10 Control Engineering Tips to Enhance Your System Performance and Efficiency

In the ever-evolving landscape of industrial automation, control engineering plays a pivotal role in shaping system performance and efficiency. As industries strive for heightened operational excellence, the deployment of advanced control strategies has become increasingly essential. According to a report by the International Society of Automation, implementing effective control engineering practices can enhance system reliability by up to 30%, while simultaneously reducing operational costs by an impressive 20%. These statistics underscore the necessity for engineers to adopt innovative methodologies that not only optimize performance but also drive sustainability in processes.

As we look towards 2025, the demand for sophisticated control systems is projected to escalate, with a survey by MarketsandMarkets indicating a compound annual growth rate (CAGR) of 9.2% in the global control systems market. This growth highlights the importance of staying abreast of emerging trends and technological advancements in control engineering. By mastering key control engineering techniques, professionals can not only improve system functionality but also contribute to the broader goals of efficiency and sustainability in their respective industries. This article aims to provide ten actionable control engineering tips that can effectively enhance your system's performance and efficiency in this competitive landscape.

Strategies for Improving Control System Stability and Responsiveness

In the realm of control engineering, ensuring system stability and responsiveness is paramount for optimizing performance. According to a report by the International Society of Automation, nearly 60% of control systems fail to meet their design specifications due to issues related to stability. Implementing robust feedback loops can significantly enhance system stability. These loops adjust the control actions based on real-time outputs, fundamentally reducing the risk of oscillations and overshoot. By leveraging advanced algorithms, such as PID controllers fine-tuned using simulation data, engineers can achieve a more stable operational environment.

Furthermore, responsiveness can be markedly improved through the application of predictive control strategies. A study from the IEEE has shown that predictive control can reduce response time by up to 30% in dynamic systems, like those used in manufacturing. By utilizing models that forecast future system behavior, engineers can make timely adjustments that preempt instability, thereby enhancing overall system efficacy. Proper calibration and ongoing system monitoring are also critical, ensuring that changes in environmental conditions or system loads do not compromise responsiveness. These strategies collectively facilitate a well-rounded approach to improving control system performance, where both stability and responsiveness are prioritized.

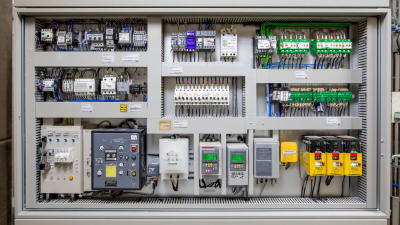

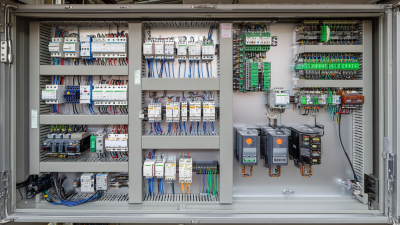

Best Practices for Implementing Modular Control Architectures in Complex Systems

Implementing modular control architectures in complex systems is essential for enhancing performance and efficiency. A modular approach allows for the division of complex control tasks into smaller, manageable segments. This not only simplifies the design process but also facilitates easier maintenance and upgrades of individual modules without affecting the entire system. Each module can be independently developed, tested, and optimized, thereby accelerating the overall system integration and reducing the risk of errors.

To successfully implement modular control architectures, it's crucial to establish clear interfaces between the modules. These interfaces should be well-defined and standardized to ensure seamless communication and interoperability. Additionally, employing simulation tools can help in visualizing the system's behavior under different configurations, allowing engineers to identify potential issues early in the process. Emphasizing a robust testing phase before full deployment fosters confidence in the modular design, ultimately leading to improved reliability and performance of complex systems in various applications.

Leveraging Real-Time Data Analytics to Optimize Control System Performance

In today’s rapidly evolving technological landscape, leveraging real-time data analytics has become crucial for optimizing control system performance. By integrating advanced data gathering techniques, engineers can monitor system variables instantaneously, allowing for timely adjustments and improvements. According to a 2022 report by MarketsandMarkets, the global real-time analytics market is projected to grow from $10.4 billion in 2021 to $22.4 billion by 2026, reflecting the increasing importance of data-driven decision-making in control engineering.

The deployment of real-time data analytics not only enhances system responsiveness but also improves overall efficiency. For instance, a study from the International Society of Automation (ISA) revealed that organizations employing real-time monitoring and analytics reported an increase in operational efficiency by up to 30%. By continuously analyzing performance data, engineers can identify inefficiencies, predict potential failures, and optimize control algorithms, ultimately leading to lower operational costs and extended equipment lifespan. Embracing these technologies positions organizations to excel in a competitive landscape, leveraging insights that drive smarter, more efficient control systems.

10 Control Engineering Tips to Enhance Your System Performance and Efficiency

| Tip No. | Tip Description | Expected Outcome | Real-Time Data Use |

|---|---|---|---|

| 1 | Implement PID Control Tuning | Improved stability and response time | Utilize real-time feedback for dynamic tuning |

| 2 | Deploy Predictive Maintenance | Reduced downtime and maintenance costs | Analyze real-time sensor data for anomaly detection |

| 3 | Optimize Control Algorithms | Enhanced system responsiveness and efficiency | Incorporate data-driven insights for algorithm adjustments |

| 4 | Integrate IoT Devices | Real-time monitoring and control capabilities | Utilize data from IoT sensors for immediate analytics |

| 5 | Enhance User Interface | Improved user engagement and error reduction | Utilize user data for tailoring UI elements |

| 6 | Implement Adaptive Control Techniques | Increased robustness against disturbances | Real-time performance data informs adaptive algorithms |

| 7 | Establish Data Redundancy | Increased system reliability and data integrity | Monitor redundancy data for failover scenarios |

| 8 | Utilize Simulation Tools | Enhanced design workflow and risk assessment | Feed real-time data into simulations for validation |

| 9 | Streamline Communication Protocols | Faster data exchange and decision-making | Analyze data traffic to optimize protocols |

| 10 | Conduct Regular Training | Improved workforce skill and operational efficiency | Track training effectiveness through performance data |

Utilizing Advanced Control Techniques for Enhanced Process Efficiency

Utilizing advanced control techniques has become essential for enhancing process efficiency in various industrial sectors. The integration of advanced process controls can significantly optimize operations, particularly in energy and material management. For instance, state-of-the-art control mechanisms, such as robust model predictive control combined with deep learning, have shown promising results in increasing performance and adaptability in energy systems, especially in hybrid power networks. The evolving landscape of control engineering necessitates a comprehensive approach to maximize the value derived from these advanced techniques.

One effective tip for enhancing system performance is to leverage PID controllers, which remain vital in today’s automation landscape. Despite the advances in artificial intelligence and IoT, PID controllers provide critical automated responses that ensure stability and accuracy in processes. Additionally, implementing fuzzy logic for adaptive speed control in brushless DC motors has proven beneficial in boosting electric vehicle performance. Employing these tried-and-true methods in conjunction with modern technologies can yield significant improvements in both efficiency and performance across various applications.

Emphasizing the Importance of Regular Maintenance and Calibration in Control Systems

Regular maintenance and calibration are paramount for ensuring optimal performance and efficiency in control systems, particularly in industries facing precision challenges, such as semiconductor manufacturing. As highlighted by recent trends, the demand for advanced motion control solutions has surged due to the growing need for accuracy, productivity, and stability. For instance, the integration of cutting-edge optical encoder technology has become essential for maintaining high performance in precision equipment. This is crucial in a landscape where even minor discrepancies can lead to significant operational failures.

According to industry reports, the semiconductor sector is witnessing rapid advancements, with a projected compound annual growth rate (CAGR) of 7.6% for various sensor markets by 2032. These sensors are vital for maintaining air quality and monitoring environmental conditions which directly impact equipment efficiency. Regular calibration and maintenance ensure that these systems operate within their intended parameters, thereby enhancing reliability and overall productivity. Implementing structured maintenance protocols can ultimately lead to substantial long-term savings and improved system performance across various applications.

Related Posts

-

Mastering Control Engineering 10 Essential Digital Tips for Boosting Efficiency and Reducing Costs

-

What is Control Engineering and Why It Matters in Modern Industry

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

What is the Importance of PLC Programming in Modern Automation

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

How to Optimize Your Electrical Control Panel Design for Maximum Efficiency and Safety