10 Essential Tips for Designing an Efficient Electrical Control Panel

In the rapidly evolving field of industrial automation, the design of an efficient electrical control panel is crucial for optimizing performance, safety, and maintainability. According to a recent report by Markets and Markets, the global market for electrical control panels is projected to reach USD 102.9 billion by 2025, growing at a CAGR of 7.2%. This growth underscores the increasing reliance on sophisticated control panels across various sectors, including manufacturing, energy, and building management systems.

An effective electrical control panel serves as the nerve center of electrical systems, enabling operators to manage equipment effectively while ensuring compliance with safety standards. Specialized guidelines provided by the National Electrical Manufacturers Association (NEMA) indicate that the design process must prioritize factors such as thermal management, component layout, and accessibility. As the demand for efficient energy management continues to rise, adopting best practices in electrical control panel design becomes indispensable for organizations aiming to enhance operational efficiency and reduce downtime.

To achieve a successful balance between functionality and safety, this article will explore ten essential tips for designing an efficient electrical control panel. These insights will not only help industry professionals improve their designs but also contribute to the overall advancement of electrical engineering practices in today's dynamic industrial landscape.

Understanding the Purpose and Importance of Electrical Control Panels

Electrical control panels serve as the nerve center for managing and monitoring electrical systems. They play a crucial role in ensuring the efficient operation of machinery, providing a centralized location for control, protection, and distribution of electrical power. The importance of these panels cannot be overstated, as they contribute to the safety, reliability, and efficiency of electrical systems in various applications, from industrial settings to commercial buildings.

Understanding the purpose of electrical control panels is essential for effective design. They are designed to facilitate operations by offering features such as circuit breakers, switches, and monitoring devices. These components not only protect against overloads and short circuits but also allow for easy troubleshooting and maintenance. By centralizing control functions, electrical control panels streamline operations, reduce downtime, and enhance overall system performance, making them an indispensable element in modern electrical engineering.

10 Essential Tips for Designing an Efficient Electrical Control Panel

| Tip Number | Tip Description | Importance | Implementation Complexity |

|---|---|---|---|

| 1 | Define the Purpose of the Control Panel | High | Low |

| 2 | Use Standardized Components | Medium | Medium |

| 3 | Create a Clear Wiring Diagram | High | Medium |

| 4 | Consider Environmental Factors | High | Medium |

| 5 | Plan for Future Expansion | Medium | High |

| 6 | Ensure Proper Ventilation | High | Medium |

| 7 | Use Quality Materials | Very High | Medium |

| 8 | Implement Safety Standards | Critical | High |

| 9 | Label Everything Clearly | High | Low |

| 10 | Regular Maintenance Checks | Very High | Medium |

Key Design Principles for Efficient Electrical Control Panels

Designing an efficient electrical control panel requires meticulous attention to detail and adherence to key principles. One of the fundamental design principles is to ensure proper organization and layout. By grouping related components together, you facilitate easier troubleshooting and maintenance. This not only enhances operational efficiency but also minimizes downtime when repairs are needed. Additionally, maintaining clear labeling of all components is crucial for immediate identification, which speeds up any necessary interventions.

Another essential aspect is thermal management. Overheating can lead to malfunctions and reduced lifespan of electronic components. Incorporating adequate ventilation and strategically placing heat-generating devices away from sensitive components can greatly improve overall panel performance. Furthermore, selecting the right materials that can withstand high temperatures will contribute to the longevity of the control panel.

Finally, consider modular design when planning your electrical control panel. Modular designs allow for easy upgrades and expansions without extensive rewiring or reconstruction. This adaptability is vital in addressing future technological needs and ensures your system remains relevant in a rapidly evolving landscape. By following these principles, you can create a control panel that not only meets current demands but is also poised for future enhancements.

Selecting Appropriate Components for Control Panel Design

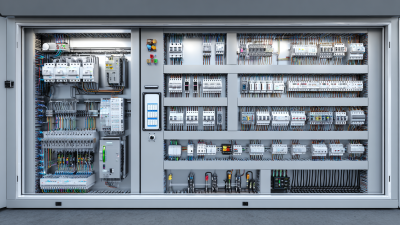

When designing an efficient electrical control panel, selecting the appropriate components is critical to the overall functionality and safety of the system. According to a report by the National Electrical Manufacturers Association (NEMA), the right selection of components can lead to a 20% increase in operational efficiency and a significant reduction in energy consumption. Key components such as circuit breakers, relays, and sensors must be meticulously chosen based on the specific application and load requirements. Understanding the ratings and specifications of these components ensures they can handle the electrical loads without overheating or failing.

Furthermore, the integration of digital monitoring devices and advanced control systems has transformed traditional control panel design. A 2022 survey by the International Society of Automation highlighted that 65% of companies prioritizing smart components in their control panel designs reported improved maintenance efficiency and reduced downtime. By opting for smart relays and programmable logic controllers (PLCs) that offer real-time diagnostics, engineers can enhance the reliability and adaptability of control panels. Consequently, an informed selection of components directly correlates with operational success and long-term sustainability in industrial applications.

Implementing Safety Standards and Compliance in Control Panel Design

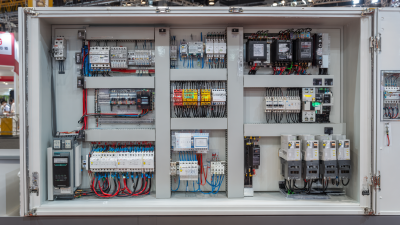

When designing an electrical control panel, implementing safety standards and compliance is paramount. Adhering to relevant regulations, such as ANSI, IEC, and UL standards, ensures not only the safety of users but also enhances the reliability of the system. Proper adherence to these standards can significantly reduce the risk of electrical hazards and equipment failures.

One essential tip is to ensure that all components used within the panel are certified and rated for the intended application. This includes circuit breakers, relays, and terminals. Another crucial aspect involves the layout of the panel. Design it to allow for adequate airflow and heat dissipation, as overheating can lead to malfunctions or catastrophic failures. Additionally, employing clear labeling and organized wiring can prevent accidental disconnections or unsafe conditions during maintenance.

Moreover, consider implementing emergency stops and circuit isolation features within your design. These not only provide a vital fail-safe in case of an emergency but also ensure compliance with safety regulations. Regular inspections and testing of the panel after installation are critical to identify and rectify any potential safety issues, thus maintaining a secure working environment.

Efficiency of Electrical Control Panel Designs

This chart illustrates the efficiency ratings of various electrical control panel designs based on different factors such as safety compliance, energy efficiency, and ease of maintenance. The data reflects an analysis of industry standards and best practices for designing electrical control panels.

Tips for Organizing Layout and Wiring in Electrical Control Panels

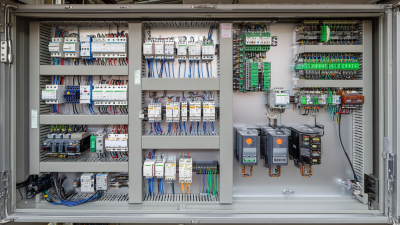

When designing an efficient electrical control panel, organizing the layout and wiring is paramount for functionality and safety. Firstly, consider a systematic approach to component placement. Components should be arranged in a logical sequence, with inputs on one side and outputs on the other. This layout minimizes the distance that signals must traverse and streamlines the workflow.

Additionally, using modular enclosures can enhance accessibility, allowing for easier modifications or replacements in the future.

Wiring is another critical aspect in achieving an efficient control panel design. Careful planning of wire paths reduces clutter and potential signal interference. Opt for color-coded and labeled wires to ensure easy identification during installation and maintenance. The use of cable ties and wire ducts helps maintain order and reduces the risk of damage from moving parts. Proper grounding and the use of surge protection devices can further increase the reliability and longevity of the panel, ensuring that it operates without disruption. By prioritizing layout and wiring organization, designers can create a control panel that is both efficient and user-friendly.

Related Posts

-

How to Optimize Your Electrical Control Panel Design for Maximum Efficiency and Safety

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency

-

How to Optimize Your Manufacturing Efficiency with VFD Control Panels

-

How to Create Efficient Electrical Control Panel Designs for Optimal Performance

-

What Are Electrical Control Solutions and How Do They Revolutionize Automation?

-

Innovative Trends in Electrical Control Panel Design at the 138th Canton Fair 2025 in China