How to Achieve Effective Distribution Control in Supply Chain Management

In today's competitive landscape, effective distribution control has emerged as a critical component of successful supply chain management. As organizations strive to enhance efficiency and customer satisfaction, the challenge of managing the distribution process becomes increasingly complex. Experts in the field emphasize the importance of robust distribution control mechanisms to streamline operations and reduce costs. John Smith, a leading authority in supply chain logistics, stated, "Without a well-implemented distribution control strategy, businesses risk losing not only their efficiency but also their customer trust."

Addressing these challenges requires a comprehensive understanding of the methodologies and technologies that can optimize distribution processes. The integration of advanced analytics and real-time tracking systems enables businesses to gain visibility over their distribution channels, facilitating timely decision-making and enhancing overall responsiveness. As companies navigate the intricacies of the supply chain, the implementation of effective distribution control strategies can significantly influence their operational success and market positioning.

Ultimately, mastering distribution control is not merely about tracking goods; it encompasses a broader approach that aligns logistics, inventory management, and customer service. By prioritizing distribution control, organizations can achieve higher levels of efficiency, reduce operational risks, and deliver exceptional value to their customers. As such, the pursuit of effective distribution control methods remains a top priority for supply chain professionals aiming to thrive in an ever-evolving market.

Understanding the Importance of Distribution Control in Supply Chains

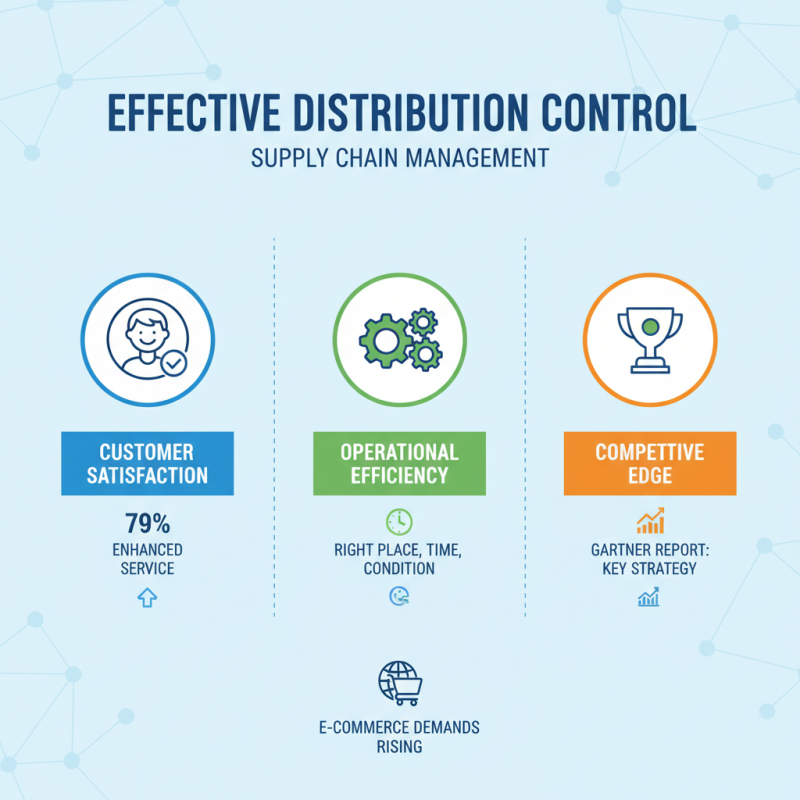

Effective distribution control is vital in supply chain management as it directly impacts customer satisfaction and operational efficiency. According to a report by Gartner, supply chain leaders cite effective distribution strategies as key to achieving a competitive edge, with 79% of organizations recognizing that optimized distribution processes enhance customer service levels. Proper distribution control ensures that products arrive at the right place, at the right time, and in the right condition, which is critical in today's fast-paced market where e-commerce demands are continually rising.

Furthermore, the consequences of poor distribution control can be significant. A study conducted by the Council of Supply Chain Management Professionals (CSCMP) found that the cost of inefficient distribution systems can lead to losses of up to 30% in revenue. This highlights the importance of leveraging technology and data analytics to monitor and refine distribution processes. By employing advanced tools such as real-time tracking and predictive analytics, companies can enhance their responsiveness to market demands and minimize delays, ultimately resulting in better inventory management and reduced operational costs.

Key Principles of Effective Distribution Control Strategies

Effective distribution control in supply chain management hinges on several key principles that ensure products reach their destinations in an efficient and timely manner. One essential principle is the integration of technology within distribution systems. Utilizing advanced software and automation tools can streamline processes, reduce errors, and enhance visibility throughout the supply chain. This technological approach allows for real-time tracking and informed decision-making, enabling businesses to respond swiftly to any disruptions or changes in demand.

Another critical aspect is the establishment of strong relationships with logistics partners. Collaborating closely with transporters, warehouses, and distributors facilitates better planning and communication, which are vital for effective distribution control. By nurturing these partnerships, businesses can achieve improved flexibility in their supply chain, allowing them to adapt to variations in supply and demand more effectively. Additionally, fostering a culture of continuous improvement within the organization can lead to the identification of inefficiencies and the implementation of best practices that enhance distribution performance.

Distribution Control Effectiveness in Supply Chain Management

This chart illustrates the effectiveness of various distribution control metrics within supply chain management. High scores in inventory accuracy and order fulfillment suggest strong performance, while lower scores in transportation costs and return rates indicate areas for potential improvement.

Technological Tools for Enhancing Distribution Control

In the modern landscape of supply chain management, effective distribution control is increasingly reliant on the integration of advanced technological tools. According to a McKinsey report, companies that integrate digital technologies in their supply chain processes can improve their efficiency by up to 30%. Key technologies such as IoT, artificial intelligence, and blockchain are at the forefront of this transformation, enabling enhanced visibility and real-time tracking of inventory and shipments.

IoT devices facilitate seamless communication across the supply chain by providing real-time data on product location, temperature, and other critical variables. This level of transparency allows organizations to respond swiftly to disruptions and optimize their distribution strategies. Meanwhile, artificial intelligence algorithms can analyze large datasets to forecast demand more accurately, ensuring that distribution centers are stocked appropriately, thus reducing excess inventory costs by as much as 20%, as noted in a report by Deloitte. Additionally, the adoption of blockchain technology ensures secure and immutable records of transactions, fostering trust among stakeholders and enhancing accountability in the distribution process.

The synergy of these technological tools is revolutionizing inventory management and distribution control. Business leaders must leverage these innovations to enhance operational resilience, improve customer satisfaction, and sustain competitive advantages in an increasingly complex market environment. As the supply chain continues to evolve, embracing these technologies will be crucial for achieving effective distribution control.

Challenges in Achieving Distribution Control and Solutions

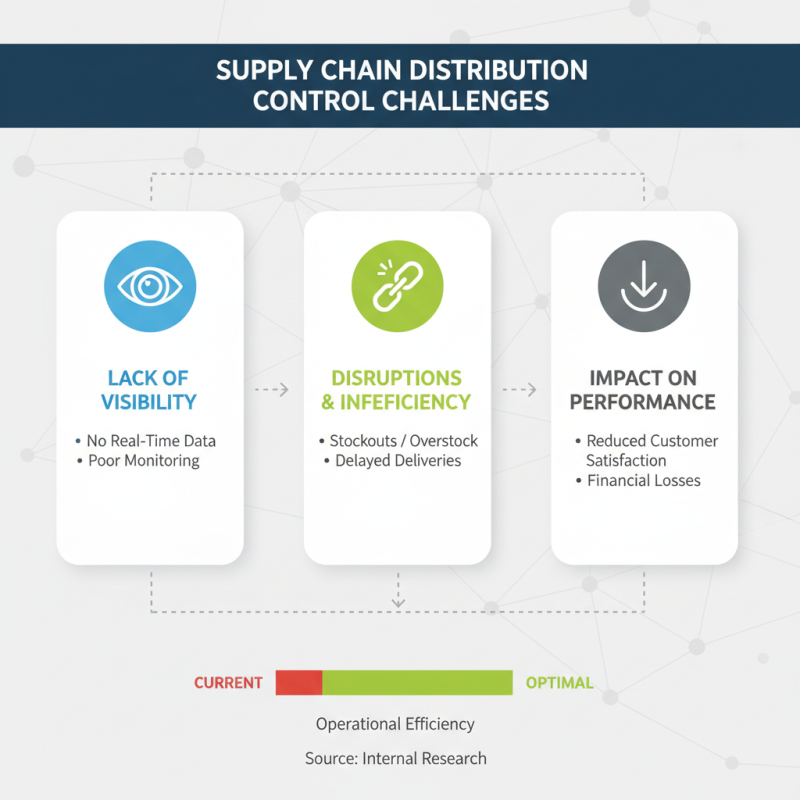

Achieving effective distribution control in supply chain management presents several challenges that can hinder operational efficiency and customer satisfaction. One significant challenge is the lack of visibility across the supply chain. Without real-time data and effective monitoring systems, companies struggle to track inventory levels, delivery status, and potential disruptions. This can lead to stockouts or overstock situations, disrupting the flow of goods and impacting financial performance.

To tackle these visibility issues, organizations can implement advanced technologies such as IoT devices and data analytics. These tools enable better tracking of inventory and shipments, providing insights that help to make informed decisions promptly. Another challenge is managing demand fluctuations. Seasonal changes, economic shifts, and unforeseen events can drastically alter demand patterns, making it difficult to align distribution strategies effectively.

**Tips for Success:** To manage demand fluctuations effectively, businesses should adopt a flexible distribution strategy that can quickly adapt to changing market conditions. Establishing strong relationships with suppliers and distributors can also help cushion the impact of unpredictable demand. Regularly reviewing sales data and market trends will aid in forecasting, reducing the risk of either surplus or deficit in inventory.

Furthermore, ensuring robust communication among all supply chain partners is vital. Miscommunication can lead to delays and inefficiencies. Implementing a centralized communication platform can help maintain clear lines of dialogue and streamline operational processes, leading to more effective distribution control.

Best Practices for Monitoring and Optimizing Distribution Processes

Effective distribution control is vital in supply chain management, as it not only minimizes costs but also enhances customer satisfaction. A 2022 report from the Council of Supply Chain Management Professionals (CSCMP) highlights that companies with optimized distribution processes can reduce operating costs by up to 20%. To achieve this, organizations should focus on continuous monitoring and performance metrics to identify inefficiencies. Utilizing real-time data analytics helps organizations track inventory levels, order fulfillment times, and transportation costs, allowing for quicker decision-making and adjustments.

Tips: Implement a centralized dashboard for real-time visibility into your distribution network. This will enable teams to monitor key performance indicators (KPIs) such as order accuracy and delivery lead times, ensuring that any deviations from the norm can be addressed promptly.

Moreover, adopting advanced forecasting methods plays a crucial role in optimizing distribution. According to the Aberdeen Group, companies with robust forecasting capabilities improve their inventory turnover rates by 30% compared to those without. This not only improves product availability but also reduces excess inventory, which can lead to financial losses. Regularly revisiting and refining forecasting models based on market trends and historical data is essential for maintaining an agile supply chain.

Tips: Engage in collaborative planning with suppliers and partners to refine demand forecasts. This coordinated effort can enhance accuracy and make distribution processes more resilient to fluctuations in demand.

How to Achieve Effective Distribution Control in Supply Chain Management - Best Practices for Monitoring and Optimizing Distribution Processes

| Best Practice | Description | Key Metrics | Implementation Tips |

|---|---|---|---|

| Real-time Tracking | Implementing GPS and RFID technology for real-time visibility of inventory. | Inventory Turnover Rate, Order Fulfillment Rate | Choose reliable tracking software and ensure integration with existing systems. |

| Demand Forecasting | Using historical data and analytics to predict future demand accurately. | Forecast Accuracy, Backorder Rate | Regularly update forecasting methods based on recent data trends. |

| Supplier Collaboration | Engaging suppliers in planning processes to align inventory and production. | Lead Time, Supplier Quality Rating | Create regular communication channels and joint planning sessions. |

| Automated Inventory Management | Utilizing software solutions to monitor and manage inventory levels automatically. | Stock Accuracy, Inventory Days | Choose a scalable solution that fits your supply chain size. |

| Customer Feedback Loop | Collecting and analyzing feedback from customers to improve services. | Customer Satisfaction Score, Net Promoter Score | Implement regular surveys and create a protocol for responding to feedback. |

Related Posts

-

Top Strategies for Effective Distribution Control in Global Supply Chains

-

The Future of HMI Panel Innovation and Automation

-

How to Master PLC Controller Programming for Industrial Automation

-

2025 Top Power Control Systems: Innovations Driving Efficiency and Reliability

-

Unlocking the Secrets of Motor Power Efficiency for Sustainable Energy Solutions

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance