How to Master Panel PLC Programming: Tips and Techniques for Beginners

In the rapidly evolving world of industrial automation, mastering panel PLC programming has become an essential skill for professionals aiming to streamline processes and enhance productivity. John Doe, a renowned expert in the field of industrial control systems, once noted, "Understanding the intricacies of panel PLC programming is not just about coding, but about solving real-world problems through intelligent automation." This sentiment captures the essence of what it means to truly excel in this discipline.

For beginners, the journey into panel PLC programming may seem daunting, filled with complex terminologies and technical challenges. However, by embracing foundational concepts and applying practical techniques, aspiring programmers can demystify the process. This guide aims to equip newcomers with valuable insights and strategies that will pave the way toward proficiency in panel PLC programming. With the right knowledge and approach, anyone can transform their understanding into effective programming solutions that drive operational success.

Understanding the Basics of Panel PLC Programming

Understanding the basics of Panel PLC programming is essential for anyone looking to dive into the world of industrial automation and control systems. Panel Programmable Logic Controllers (PLC) serve as the backbone for many manufacturing processes, translating complex logic into manageable commands that control machinery and processes. At its core, Panel PLC programming is about understanding how to use input and output devices, along with controlling systems through a programming interface. Familiarizing oneself with these fundamental components is the first step in mastering the art of PLC programming.

To begin, it’s crucial to understand the fundamental structure of a PLC program, which typically includes inputs, outputs, and the logic that connects them. Inputs are the signals received from sensors or switches, while outputs control actuators or displays based on the programmed logic. Learning basic programming languages used in PLCs, such as Ladder Logic or Functional Block Diagram, will empower beginners to create effective programs that control machinery with precision. Additionally, grasping concepts like timers, counters, and Boolean logic is vital, as these elements form the basis of complex program functions. By building a strong foundational understanding, newcomers can then explore more advanced programming techniques and create efficient automation solutions for various applications.

Essential Components of Panel PLC Systems

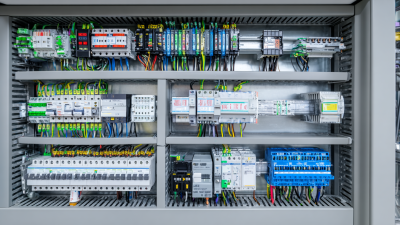

When delving into panel PLC systems, understanding the essential components is crucial for beginners looking to master programming. At the heart of any PLC system lies the Programmable Logic Controller itself, which serves as the brain of the operation. This digital computer is programmed to control machinery and processes, executing commands based on inputs from various sensors. A solid grasp of how the PLC interfaces with these sensors—such as limit switches, temperature sensors, and pressure transducers—forms the foundation of effective programming.

In addition to the PLC, other vital components include the input and output modules. The input modules translate signals from the sensors into data that the PLC can process, while output modules send control signals to actuators, motors, or other machinery based on the PLC's logic. Understanding the communication protocols, wiring practices, and the role of each component within the panel ensures that new programmers can create efficient and reliable systems. Additionally, familiarizing oneself with power supplies and grounding techniques is essential to maintain system stability and prevent damage. With these fundamentals in place, beginners are well on their way to mastering panel PLC programming.

How to Master Panel PLC Programming: Tips and Techniques for Beginners - Essential Components of Panel PLC Systems

| Component | Description | Function | Example Application |

|---|---|---|---|

| PLC Controller | The main control unit that processes inputs and controls outputs based on the programmed logic. | Controls machinery, processes, or systems in manufacturing. | Automated assembly lines. |

| Input Devices | Sensors and switches that provide data to the PLC. | Detects physical phenomena like pressure, temperature, or position. | Temperature sensors in HVAC systems. |

| Output Devices | Devices like motors, lights, and actuators that perform actions based on PLC commands. | Executes commands to control field devices. | Controlling conveyor belts or robotic arms. |

| Programming Software | Software used to write and upload programs to the PLC. | Provides a user interface for programming logic. | Visual programming for ladder logic. |

| Communication Protocols | Protocols that allow PLCs to communicate with other devices and systems. | Facilitates data exchange between devices. | Ethernet/IP for industrial networks. |

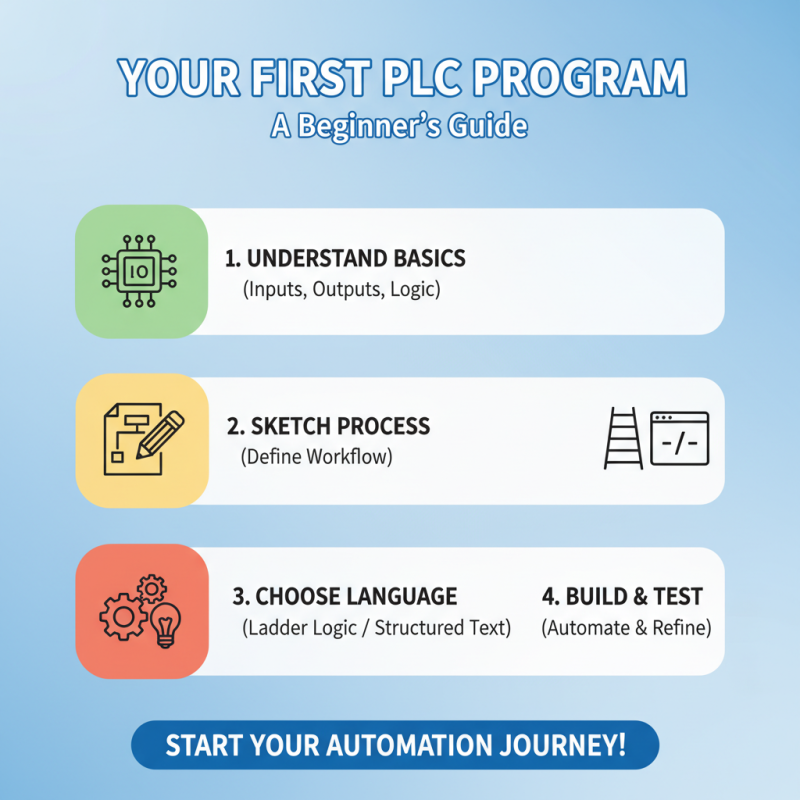

Step-by-Step Guide to Writing Your First PLC Program

Creating your first PLC program can be an exciting yet challenging endeavor. To get started, it's essential to familiarize yourself with the basic components of a PLC, including inputs, outputs, and the programming languages commonly used, such as ladder logic or structured text. Begin by sketching out the process you want to automate. This could involve defining a simple workflow that involves starting and stopping motors, reading sensor inputs, or controlling lights. Taking this initial step will give you a clear roadmap to follow as you construct your program.

Once you have a conceptual understanding of the task, the next phase is to break it down into logical steps. Start by configuring the inputs and outputs in your programming environment, which might involve assigning specific addresses to your sensors and actuators. From there, you can create the program structure, implementing the control logic through various programming elements. As you write your code, remember to simulate the process if possible, allowing you to troubleshoot and optimize your program before deploying it in a live scenario. Testing is a critical element, so ensure that you validate each part of your code to guarantee proper functionality and performance.

Common Mistakes to Avoid in Panel PLC Programming

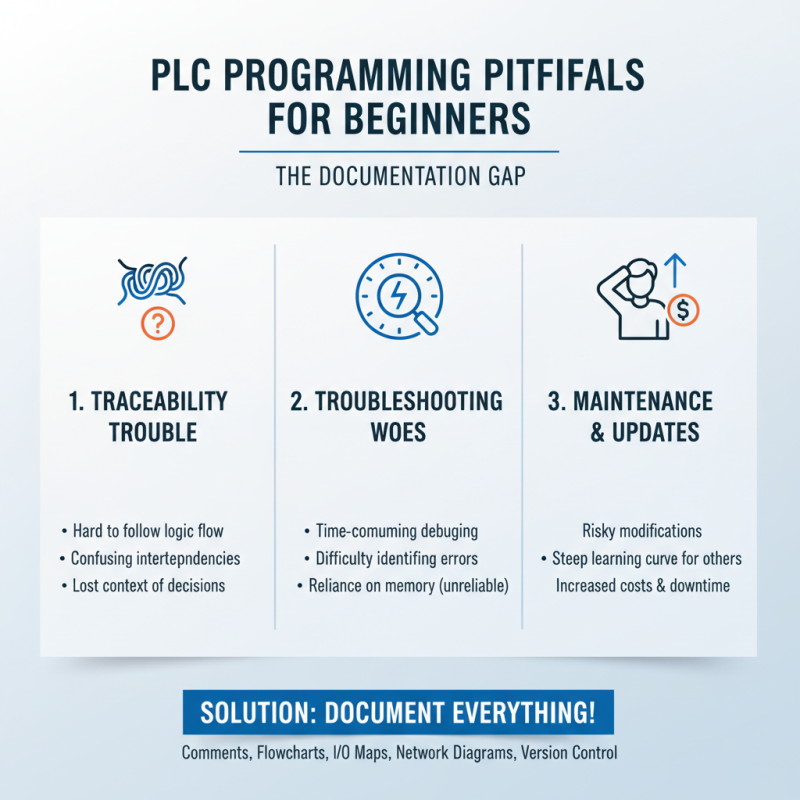

When diving into panel PLC programming, beginners often stumble into common pitfalls that can hinder their progress. One prevalent mistake is the failure to document the programming process adequately. Without thorough documentation, it becomes challenging to trace back steps, understand decisions made during the programming phase, or provide a clear guide for future reference. This oversight can lead to confusion when troubleshooting issues or making updates, ultimately wasting time and resources.

Another frequent error is underestimating the importance of simulation and testing. Many novices rush to implement their code without taking the time to run simulations to verify the program’s logic. Testing in a controlled environment allows programmers to identify and rectify issues before deploying to the actual machinery, thereby preventing costly downtime and ensuring a smoother operation. By dedicating time to thorough testing and simulation, beginners can enhance their understanding and confidence in panel PLC programming.

Best Practices for Troubleshooting Panel PLC Issues

When it comes to troubleshooting Panel PLC issues, developing a systematic approach is essential for identifying and resolving problems efficiently. Start by understanding the PLC’s basic operational parameters and the specific processes it controls. Familiarize yourself with the wiring diagrams and system configuration to ensure that all components are functioning as intended. Always check for simple issues first, such as loose connections, power supply problems, or faulty sensors, as these are the most common culprits behind PLC malfunctions.

Once you've assessed the physical setup, move on to the software side of the PLC. Utilize diagnostic tools and monitoring features available in the PLC programming environment. These tools can help identify errors in logic, such as incorrect programming sequences or conditional statements that may lead to unexpected behaviors. Keep a detailed log of observed symptoms and corresponding changes made, as this documentation can be invaluable for future troubleshooting sessions. By having a structured methodology, you can minimize downtime and improve the reliability of your Panel PLC operations.

Related Posts

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

How to Master PLC Controller Programming for Industrial Automation

-

Revolutionizing Manufacturing Control Systems Insights from the 138th China Import and Export Fair 2025

-

Top 10 Benefits of Using PLC Control in Industrial Automation Solutions

-

Top 10 Benefits of Using PLC Control Panels in Industrial Automation

-

What Are Electrical Control Solutions and How Do They Revolutionize Automation?