What Are Electrical Control Solutions and How Do They Revolutionize Automation?

In today's rapidly advancing industrial landscape, electrical control solutions have emerged as pivotal technologies driving the revolution in automation. According to a recent report by MarketsandMarkets, the global market for industrial automation is projected to reach $296.70 billion by 2026, growing at a CAGR of 9.7% from 2021 to 2026. This growth is largely fueled by the increasing demand for efficient production processes and the integration of smart technologies in manufacturing environments.

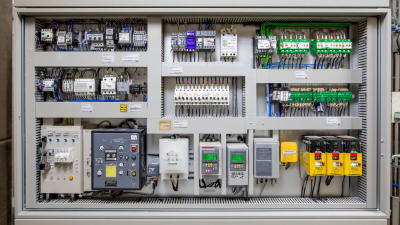

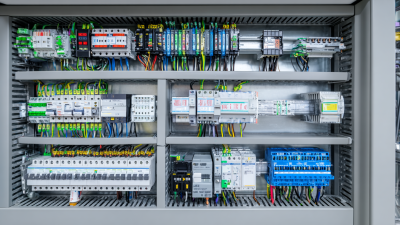

Electrical control solutions, which encompass various components such as relays, circuit breakers, and programmable logic controllers (PLCs), streamline operations, enhance safety, and improve overall productivity. With their ability to monitor and control machinery in real-time, these solutions not only reduce operational costs but also play a critical role in facilitating the transition toward Industry 4.0, where connectivity and automation become the norm. As industries continue to embrace digital transformation, the impact of electrical control solutions will be pivotal in shaping a more efficient and automated future.

Electrical control solutions, which encompass various components such as relays, circuit breakers, and programmable logic controllers (PLCs), streamline operations, enhance safety, and improve overall productivity. With their ability to monitor and control machinery in real-time, these solutions not only reduce operational costs but also play a critical role in facilitating the transition toward Industry 4.0, where connectivity and automation become the norm. As industries continue to embrace digital transformation, the impact of electrical control solutions will be pivotal in shaping a more efficient and automated future.

Understanding Electrical Control Solutions: A Deep Dive

Electrical control solutions are pivotal in modern automation, providing the framework for efficiently managing and regulating machinery and processes. They encompass a variety of technologies, including Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and Human-Machine Interfaces (HMIs). According to a report by MarketsandMarkets, the global electrical control system market is projected to reach $126.12 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth highlights the increasing reliance on these advanced control technologies in industries such as manufacturing, oil and gas, and energy management.

A deep dive into these solutions reveals their role in enhancing operational efficiency through automation. By integrating sensors, actuators, and control algorithms, companies can achieve precise monitoring and adjustments of their processes. For instance, a study from Schneider Electric indicates that implementing electrical control solutions can boost productivity by up to 30% while reducing energy consumption by as much as 25%. This efficiency not only maximizes output but also significantly minimizes operational costs, illustrating why businesses are rapidly adopting these technologies to improve their competitive edge in a market that demands continuous innovation.

Impact of Electrical Control Solutions on Automation

This bar chart illustrates the significant impact of electrical control solutions on various automation metrics, including cost reduction, efficiency improvement, error rate reduction, and speed increase. These metrics highlight how advanced electrical control technologies can transform industrial processes, leading to enhanced productivity and operational excellence.

The Role of Electrical Control Systems in Modern Automation

Electrical control systems play a pivotal role in modern automation by providing precise command and feedback mechanisms that enhance efficiency and productivity. According to a report by MarketsandMarkets, the global market for industrial automation is expected to reach $214.79 billion by 2026, driven largely by advancements in electrical control technologies. These systems integrate hardware and software components to facilitate real-time monitoring and control of industrial processes, allowing businesses to optimize operations, reduce downtime, and improve safety standards.

Electrical control systems play a pivotal role in modern automation by providing precise command and feedback mechanisms that enhance efficiency and productivity. According to a report by MarketsandMarkets, the global market for industrial automation is expected to reach $214.79 billion by 2026, driven largely by advancements in electrical control technologies. These systems integrate hardware and software components to facilitate real-time monitoring and control of industrial processes, allowing businesses to optimize operations, reduce downtime, and improve safety standards.

Moreover, the implementation of smart electrical control solutions is transforming traditional manufacturing practices. A study by McKinsey indicates that digitization in manufacturing can yield productivity improvements of up to 30%. By leveraging sensors, actuators, and programmable logic controllers (PLCs), these control systems not only increase operational agility but also enable predictive maintenance, ultimately leading to significant cost savings. As industries continue to embrace automation, the role of electrical control systems will be crucial in shaping the future of manufacturing and beyond.

Key Components of Electrical Control Solutions Explained

Electrical control solutions play a pivotal role in modern automation by integrating various components that streamline processes and enhance operational efficiency. Key components of these solutions include programmable logic controllers (PLCs), sensors, and actuators. PLCs serve as the brain of automation systems, processing inputs from sensors to control machinery and equipment effectively.

Sensors detect changes in the environment or system performance, while actuators perform physical actions based on PLC commands, such as opening a valve or moving a conveyor belt.

Sensors detect changes in the environment or system performance, while actuators perform physical actions based on PLC commands, such as opening a valve or moving a conveyor belt.

Tips: When implementing electrical control solutions, consider using sensors that are compatible with your PLCs to ensure seamless communication. Additionally, regularly updating software can prevent potential downtime and enhance system functionality.

Furthermore, integration with the Internet of Things (IoT) allows for remote monitoring and control, providing organizations the ability to analyze performance data in real-time. This advanced connectivity contributes to predictive maintenance strategies, reducing operational costs significantly.

Tips: Invest in IoT-enabled devices to leverage data analytics and improve decision-making processes. Regular staff training on new technologies will also maximize the benefits of these electrical control solutions.

Benefits of Implementing Electrical Control Systems in Industries

The implementation of electrical control systems in industries brings numerous benefits that significantly enhance operational efficiency and productivity. Firstly, these systems allow for precise control over machinery and processes, reducing the likelihood of human error. By automating repetitive tasks and streamlining workflows, industries can achieve a higher level of accuracy and consistency, leading to improved product quality and reduced waste.

Moreover, electrical control solutions facilitate real-time monitoring and data collection, empowering organizations to make informed decisions based on up-to-date information. This capability not only aids in predictive maintenance, which minimizes downtime and repair costs, but also enhances overall safety in the workplace. By integrating advanced technologies, such as sensors and IoT devices, companies can respond promptly to any anomalies, ensuring a safer and more efficient operational environment. This technological advancement is pivotal in transforming traditional manufacturing processes into smart, automated systems that drive competitiveness and innovation in the industry.

What Are Electrical Control Solutions and How Do They Revolutionize Automation?

| Dimension | Description | Benefits |

|---|---|---|

| Process Automation | Use of control systems to manage industrial processes for better efficiency. | Increased throughput and reduced operational costs. |

| Monitoring & Control | Real-time data collection and analysis to adjust operations on-the-fly. | Enhanced decision making and proactive maintenance. |

| Safety & Compliance | Systems designed to adhere to safety regulations and standards. | Reduction of risks and avoidance of penalties. |

| Energy Efficiency | Optimizing energy use in production processes. | Lower energy costs and reduced environmental impact. |

| Scalability | Ability to upgrade systems with minimal disruptions. | Future-proofing investments and adapting to market changes. |

Future Trends: How Electrical Control Solutions Will Shape Automation

The future of automation is being dramatically shaped by advancements in electrical control solutions, particularly as the Asia-Pacific region emerges as the largest market for smart manufacturing, boasting an impressive compound annual growth rate (CAGR) of 15.7% during the forecast period. This rapid growth signals a shift toward more integrated and efficient production processes driven by cutting-edge technologies. The recent AI Empowered Manufacturing Digitalization Conference held in Shanghai highlights the increasing focus on edge-driven AI, which enables real-time data analysis and machine learning applications, enhancing operational efficiency and paving the way for smarter manufacturing environments.

As industry leaders explore innovations, the global industrial automation market is projected to surge from $205.86 billion in 2022 to $395.09 billion by 2029, representing a notable CAGR of 9.8%. This significant growth underscores the critical role that electrical control solutions play in optimizing production workflows and reducing operational costs. With the advent of intelligent technologies and a commitment to sustainable practices, industries are poised to adopt more advanced automation strategies that not only improve productivity but also contribute to a greener future for manufacturing.

Related Posts

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

What is the Importance of PLC Programming in Modern Automation

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

How to Optimize HMI Control Panels for Enhanced Industrial Efficiency and Performance

-

Mastering Control Engineering 10 Essential Digital Tips for Boosting Efficiency and Reducing Costs

-

7 Best Electrical Power Distribution Panel Features to Maximize Efficiency in Your Facility