10 Essential Tips for Panel PLC Programming Success

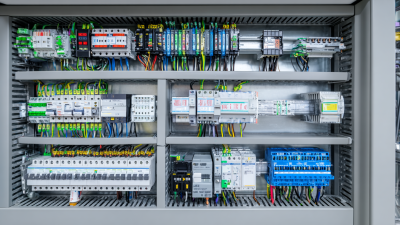

Panel PLC programming is crucial for modern industrial automation. According to a recent report by the International Society of Automation, over 60% of manufacturing processes now rely on PLC systems. These programmable logic controllers enhance efficiency and reliability in various applications. However, successful panel PLC programming demands expertise and attention to detail.

Expert John Smith, a seasoned PLC programmer with over 20 years of experience, emphasizes the importance of foundational knowledge: “Understanding the basics of panel PLC programming is key to achieving success.” This insight reflects a common oversight in the industry. Many practitioners focus on advanced programming techniques, neglecting essential principles. This often leads to flawed implementations and costly downtime.

A recent study highlighted that nearly 30% of PLC installations encounter issues due to poor programming practices. This statistic stresses the need for a structured approach in panel PLC programming. Attention to detail can make the difference between seamless operation and unexpected failures. As the industry evolves, integrating effective programming strategies becomes more important than ever.

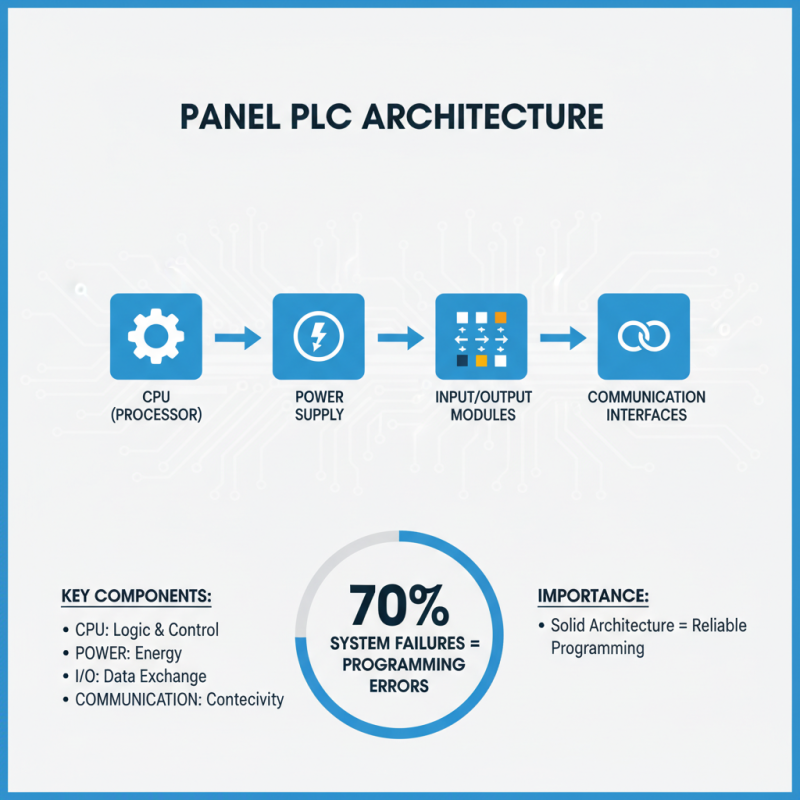

Understanding Panel PLC Architecture and Its Importance in Programming

Understanding the architecture of Panel PLCs is crucial for successful programming. Panel PLCs consist of several components: the CPU, power supply, input/output modules, and communication interfaces. Each piece plays a role in ensuring seamless operation. According to industry reports, over 70% of system failures can be traced back to programming errors, highlighting the importance of a solid understanding of architecture.

For effective programming, it’s vital to keep readability in mind. Organize code effectively. Use comments generously. A clean layout enhances troubleshooting. Tip: Break complex logic into smaller, manageable blocks. This will make your program easier to follow. Complex code often leads to confusion and mistakes.

It’s also important to keep in mind the limitations of your hardware. Not all Panel PLCs support advanced functions. This can lead to frustration. Tip: Always check the specifications before implementation. Adapting to hardware constraints can lead to more stable programs. A deeper dive into architecture will always pay off. Embrace the learning curve and adjust your approach accordingly.

Key Programming Languages for Panel PLCs: A Comparative Analysis

When it comes to panel PLC programming, choosing the right programming language is crucial. Different languages cater to different needs. Ladder Logic is widely used. It resembles electrical relay logic, making it easy for electricians. However, it can be limiting for complex tasks. Function Block Diagram (FBD) provides more flexibility. It allows visual representation of functions. But, it might not be intuitive for newcomers.

Structured Text (ST) offers a textual approach. It's powerful for complex calculations. Yet, it can overwhelm beginners who may not be comfortable with coding. Instruction List (IL) is another option. It’s compact, but not user-friendly. Many find it outdated compared to modern standards. Each language has its strengths and weaknesses. Selecting one often depends on the application and the programmer's expertise.

Moreover, real-world scenarios can challenge these languages. A simple task can become complicated. Misinterpreting a language’s syntax could lead to errors. Debugging may require more time than expected. Adapting to a chosen language is essential. Continuous learning is key in this field. Embrace the complexity and learn from the challenges.

Panel PLC Programming Languages Usage Comparison

Best Practices for Debugging and Testing Panel PLC Applications

Debugging and testing panel PLC applications can often feel overwhelming. According to recent industry reports, nearly 70% of engineers cited debugging as the most time-consuming aspect of their projects. These statistics highlight the critical need for effective practices. Understanding the root causes of issues early can save time and resources.

One essential practice is to adopt systematic testing protocols. Regularly conducting unit tests can help catch errors before they escalate. Engineers recommend documenting every test case. This approach not only enhances clarity but also allows for better reflection on past mistakes. Identifying patterns in recurring errors can refine future programming efforts.

Another common struggle is managing communication among team members. Poor communication can lead to misunderstandings, which result in debugging delays. A 2021 survey indicated that communication issues lead to a 25% increase in project timelines. Regular team check-ins and open discussions can significantly reduce these delays. Encouraging a culture where team members feel comfortable sharing failures can lead to valuable insights.

Integrating Safety Protocols in Panel PLC Programming for Enhanced Reliability

Incorporating safety protocols in panel PLC programming is vital for ensuring reliability. According to industry reports, nearly 70% of machinery failures stem from programming errors and oversight. This statistic emphasizes the need for comprehensive safety measures. When programmers overlook safety, they put the entire system at risk. Designing with safety in mind protects not only the machinery but also the operators.

Implementing standard safety practices can drastically reduce these risks. Regularly updating safety protocols is crucial. Data indicates that companies that adopt rigorous safety measures see a 50% reduction in accidents. However, many organizations still treat these protocols as afterthoughts. This negligence often leads to costly downtime. Programmers must approach safety with a proactive mindset rather than a reactive one.

Real-time monitoring systems serve as an effective safety enhancement. They provide immediate alerts when deviations occur. This allows for quick responses to potential failures. Additionally, integrating user training with safety standards is often overlooked. When operators lack knowledge, it increases the likelihood of accidents. Taking these factors seriously can enhance reliability and ultimately improve productivity.

10 Essential Tips for Panel PLC Programming Success - Integrating Safety Protocols in Panel PLC Programming for Enhanced Reliability

| Tip Number | Tip Description | Safety Protocols | Expected Outcome |

|---|---|---|---|

| 1 | Understand the PLC architecture thoroughly. | Follow manufacturer safety guidelines. | Improved troubleshooting efficiency. |

| 2 | Use standardized programming languages (e.g., Ladder Logic). | Ensure consistent application of safety measures. | Higher code comprehension among team members. |

| 3 | Implement version control for code management. | Maintain documentation of safety checks. | Better tracking of changes and enhanced accountability. |

| 4 | Incorporate modular programming practices. | Define clear safety boundaries for modules. | Easier updates and modifications without risks. |

| 5 | Test code in simulation before going live. | Use simulated safety triggers. | Identify potential issues prior to deployment. |

| 6 | Document code thoroughly for future references. | Include safety rationale in documentation. | Facilitate smooth handover and training. |

| 7 | Train the team on safe programming practices. | Conduct regular safety audits. | Reduce programming errors related to safety. |

| 8 | Utilize error handling to manage unexpected events. | Integrate safety shutdown procedures. | Minimize risks during fault conditions. |

| 9 | Regularly update software and firmware. | Review safety patch updates. | Enhanced system security and reliability. |

| 10 | Conduct thorough post-mortem reviews after incidents. | Document lessons learned regarding safety. | Continuous improvement in safety protocols. |

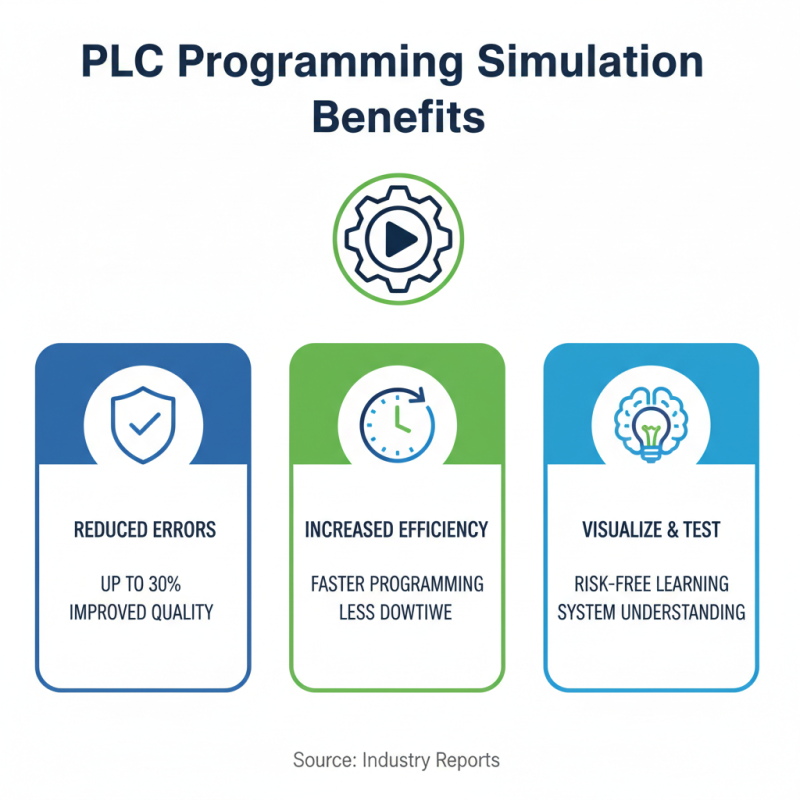

Utilizing Simulation Tools for Effective Panel PLC Programming and Troubleshooting

When it comes to panel PLC programming, simulation tools can significantly enhance both programming and troubleshooting efforts. According to industry reports, using simulation tools can reduce errors by up to 30%. This reduction translates into improved efficiency and lower downtime during programming. Simulations allow engineers to visualize the system and test logic without risking real hardware.

One tip for success is to always validate your logic through simulation. Before deploying any code, run simulations to identify potential issues. This proactive approach minimizes costly mistakes. Another crucial tip is to regularly update your simulation environment with new data. Keeping simulations current improves accuracy and reflects real-world operations.

While simulations are beneficial, they are not flawless. Some errors may still occur during real-world application. For instance, unexpected interactions between components might not be apparent in a simulated environment. This reality highlights the importance of combining simulation with thorough on-site testing. Being aware of these limitations ensures a more robust programming strategy.

Related Posts

-

What is HMI Programming and How to Get Started with It

-

How to Optimize Control Systems for Improved Efficiency and Performance

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

2025 How to Master Control Systems Engineering for Optimal Performance

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

How to Optimize Manufacturing Control Systems for Increased Efficiency and Productivity