How to Master Control Engineering Techniques for Effective System Management

In today's rapidly evolving technological landscape, effective system management has become paramount across various industries, and control engineering plays a pivotal role in this domain. According to a report by the International Society of Automation, approximately 70% of organizations that implement advanced control engineering techniques report significant improvements in operational efficiency and resource allocation. This correlation underscores the necessity for professionals to master control engineering principles to optimize system performance and achieve strategic goals.

Control engineering encompasses a diverse array of techniques and methodologies designed to regulate systems and processes, ensuring stability and reliability. As industries continue to integrate automation and smart technologies, the demand for skilled control engineers is expected to grow substantially. The Bureau of Labor Statistics indicates that employment opportunities in this field are projected to increase by 10% over the next decade, reflecting the critical role control engineering plays in enhancing productivity and innovation.

To navigate this dynamic environment, mastering control engineering techniques is not just beneficial but essential for effective system management. By leveraging these techniques, organizations can enhance their capacity for data-driven decision-making, improve system responsiveness, and foster a culture of continuous improvement. Understanding and implementing these practices will ultimately equip professionals to meet the challenges of modern industrial processes while driving sustainable growth and operational excellence.

Understanding the Fundamentals of Control Engineering Techniques

Control engineering is a foundational discipline that plays a crucial role in managing complex systems across industries, from manufacturing to aerospace. At the heart of control engineering techniques is the understanding of dynamic systems, which are influenced by time-dependent variables and require precise manipulation to achieve desired outcomes. According to a recent industry report by the International Society of Automation (ISA), efficient control systems can reduce operational costs by up to 30% while improving overall system reliability and safety. This illustrates the importance of mastering control techniques to enhance productivity and system performance.

Fundamentals such as feedback loops, stability analysis, and controller design are integral to developing effective control strategies. Feedback loops allow systems to self-correct by using real-time data to adjust operations, thereby minimizing deviations from desired performance. Stability analysis, as highlighted by the IEEE Control Systems Society, ensures that systems can withstand perturbations without significant fluctuations. Furthermore, advancements in digital control technology have transformed the way systems are automated, making it essential for engineers to stay informed about the latest methodologies and tools. By grasping these core principles, engineers can drive innovation and efficiency within their organizations, leading to a more automated and responsive operational environment.

How to Master Control Engineering Techniques for Effective System Management

| Technique | Application | Effectiveness | Complexity Level |

|---|---|---|---|

| PID Control | Temperature Control Systems | High | Medium |

| Fuzzy Logic Control | Robotics | Medium | High |

| Model Predictive Control | Chemical Processing | Very High | Very High |

| Sliding Mode Control | Automotive Systems | High | Medium |

| State Space Control | Aerospace Engineering | High | High |

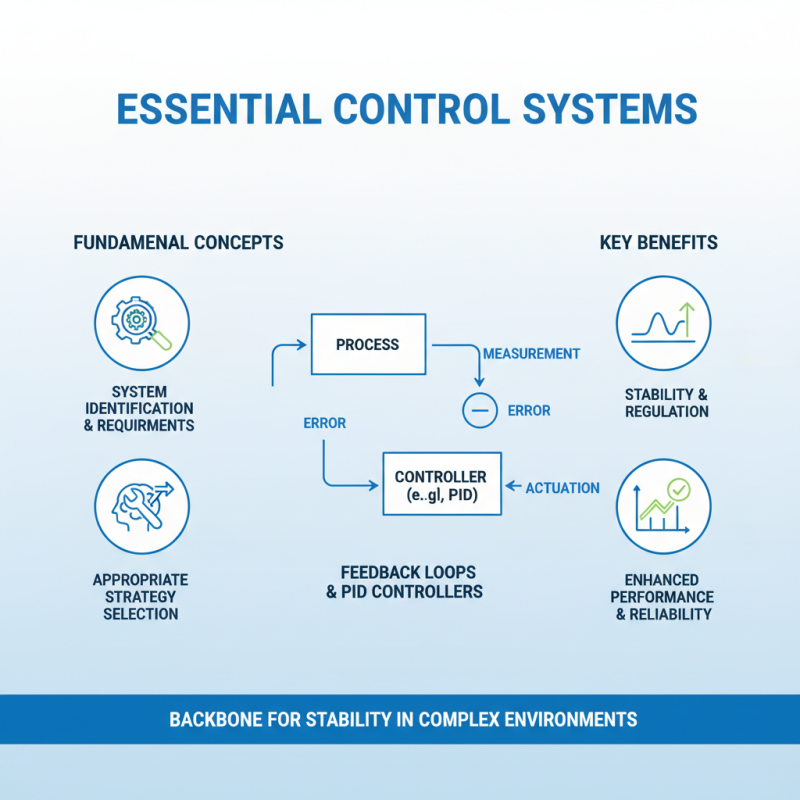

Identifying Key Control Systems Required for Effective Management

In the realm of control engineering, the identification of key control systems is fundamental for effective management. A thorough understanding of the specific requirements of a system allows engineers to choose the proper control strategies that enhance performance and reliability. Essential control systems, such as feedback loops and proportional-integral-derivative (PID) controllers, serve as the backbone for maintaining stability in complex environments. These systems play a crucial role in regulating fluctuations that can disrupt process efficiency, leading to improved outcomes in various applications, from industrial automation to environmental monitoring.

Additionally, integrating real-time data analysis into control systems can significantly bolster managerial efficacy. By harnessing advanced algorithms and machine learning techniques, managers can dynamically adapt control parameters based on current system performance. This responsiveness not only minimizes downtime but also optimizes resource allocation, promoting sustainable practices. Understanding the interplay between various control mechanisms and their impact on system behavior becomes vital for effective decision-making, ensuring that organizations can navigate challenges in an increasingly complex technological landscape.

Implementing Advanced Control Strategies in Real-World Applications

In modern engineering, the implementation of advanced control strategies has become paramount for enhancing system performance and reliability. According to a report by the International Society of Automation, organizations that adopt advanced control methodologies can achieve operational efficiencies of up to 25%. These strategies facilitate the optimization of complex systems by allowing for real-time data processing, which is essential in industries such as manufacturing, energy, and transportation. For instance, model predictive control (MPC) is increasingly employed to manage dynamic systems, providing better handling of constraints and reducing operational costs.

Moreover, the integration of artificial intelligence with control engineering techniques is reshaping how systems are managed in real-world applications. A study published by the Institute of Electrical and Electronics Engineers points out that AI-driven control systems can improve decision-making processes, leading to reduced downtime and increased productivity. In sectors like petrochemicals and utilities, predictive analytics and machine learning algorithms are being leveraged to forecast system variations, enabling preemptive adjustments that enhance overall operational stability. As industries innovate and adopt these advanced control strategies, the potential for increased efficiency and reduced waste becomes increasingly evident.

Evaluating System Performance and Stability in Control Engineering

Evaluating system performance and stability in control engineering is crucial for effective system management. To achieve this, engineers typically rely on mathematical models and simulation techniques that allow for the prediction and analysis of system behavior under various conditions. Key performance metrics often include response time, accuracy, and robustness against disturbances. By closely monitoring these metrics, engineers can ensure that systems perform optimally and meet specified requirements.

Tips: Regularly conducting stability analyses using tools such as Bode plots and root locus techniques can help in identifying potential issues before they escalate. Additionally, employing software simulations during the design phase can illuminate how a system will respond to different inputs and conditions, providing invaluable insights that guide adjustments.

In assessing system performance, it's important to incorporate real-time data and feedback loops. Utilizing sensors that provide real-time information on system behavior allows for continuous monitoring and quick adjustments. This not only enhances stability but also improves overall system efficiency.

Tips: Implementing a PID control strategy can effectively manage system responses. Make sure to continuously tune the PID parameters based on the feedback received to maintain optimal performance and stability throughout the system’s lifecycle.

Optimizing Control Engineering Techniques for Continuous Improvement

Optimizing control engineering techniques is essential for fostering continuous improvement across engineering systems. At the heart of this optimization lies the careful analysis of system performance, which requires a deep understanding of dynamic behaviors and control strategies. By employing methodologies such as model predictive control and adaptive control, engineers can enhance system responsiveness and stability, addressing inefficiencies and maximizing productivity.

In order to achieve meaningful advancements, it is crucial to implement a feedback loop that not only monitors system output but also informs adjustments in real time. Utilizing data analytics and artificial intelligence tools can significantly aid in identifying patterns and forecasting potential issues before they escalate. Moreover, fostering a culture of collaboration within teams encourages diverse perspectives, leading to innovative solutions and practices that drive ongoing improvements. Through a systematic approach to refining control techniques, organizations can unlock the full potential of their systems, ensuring they remain agile and competitive in a rapidly evolving landscape.

Related Posts

-

What is Control Engineering and Why It Matters in Modern Industry

-

10 Control Engineering Tips to Enhance Your System Performance and Efficiency

-

Mastering Control Engineering 10 Essential Digital Tips for Boosting Efficiency and Reducing Costs

-

How to Choose the Best Automation Panels for Your Business Needs in 2025

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

The Rise of Control Cubicles in Modern Workspaces Enhancing Productivity and Employee Satisfaction