How to Create Efficient Electrical Control Panel Designs for Optimal Performance

In today's rapidly advancing industrial landscape, the importance of efficient electrical control panel design cannot be overstated. According to the International Electrotechnical Commission (IEC), improper design can lead to performance inefficiencies and increased operational costs, affecting overall productivity by as much as 20%. As automation and smart technology become increasingly integral to manufacturing processes, the demand for well-structured control panels is higher than ever. Reports from the National Electrical Manufacturers Association (NEMA) indicate a rising trend in the use of modular systems that enhance flexibility and facilitate quicker adaptations to changing operational needs.

This evolution in design practice not only helps in meeting regulatory standards but also optimizes energy consumption, ultimately contributing to sustainability goals. Therefore, developing a comprehensive understanding of effective electrical control panel design is crucial for engineers and manufacturers aiming to achieve optimal performance and reliability in their operations.

Understanding the Fundamentals of Electrical Control Panel Design

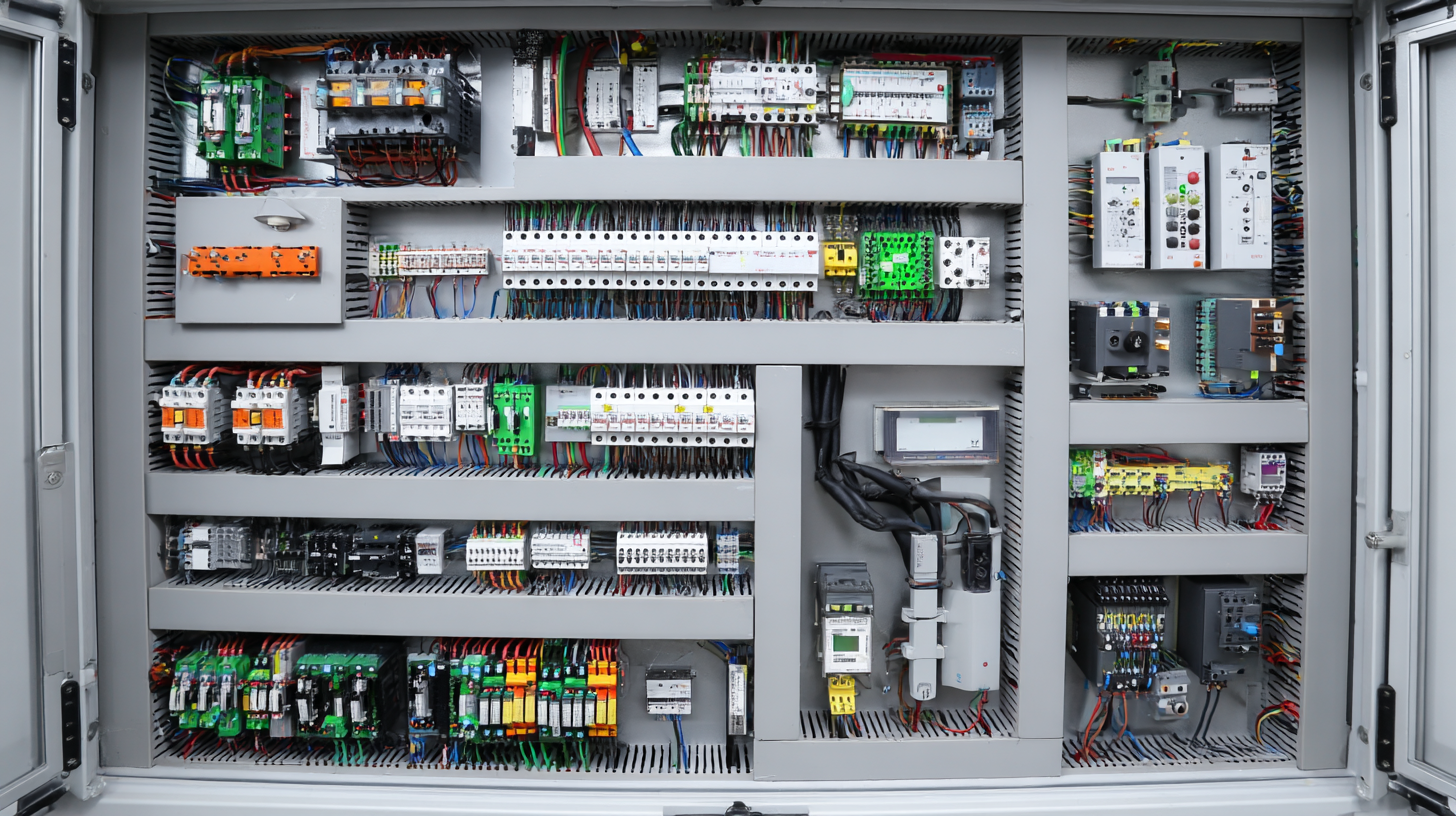

Understanding the fundamentals of electrical control panel design is critical for achieving optimal performance in any electrical system. At its core, electrical control panel design involves a thorough understanding of the components that regulate and manage electrical power. This includes selecting the appropriate circuit breakers, relays, and wiring methods suited for the specific application. Knowledge of electrical standards and regulations is also essential to ensure safety and compliance, thereby protecting both equipment and personnel.

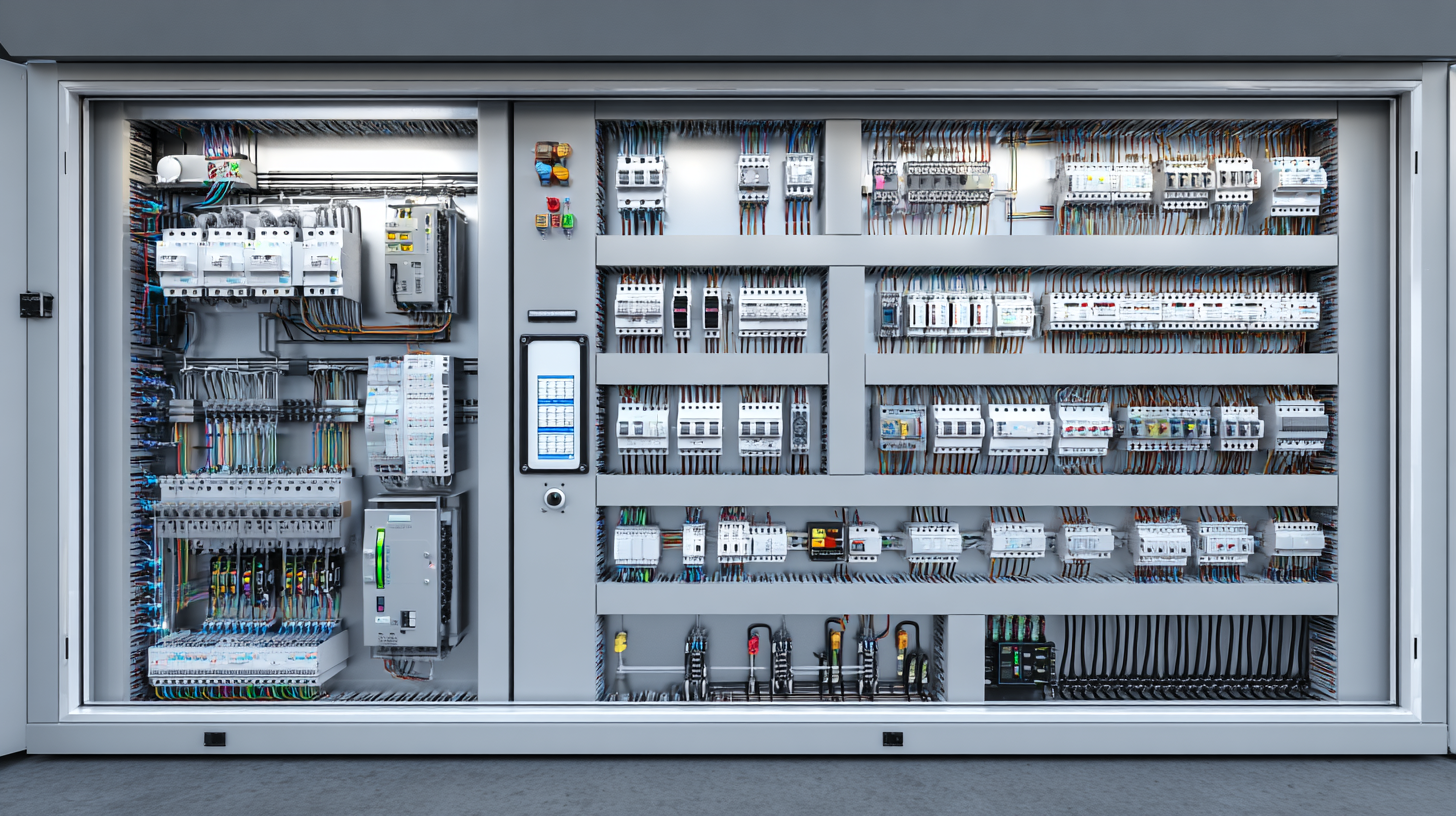

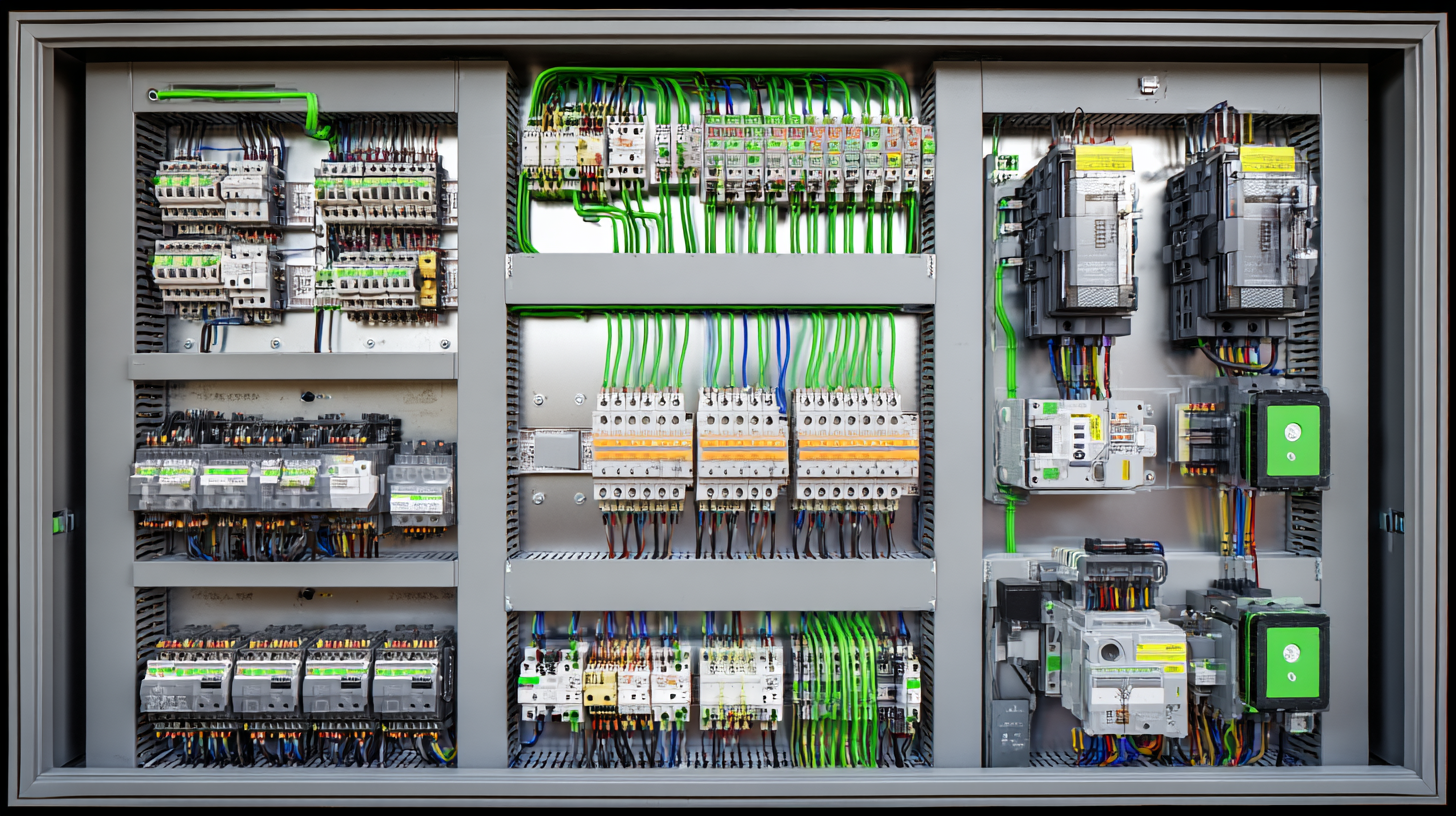

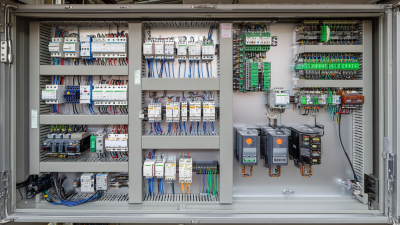

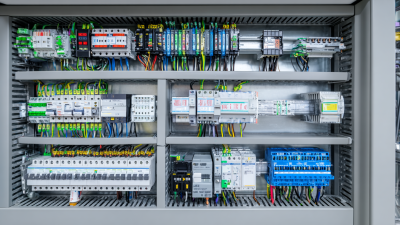

Another vital aspect of control panel design is the layout and organization of components within the panel. A well-structured design not only enhances accessibility for maintenance and troubleshooting but also contributes to efficient heat dissipation and overall reliability. Proper labeling and systematic wiring practices further support ease of use and reduce the chances of errors during installation or operation. By focusing on these fundamental principles, engineers can create control panels that not only perform effectively but also endure the test of time while minimizing downtime and maintenance costs.

Key Components to Include for Enhanced Functionality

When designing electrical control panels, incorporating key components is essential for enhancing functionality and ensuring optimal performance. Fundamental elements such as circuit breakers, relays, and terminal blocks play critical roles in managing electrical circuits safely and efficiently. Adding modern features like smart monitoring systems can significantly improve real-time performance metrics, allowing for quick diagnosis and maintenance of electrical issues.

When designing electrical control panels, incorporating key components is essential for enhancing functionality and ensuring optimal performance. Fundamental elements such as circuit breakers, relays, and terminal blocks play critical roles in managing electrical circuits safely and efficiently. Adding modern features like smart monitoring systems can significantly improve real-time performance metrics, allowing for quick diagnosis and maintenance of electrical issues.

Tips: Consider integrating modular designs for easy upgrades and repairs. Using color-coded wiring can also enhance clarity and facilitate troubleshooting, particularly in complex systems. Furthermore, including heat dissipation strategies, such as ventilation or cooling fans, can prevent overheating, thus prolonging the life of your components.

Incorporating emerging technologies into your designs can elevate performance. For instance, using advanced materials and components might not only improve reliability but also lead to more compact designs. Leveraging automation and intelligent control systems could streamline operations, making your control panels not only functional but also adaptable to future advancements in electrical applications.

Best Practices for Wiring and Layout Configuration

When designing an efficient electrical control panel, the wiring and layout configuration are paramount to achieving optimal performance. A well-organized layout not only enhances the panel's operational efficiency but also simplifies maintenance and troubleshooting. Start by planning the panel's internal layout thoroughly. Position components based on their function and frequency of access—keep frequently used devices like circuit breakers and relays within easy reach. Additionally, using modular components can facilitate future upgrades or replacements, allowing for a flexible design that can adapt to evolving needs.

Wiring practices play a crucial role in ensuring the reliability and safety of a control panel. It is essential to separate power and control wires to minimize interference and maintain signal integrity. Organizing wires with proper identification and labeling enhances clarity, thus reducing the likelihood of errors during installation and maintenance. Utilizing cable ducts or trays can also help manage wire runs efficiently, preventing tangling and ensuring a neat appearance. Adhering to industry standards and regulations throughout the design process will further ensure that the control panel operates safely and effectively in its intended application.

Ensuring Safety Standards and Compliance in Control Panels

In the realm of electrical control panel designs, ensuring safety standards and compliance is paramount for optimal performance. A report highlighting the insulated wire terminals market indicates a significant projected growth, with an estimated compound annual growth rate (CAGR) of 2.48% from 2025 to 2033, showcasing the increasing reliance on secure electrical infrastructure. This trend emphasizes the need for designs that prioritize safety features while also meeting stringent regulatory demands.

Moreover, as identity security emerges as a critical battlefield for organizations, threats posed by identity vulnerabilities are pressing concerns. A detailed analysis reveals that companies must adopt robust security measures to mitigate risks effectively. The incorporation of compliant control panels not only enhances operational efficiency but also aligns with safety regulations. As the public communication systems market grows, currently valued at an anticipated $206.6 million by 2025, adherence to safety standards becomes indispensable for businesses aiming to safeguard their systems and data integrity. Such compliance is not merely about regulatory adherence but also about fostering trust and resilience in an increasingly digital landscape.

How to Create Efficient Electrical Control Panel Designs for Optimal Performance - Ensuring Safety Standards and Compliance in Control Panels

| Design Element | Description | Safety Standard Compliance | Performance Metric |

|---|---|---|---|

| Panel Layout | Designing an organized and accessible layout for all components. | IEC 61439 | Ease of access |

| Heat Management | Incorporating ventilations and fans to manage internal heat. | NEC Article 400 | Temperature control |

| Wire Management | Using cable ties and ducts for organized wiring. | UL 508A | Reduced short circuit risks |

| Component Selection | Choosing components rated for the application’s environment. | ISO 9001 | Lifetime performance |

| Labeling | Clearly labeling all components and connections. | ANSI Z535 | Operational efficiency |

Testing and Troubleshooting Techniques for Optimal Performance

Testing and troubleshooting are critical components in ensuring optimal performance of electrical control panel designs. A systematic approach begins with visual inspections, where technicians should check for any obvious signs of wear, loose connections, or damage. Utilizing standardized testing equipment, like multimeters and oscilloscopes, can help in identifying issues such as voltage drops or signal interference. Regular testing not only aids in detecting problems early but also ensures that panels operate within their specified parameters.

In addition to regular inspections, implementing a robust troubleshooting protocol is essential. When problems arise, following a clear step-by-step methodology allows for efficient diagnostics. This may involve isolating specific circuits, testing components individually, and referencing wiring diagrams or schematics for clarity. Documenting findings during this process creates a valuable record that can inform future maintenance and reduce downtime. By prioritizing these techniques, engineers can enhance reliability and performance, ultimately leading to more efficient and effective electrical control panels.

Related Posts

-

How to Optimize Your Electrical Control Panel Design for Maximum Efficiency and Safety

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency

-

How to Master Electrical Control Panel Design for Your Next Project

-

How to Optimize Your Manufacturing Efficiency with VFD Control Panels

-

How to Optimize Your HMI Control Panel for Enhanced User Experience

-

Essential Guide to Mastering PLC Controller Programming Techniques