspace. When selecting control cubicles, it is crucial to understand key features that enhance performance. One vital aspect is ergonomics; a well-designed control cubicle promotes operator comfort and minimizes fatigue, leading to increased productivity. Features such as adjustable desks, adequate lighting, and support for natural body movements can make a significant difference in daily operations.

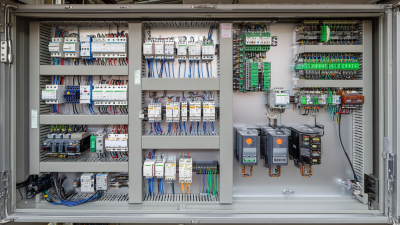

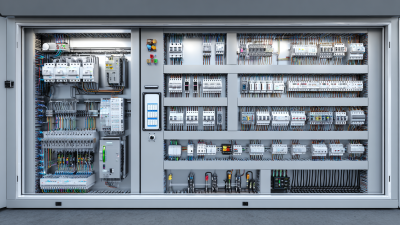

Another important feature of control cubicles is the integration of technology. Modern cubicles should accommodate equipment such as monitors, communication devices, and control panels without compromising usability. High-quality cable management systems can prevent clutter, ensuring a clear workspace and improving overall safety. Additionally, incorporating modular designs allows for flexibility, enabling organizations to adapt the workspace as their needs evolve. By focusing on these key features, businesses can ensure that their control cubicles not only meet operational requirements but also promote optimal employee performance.

Factors to Consider When Selecting Control Cubicles for Your Operations

When selecting control cubicles for your operations, several critical factors must be taken into account to ensure maximum efficiency. According to a report by the Control Room Design Institute, ergonomics plays a pivotal role in enhancing operator performance and reducing fatigue. Properly designed control cubicles should facilitate easy access to controls and displays while minimizing physical strain. The use of adjustable furniture can help accommodate different operator needs, potentially increasing productivity by up to 15% as noted in their findings.

Another vital consideration is technology integration. With advancements in automation and real-time data monitoring, control cubicles must be adaptable to incorporate various technological interfaces. A survey by the International Society for Automation indicated that organizations utilizing advanced technology within their control environments experience a 20% reduction in response time to critical events. Therefore, selecting cubicles that can support modern communication tools and visualization systems is essential for optimizing operational efficiency.

Top Tips for Maximizing Space and Ergonomics in Control Cubicle Design

When designing control cubicles, maximizing space and ergonomics is crucial for enhancing efficiency. One key aspect is the layout. An open design that allows for easy movement can prevent congestion and create a more comfortable working environment. Utilizing modular furniture enables flexibility, allowing operators to customize their workspace according to their specific needs. Additionally, integrating storage solutions into the cubicle design not only declutters the work area but also ensures that essential tools and documents are readily accessible.

Ergonomics also plays a significant role in control cubicle design. Adjustable furniture, such as desks and chairs, can cater to various body types and preferences, promoting better posture and reducing strain during long hours of operation. Investing in hydraulic or sit-stand desks can enhance comfort and improve productivity. Furthermore, proper lighting is essential; incorporating natural light where possible and using task lighting can help reduce eye strain and fatigue. By prioritizing these elements, control cubicles can be transformed into efficient, user-friendly spaces that support optimal performance.

Ultimate Guide to Choosing Control Cubicles for Maximum Efficiency

| Dimension | Recommended Value | Considerations |

|---|---|---|

| Cubicle Width | 72 - 96 inches | Allows for multiple monitors and ergonomic setup. |

| Cubicle Depth | 60 - 80 inches | Provides ample space for equipment and movement. |

| Height | 54 - 66 inches | Ensures privacy while maintaining openness. |

| Desk Height | 28 - 30 inches | Standard ergonomic height for sitting position. |

| Monitoring Equipment Space | At least 40 inches width | Space for multiple screens without overcrowding. |

| Cable Management | Integrated solutions preferred | Keeps workspace tidy and reduces hazards. |

| Lighting | 400-500 lux | Encourages productivity and reduces eye strain. |

| Acoustic Panels | Recommended | Reduces noise pollution for better focus. |

Enhancing Efficiency: Technologies to Integrate into Control Cubicles

When selecting control cubicles, integrating advanced technologies can significantly enhance operational efficiency. According to a report by Research and Markets, the global market for control systems is anticipated to reach $155 billion by 2025, underscoring the importance of choosing the right technologies for control cubicles. Implementing real-time monitoring systems can lead to an improvement of up to 30% in productivity by streamlining data collection and analysis.

Tips: Ensure that your control cubicles are equipped with user-friendly interfaces and automation software that offer customizable dashboards. This can facilitate quicker decision-making for operators by providing instant access to critical data.

Additionally, incorporating IoT devices into control cubicles enables seamless communication between equipment. A recent study by McKinsey indicated that IoT integration can reduce maintenance costs by up to 25% and enhance system reliability. This integration empowers operators with predictive analytics, allowing them to foresee equipment failures before they occur, thus maximizing uptime.

Tips: Evaluate prospective technologies for compatibility with existing systems to avoid costly downtime during implementation. Investing in scalable technological solutions will ensure your control cubicles can adapt to future advancements and changing operational needs.

Efficiency Enhancements in Control Cubicles

Maintenance Best Practices for Long-lasting Control Cubicle Solutions

When it comes to ensuring the longevity and efficiency of control cubicles, maintenance best practices play a crucial role. Regular inspections are essential to identify potential issues before they escalate. This includes checking for wear and tear on components, ensuring that all electrical connections are secure, and verifying that all safety features are functional. Additionally, establishing a routine cleaning schedule can prevent the accumulation of dust and debris, which can hinder performance and lead to increased wear on equipment.

Moreover, training staff responsible for the upkeep of control cubicles is vital. Proper training ensures that personnel are well-versed in troubleshooting common issues and following manufacturer guidelines for maintenance tasks. Documenting all maintenance activities not only helps in tracking the performance over time but also aids in identifying patterns that may indicate underlying problems. These proactive measures can significantly enhance the operational lifespan of control cubicles while maximizing their efficiency in various industrial applications.

Related Posts

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency

-

How to Optimize Your Manufacturing Efficiency with VFD Control Panels

-

How to Optimize Your Electrical Control Panel Design for Maximum Efficiency and Safety

-

How to Create Efficient Electrical Control Panel Designs for Optimal Performance

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

How to Master PLC Controller Programming for Industrial Automation