Innovative Uses of HMI Panels in Modern Industrial Automation

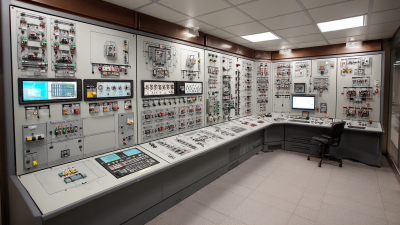

In the rapidly evolving landscape of modern industrial automation, HMI panels play a crucial role in bridging the gap between complex machinery and user-friendly interfaces. These innovative devices not only enhance operational efficiency but also empower operators with real-time data visualization and control. As industries increasingly lean towards digitization, the integration of HMI panels facilitates smarter decision-making and streamlined processes.

This article delves into various innovative applications of HMI panels, highlighting their versatility in improving productivity, ensuring safety, and enhancing user experience across diverse sectors. By exploring these transformative uses, we will uncover how HMI panels are not merely tools, but rather vital components driving the future of industrial automation.

Advantages of Advanced HMI Panel Features in Smart Factories

In today's smart factories, advanced HMI panel features play a pivotal role in enhancing operational efficiency and resilience. Modern HMI technology has evolved into a strategic asset, allowing industries to address critical challenges like machine-level operator control and monitoring seamlessly. According to industry reports, implementing advanced HMI solutions can reduce operational downtime by up to 30%, thereby significantly increasing productivity. With capabilities that range from basic panels to complex SCADA applications for multi-user systems, these panels provide operators with real-time data and analytics, enabling them to make informed decisions swiftly.

Tips: When selecting an HMI panel for your operation, consider the integration capabilities with existing systems. Opting for panels with extensive interoperability can streamline the addition of new technologies and improve overall system performance. Additionally, engaging in regular training for your operators on the latest HMI features can maximize the benefits derived from these advanced tools.

Moreover, the rise of Industry 4.0 demands that manufacturers invest in intuitive and user-friendly HMI interfaces, which are critical for optimizing workflows and enhancing operator interaction. Studies indicate that improved HMI usability can lead to a 20% increase in employee productivity. By leveraging these pioneering features, factories can not only maintain competitiveness in rapidly evolving markets but also foster a culture of continuous improvement and innovation.

Integrating IoT Technology with HMI Panels for Enhanced Automation

The integration of IoT technology with HMI panels has revolutionized modern industrial automation, driving efficiency and productivity across various sectors. According to a report by MarketsandMarkets, the global IoT in manufacturing market is expected to reach $153 billion by 2023, reflecting the growing emphasis on smart manufacturing practices. HMI panels serve as the critical interface between operators and machinery, allowing real-time data visualization and control. By incorporating IoT, these panels can connect seamlessly to cloud platforms, enabling remote monitoring and predictive maintenance, which reduces downtime and operational costs.

Tips: When selecting an HMI panel for IoT integration, consider choosing models that support open protocols such as MQTT or OPC UA. These standards ensure compatibility with a wide range of devices and platforms, enhancing your automation system's flexibility.

Additionally, IoT-enabled HMI panels can facilitate advanced analytics, improving decision-making processes. A study by Deloitte highlights that manufacturers using data analytics achieve 10% to 15% increases in productivity. By harnessing real-time data from IoT sensors, operators can make informed adjustments and optimize production lines, ensuring that companies remain competitive in an increasingly automated world.

Tips: Ensure that your HMI panel has robust cybersecurity measures in place, as the connectivity required for IoT can expose systems to potential threats. Regular updates and validation of data protocols are crucial in protecting sensitive operational information.

User-Centric Design: Customizing HMI Interfaces for Operators' Needs

In the realm of modern industrial automation, the design of Human-Machine Interface (HMI) panels has evolved significantly to prioritize user-centricity. Customizing HMI interfaces to cater to operators' needs is not only a trend but a necessity in enhancing efficiency and user satisfaction. By focusing on the specific tasks and environments in which operators work, companies can create interfaces that minimize cognitive load and streamline operations. This involves understanding the workflows, preferences, and challenges faced by operators to ensure that information is presented clearly and intuitively.

Furthermore, the integration of adaptable features within HMI panels allows operators to personalize their experience. For instance, operators can adjust display layouts, choose preferred color schemes, and configure alarm settings to suit their unique working conditions. This level of customization fosters a proactive approach to operator engagement, increasing response times and reducing errors. As a result, user-centric HMI design not only enhances individual productivity but also contributes to overall system reliability and safety within industrial settings.

Innovative Uses of HMI Panels in Modern Industrial Automation

| Use Case | Industry | Key Features | Operator Benefits | Customization Options |

|---|---|---|---|---|

| Real-time Data Monitoring | Manufacturing | Live data feeds, Alerts | Improved response time to issues | Dashboard layout, Color schemes |

| Remote Control Interfaces | Oil and Gas | Secure access, Positioning tracking | Enhanced control from various locations | Control panel layouts, Functionality extensions |

| Touchscreen Feedback Systems | Food Processing | Intuitive gestures, Tactile responses | Reduced training time, User satisfaction | Button placement, Gesture settings |

| Analytics and Reporting Tools | Logistics | Data visualization, Performance metrics | Data-driven insights for better decisions | Report formats, Graphical outputs |

| Integration with IoT Devices | Smart Manufacturing | Device compatibility, Cloud connectivity | Seamless operation of multiple devices | Device integration settings, User preferences |

Real-Time Data Visualization: Transforming Decision-Making Processes

The integration of Human-Machine Interface (HMI) panels in modern industrial automation has revolutionized the way data is visualized and interpreted in real-time. These advanced interfaces provide operators with an intuitive means to monitor complex processes, allowing for immediate access to crucial information. By consolidating various metrics into a user-friendly display, HMI panels facilitate quick recognition of operational trends and anomalies, empowering decision-makers to act swiftly in response to challenges.

Real-time data visualization enhances situational awareness, driving more informed decision-making. As industries increasingly rely on data-driven strategies, the ability to view real-time updates empowers teams to adjust settings, optimize workflows, and maintain equipment efficiency on-the-fly. By leveraging visual tools such as graphs, dashboards, and alerts, HMI panels not only streamline operations but also foster a proactive culture where continuous improvement is possible. In this context, the role of HMI panels transcends basic monitoring; they become integral to developing agile responses to dynamic industrial environments.

Innovative Uses of HMI Panels in Modern Industrial Automation

Real-Time Data Visualization: Transforming Decision-Making Processes

This chart illustrates the impact of real-time data visualization on decision-making efficiency in modern industrial environments. The data represents the average time taken in seconds to make a decision based on real-time data from HMI panels over six months.

Case Studies: Successful Implementations of HMI Panels in Industry

HMI panels have become integral to modern industrial automation, facilitating seamless interaction between operators and machines. A notable case study involves a leading automotive manufacturer that implemented HMI panels to optimize their assembly lines. By integrating advanced touch screens with real-time monitoring, operators gained immediate insights into production metrics, leading to a 30% increase in efficiency. The user-friendly interface allowed for quick adjustments, which minimized downtime and significantly improved overall workflow stability.

Another compelling example is found in the beverage industry, where a large-scale bottling plant adopted HMI technology to enhance quality control processes. With these innovative panels, operators were able to remotely monitor multiple production lines, enabling them to identify and rectify variables that could compromise product quality. As a result, the facility reported a remarkable reduction in waste and a 20% improvement in product consistency.

Tips: When integrating HMI panels, ensure that employee training is prioritized to maximize the benefits of the new technology. Regular updates to the interface can also help maintain user engagement and adaptability. Finally, consider feedback loops where operators can share their experiences and suggestions to refine the HMI system continually.

Related Posts

-

The Future of HMI Panel Innovation and Automation

-

How to Optimize HMI Control Panels for Enhanced Industrial Efficiency and Performance

-

5 Automation Panels Innovations You Didn't Know You Needed for Optimal Efficiency

-

5 Essential Tips for Optimizing Your Pneumatic Control Panel Efficiency

-

7 Essential Tips for Creating the Best Control Panel Drawings in Industrial Automation

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency