Exploring the Evolution of Control Panels: Industry Insights and Future Trends in Automation Technology

The landscape of automation technology has undergone significant transformation over the years, particularly in the realm of control panels, which serve as the nerve centers for various industrial processes.

According to the MarketsandMarkets report, the global control panel market is projected to reach approximately $50 billion by 2025, reflecting a compound annual growth rate (CAGR) of about 6.5% from 2020. This growth is fueled by the increasing demand for efficient energy management and the integration of advanced technologies such as IoT and AI.

As industries strive for greater reliability and enhanced operational efficiency, the role of control panels evolves from simple monitoring tools to sophisticated interfaces that enable real-time decision-making and predictive maintenance. This article delves into the evolution of control panels, examining how technological advancements and industry trends are reshaping their development and deployment in the automation sector.

The Historical Development of Control Panels in Automation Technology

The historical development of control panels in automation technology reflects a significant evolution influenced by advancements in industrial processes and the advent of digital technologies. In the early days, control panels were primarily mechanical devices, relying upon switches and gauges to handle industrial equipment. However, by the 1980s, with the introduction of programmable logic controllers (PLCs) and microprocessors, the complexity and functionality of control panels dramatically increased. According to a report by MarketsandMarkets, the global industrial automation market is projected to grow from $175 billion in 2020 to $296 billion by 2025, showcasing the critical role that evolving control panel technology plays in this sector.

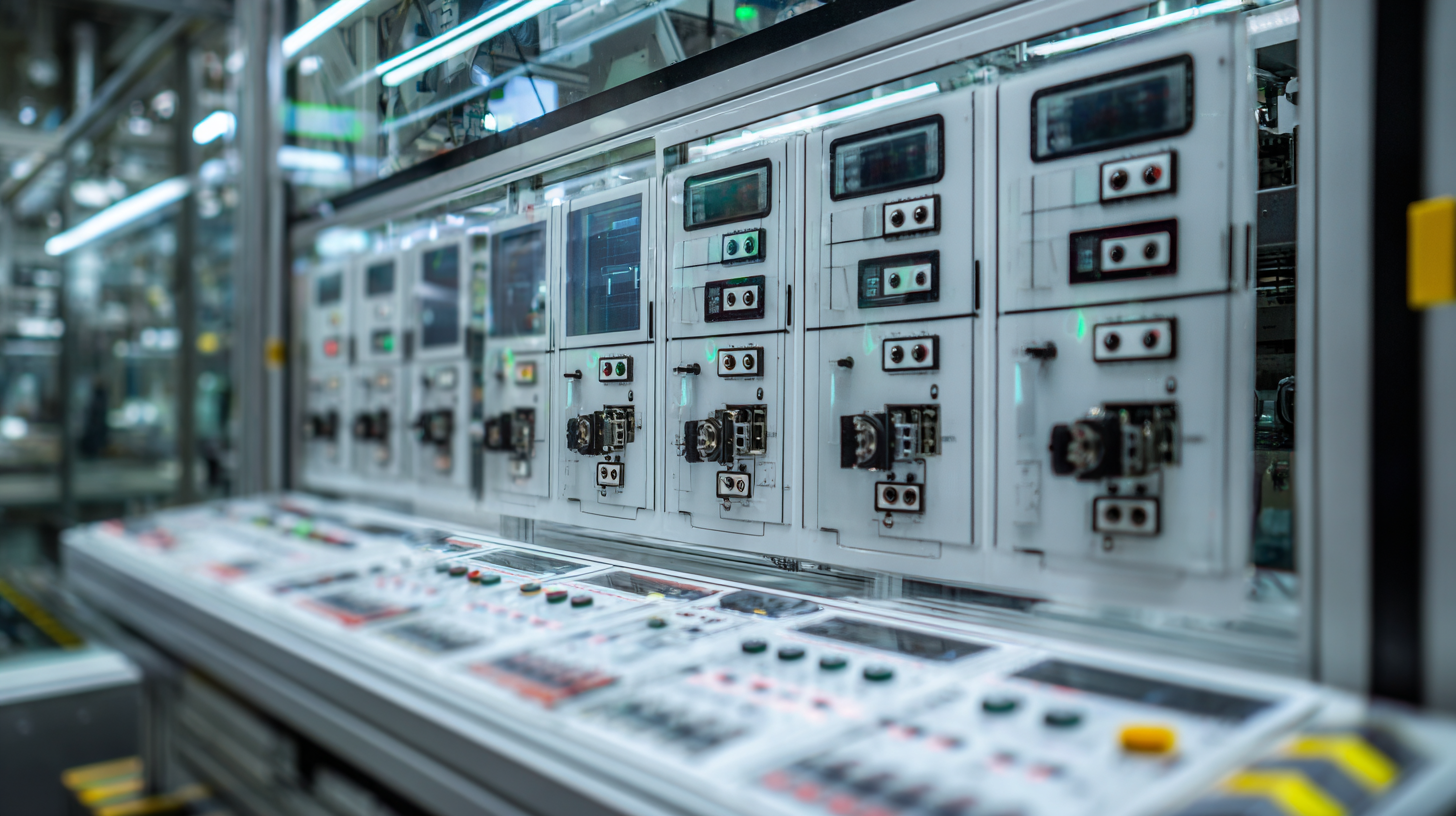

Over time, the integration of touchscreen interfaces and advanced software has transformed control panels into sophisticated command centers capable of real-time data analysis and remote monitoring. A study by ResearchAndMarkets indicates that the global human-machine interface (HMI) market, which includes advanced control panels, is expected to reach approximately $8 billion by 2026. This shift not only enhances operational efficiency but also improves user experience, as operators can derive insights and manage systems more intuitively. As industries continue to embrace automation, the future of control panels is set to prioritize connectivity, interoperability, and enhanced user interfaces, driving continued growth and innovation in the field.

Key Components and Their Roles in Modern Automation Systems

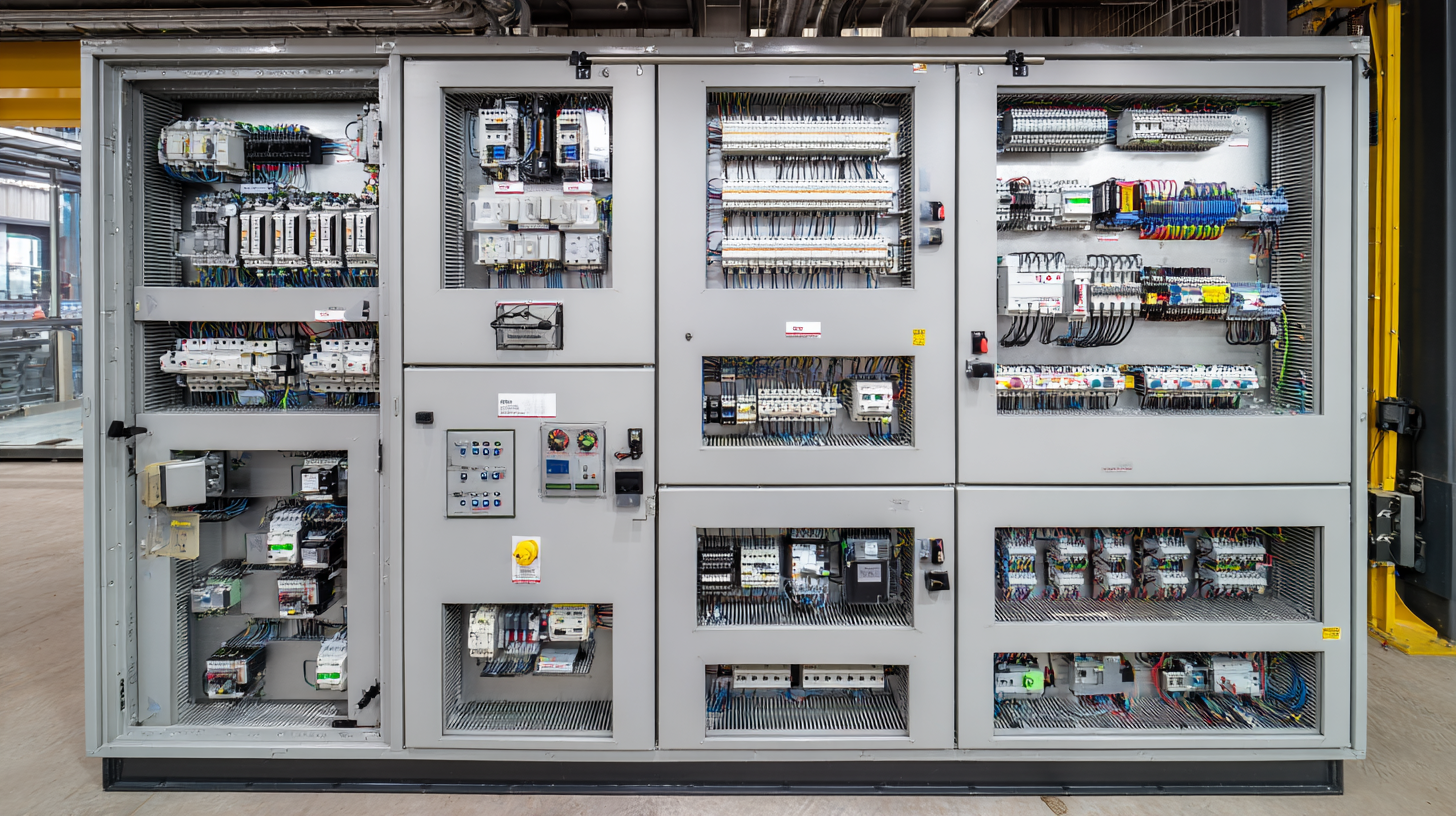

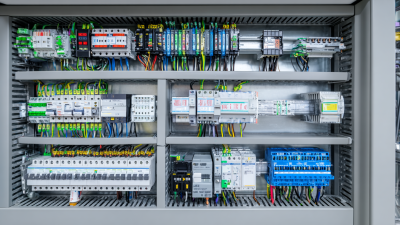

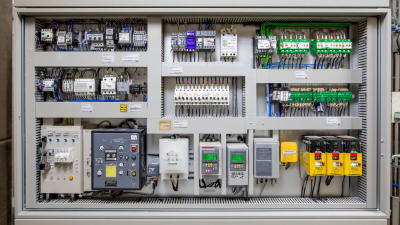

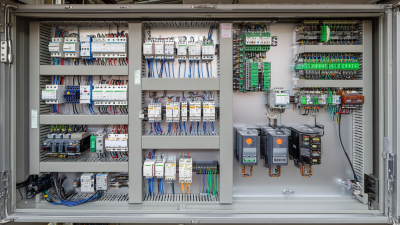

Control panels serve as the central nervous system of modern automation systems, playing a crucial role in the management and operation of various industrial processes. Key components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and I/O modules are instrumental in ensuring seamless communication between machines and operators. PLCs act as the brain, executing pre-set commands and processing input signals to control machinery effectively. Meanwhile, HMIs provide operators with a user-friendly interface, allowing for efficient monitoring and adjustments in real-time.

In addition, safety relays and contactors are essential components that provide additional layers of protection within automation systems. Safety relays are designed to detect faults and implement emergency stop functions, ensuring worker safety and equipment integrity. Contactors manage the electrical supply to various devices, enabling operators to control large machinery with minimal effort. The integration of these components not only enhances operational efficiency but also paves the way for future advancements in automation technology, such as increased connectivity and smart manufacturing solutions. As industries evolve, the role of each component within the control panel will continue to be pivotal in driving innovation and improving productivity.

Exploring the Evolution of Control Panels in Automation Technology

Challenges in Control Panel Design: Balancing Efficiency and Usability

The design of control panels plays a pivotal role in the effectiveness of automation technology. As industries increasingly rely on complex systems, the challenge lies in creating panels that not only deliver high efficiency but also ensure usability for operators. Balancing these two elements requires a deep understanding of both technical requirements and human factors. Designers must consider aspects such as the layout of controls, the intuitiveness of interfaces, and the ergonomics of operation to enhance user experience while minimizing errors.

Moreover, advancements in technology add another layer of complexity to control panel design. As automation evolves, incorporating smart technologies and data analytics into control panels can significantly improve operational efficiency. However, developers face the challenge of integrating these sophisticated features without overwhelming users. Lightweight, user-friendly interfaces that present critical information clearly can help bridge this gap, ultimately leading to a safer and more productive work environment. This pursuit of an optimal balance will define the future of control panel design as industries continue to innovate in automation technology.

Emerging Trends: Smart Control Panels and the Role of IoT

As the demand for more efficient and intelligent building management systems grows, smart control panels are emerging as a vital component in the evolution of automation technology. These systems, which integrate Internet of Things (IoT) functionalities, allow facility managers to monitor and control various aspects of building operations, from energy consumption to security systems. According to recent reports, smart building technologies can reduce energy costs by up to 30%, highlighting their strong impact on operational efficiency.

Tips: To maximize the potential of smart control panels, facility managers should prioritize the integration of IoT devices that offer real-time data analytics. This will enable proactive decision-making and enhance energy management. Additionally, investing in robust cybersecurity measures is crucial, as increasing connectivity presents potential vulnerabilities in system architecture.

The future trajectory of IoT in facility management promises even more transformative effects. Innovations such as AI-powered predictive maintenance and advanced surveillance systems are set to redefine security and upkeep strategies. Moreover, reports indicate that by 2025, the market for smart building technology will surpass $100 billion, reflecting the significant investment in these emerging trends. Companies that adapt to this shift will not only optimize their operations but also achieve a sustainable competitive edge in the industry.

Exploring the Evolution of Control Panels: Industry Insights and Future Trends in Automation Technology

| Dimension | Current Trends | Future Predictions |

|---|---|---|

| Integration with IoT | Increasing connectivity with smart devices | Widespread adoption in home and industrial settings |

| User Interface Design | Focus on user-friendly and intuitive interfaces | Enhanced immersive experiences with AR/VR integration |

| Data Analytics | Utilizing real-time data for operational decisions | Predictive analytics for maintenance and optimization |

| Cybersecurity Measures | Increasing focus on securing control systems | Integration of AI for threat detection and response |

| Sustainability Practices | Adoption of energy-efficient technologies | Further reduction of carbon footprint through automation |

Future Prospects: The Integration of AI in Automation Control Panels

As automation technology evolves, the integration of

artificial intelligence (AI)

into control panels represents a significant shift that promises to enhance efficiency and precision.

According to a report by MarketsandMarkets, the global market for AI in the automation sector is projected

to reach $14.7 billion

by 2028, growing at a compound annual growth rate (CAGR) of 26.4%.

This rapid expansion underscores the increasing reliance on AI to optimize operational processes, streamline

decision-making, and reduce operational costs.

Tips: When considering AI integration in your control systems, ensure that you evaluate your current

infrastructure and identify areas where AI could provide immediate benefits. Collaborating with AI-savvy

vendors can also facilitate a smoother transition into advanced automation.

The future landscape of automation control panels will likely see AI playing a critical role in

predictive maintenance,

anomaly detection, and

enhanced user interfaces. A study by McKinsey & Company emphasizes

that businesses implementing AI-driven insights can reduce downtime by up to

50%. By utilizing machine learning algorithms, control

panels can analyze vast amounts of data in real time, allowing for quicker responses to operational issues

and ultimately leading to improved productivity and reliability.

Tips: Regular training for your team on AI technologies will empower them to maximize the benefits of

these innovations. Additionally, engaging with industry experts can help you stay ahead of the curve

and understand emerging trends in automation technology.

Related Posts

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency

-

How to Master Electrical Control Panel Design for Your Next Project

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

How to Optimize Your Electrical Control Panel Design for Maximum Efficiency and Safety