Enhancing Industrial Efficiency: The Future of PLC Control Systems in Smart Manufacturing

In the rapidly evolving landscape of smart manufacturing, the role of PLC control systems is increasingly critical to enhancing industrial efficiency. According to a report by MarketsandMarkets, the global PLC market is projected to grow from USD 8.6 billion in 2020 to USD 12.9 billion by 2025, at a CAGR of 8.6%. This growth is fueled by the increasing demand for automation and the need for real-time data analytics, underscoring the significance of advanced PLC control technologies in modern manufacturing environments. The integration of Internet of Things (IoT) capabilities with PLC systems is set to revolutionize operational workflows, enabling manufacturers to optimize performance and reduce downtime.

As industry expert John Smith, a leading consultant in automation technologies, aptly states, “The future of PLC control lies in its ability to seamlessly bridge the gap between physical processes and digital insights.” This perspective highlights the transformative potential of smart manufacturing facilitated by sophisticated PLC control systems.

Organizations are required to adapt to this paradigm by investing in robust PLC solutions that drive efficiency, agility, and competitive advantage in a market characterized by rapid technological advancements and evolving consumer demands. Embracing these innovations in PLC control will be instrumental for manufacturers aiming to thrive in the future industrial landscape.

Evolution of PLC Control Systems: From Traditional to Smart Manufacturing Solutions

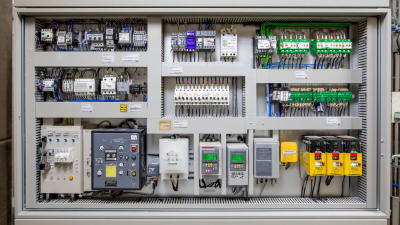

The evolution of Programmable Logic Controllers (PLCs) has revolutionized the manufacturing landscape. Traditional PLC systems played a crucial role in automating various industrial processes, providing a reliable solution for controlling machines and workflows. However, as manufacturing demands have increased, the limitations of traditional PLCs—such as limited connectivity and inflexible programming—have become apparent. This has paved the way for more advanced PLC control systems that integrate seamlessly with smart manufacturing solutions, leveraging IoT technology and data analytics for real-time decision-making.

Tips: When transitioning to smart PLC systems, ensure that your team is well-trained in new technologies, as this transition can only be successful with knowledgeable personnel. Regular training sessions can bridge the gap between traditional practices and modern needs.

Smart manufacturing solutions enhance the functionality of PLCs by enabling remote monitoring, predictive maintenance, and enhanced data collection. These advancements allow manufacturers to optimize operations, reduce downtime, and improve overall productivity. By analyzing data collected from smart PLCs, companies can gain insights into machine performance and implement streamlined processes that drive efficiency.

Tips: Start by assessing your current PLC systems to identify areas for improvement. Consider phased upgrades to incorporate smart technologies without overwhelming your production processes.

Impact of Industry 4.0 on PLC Efficiency and Operational Agility

The implementation of Industry 4.0 is significantly reshaping the landscape of PLC (Programmable Logic Controller) control systems, driving efficiency and operational agility across manufacturing sectors. As industries increasingly navigate the effects of digital transformation, recent studies indicate that smart factories equipped with advanced automation technologies can experience productivity gains of up to 30%. This shift is not only enhancing performance but also fostering a more adaptive manufacturing environment.

Technologies such as voice recognition control and generative AI are revolutionizing traditional PLCs, enabling real-time data processing and decision-making capabilities. For instance, the latest findings reveal that organizations utilizing AI-driven predictive analytics observe a 20% reduction in downtime and a marked improvement in operational responsiveness. Furthermore, the integration of containerized PLC devices has allowed manufacturers to streamline their processes, creating agility in how they respond to market demands. As companies embrace this new wave of industrial automation, they are setting a foundation for a future where operational excellence and adaptability are paramount.

Enhancing Industrial Efficiency: The Future of PLC Control Systems in Smart Manufacturing - Impact of Industry 4.0 on PLC Efficiency and Operational Agility

| Dimension | Current Value | Future Goal | Impact of Industry 4.0 |

|---|---|---|---|

| PLC Downtime (hours/year) | 250 | 100 | Reduction through predictive maintenance |

| Operational Efficiency (%) | 75 | 90 | Improved through real-time data analytics |

| Response Time (seconds) | 5 | 2 | Faster response using edge computing |

| Maintenance Costs (% of total cost) | 30 | 10 | Lower costs with IoT integration |

| System Integration Level (%) | 60 | 95 | Enhanced with cloud technologies |

Integration of IoT Technologies: Enhancing Real-Time Data Processing in PLCs

The integration of IoT technologies into PLC control systems represents a pivotal shift in the landscape of smart manufacturing. By enabling real-time data processing, IoT enhances the communication capabilities of Programmable Logic Controllers (PLCs), allowing them to collect and analyze vast amounts of data instantaneously. According to a report by MarketsandMarkets, the smart manufacturing market is projected to grow from $214 billion in 2021 to $384 billion by 2026, driven largely by advancements in IoT and data analytics. This integration facilitates predictive maintenance, reduces downtime, and optimizes production workflows, ultimately leading to increased industrial efficiency.

Tips for manufacturers looking to adopt IoT technologies include ensuring robust cybersecurity measures, as the interconnected nature of IoT can heighten vulnerability to attacks. Additionally, investing in employee training on data analytics tools is essential, enabling staff to leverage the information gathered by PLCs for informed decision-making. Companies should also consider phased implementation strategies to allow for seamless integration of new technologies without disrupting existing operations.

As industries evolve, the demand for real-time insights becomes crucial. A study by Deloitte indicates that organizations harnessing IoT data can potentially see operational cost reductions by 15-20%. By fully embracing IoT integration within their PLC systems, manufacturers can stay competitive and drive efficiency in the age of smart manufacturing.

Predictive Maintenance and PLCs: Reducing Downtime with Advanced Analytics

In the realm of smart manufacturing, the integration of predictive maintenance with PLC (Programmable Logic Controller) systems is set to revolutionize industrial efficiency. By leveraging advanced analytics, industries can significantly reduce downtime and enhance productivity. For instance, a recent analysis highlights that predictive analytics can foresee equipment failures before they occur, allowing for timely interventions that can save companies substantial amounts in repair costs and lost production time. This transition to data-driven maintenance strategies is projected to reshape factory economics across sectors, from automotive assembly lines to complex steel manufacturing plants.

Tip: To implement predictive maintenance effectively, industries should focus on enhancing the data flow between IoT devices and PLC systems. This synergy enables real-time monitoring and analysis, leading to more accurate predictions and timely maintenance actions.

The Micro and Nano PLC market is expected to witness significant growth, driven by the demand for more compact and efficient control systems. From 2025 to 2035, the segment shows promising trends, especially with advancements in AI solutions that facilitate predictive maintenance. By harnessing generative AI, companies can optimize their maintenance strategies and reduce unexpected downtimes further.

Tip: Investing in advanced analytics tools and training for staff on new technologies can greatly enhance the effectiveness of predictive maintenance programs. Adopting a culture of continuous improvement using data insights will foster a more resilient manufacturing environment.

Future Trends: The Role of AI and Machine Learning in PLC Control Systems

The integration of Artificial Intelligence (AI) and Machine Learning into PLC control systems is revolutionizing smart manufacturing, particularly through the application of digital twin technology. Digital twins enable enhanced simulation design and high-resolution modeling, drastically improving the accuracy of manufacturing processes. By leveraging real-time data and predictive analytics, manufacturers can optimize operations, reduce downtime, and improve product quality, paving the way for innovative applications in product design and system efficiency.

Moreover, the substantial advancements in brain-computer interface technology illustrate the potential for AI-driven solutions in industry. With performance enhancements reaching 216 times and energy consumption reduced by a factor of a thousand, these breakthroughs highlight the promising intersection of AI and automation. The ability to control drones and other machinery using mere thought represents a significant leap forward that not only enhances productivity but also opens new avenues for human-machine interaction in manufacturing environments. This synergy between AI and PLC systems underscores a transformative trend that will shape the future of the industrial landscape.

Enhancing Industrial Efficiency: The Future of PLC Control Systems in Smart Manufacturing

This chart illustrates the projected efficiency of PLC (Programmable Logic Controller) control systems in smart manufacturing from 2020 to 2025. As industries increasingly integrate AI and machine learning, a significant rise in efficiency is expected, reaching 90% by 2025.

Related Posts

-

What is the Importance of PLC Programming in Modern Automation

-

What Are Electrical Control Solutions and How Do They Revolutionize Automation?

-

Revolutionizing Industries with Next Generation Automation Control Panels

-

How to Master PLC Controller Programming for Industrial Automation

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

Understanding the Role of Automation Control Panels in Modern Industrial Systems