Unlocking the Secrets of Motor Power Efficiency for Sustainable Energy Solutions

The quest for sustainable energy solutions has brought to the forefront the significance of motor power efficiency, a topic that is increasingly pivotal in both industrial applications and environmental stewardship. According to a report by the International Energy Agency (IEA), electric motors account for approximately 45% of global electricity consumption in industrial sectors, emphasizing the need for enhanced motor power efficiency to reduce energy waste and greenhouse gas emissions. Furthermore, the U.S. Department of Energy estimates that improving the efficiency of electric motors could unlock energy savings equivalent to about $14 billion annually. As industries strive to meet carbon reduction targets and invest in cleaner technologies, understanding the underlying principles of motor power efficiency becomes essential for developing innovative strategies that align economic growth with sustainability goals. Thus, this discourse delves into the secrets of optimizing motor power, paving the way for effective energy solutions that benefit both businesses and the environment.

Exploring the Fundamentals of Motor Power Efficiency in Renewable Energy Applications

The exploration of motor power efficiency is crucial for harnessing renewable energy applications effectively. The global energy-efficient motor market, projected to grow significantly from $54.60 billion in 2025 to $80.86 billion by 2032, underscores the increasing focus on sustainability in energy production. This trend is driven by the need for enhanced energy performance and reduced environmental impact, as industries seek cost-effective solutions that do not compromise on efficiency.

In particular, advancements such as the integration of nano-additives in diesel engines, including Cerium oxide, Zinc oxide, and Titanium oxide, present promising pathways for improving fuel efficiency and sustainability. Moreover, technologies like solar-powered Stirling engines exemplify the potential of converting solar energy into electricity with remarkable efficiency. As industries and researchers continue to prioritize innovations in motor power efficiency, the move toward more sustainable energy solutions is not only viable but essential for future developments in the renewable energy sector.

Motor Power Efficiency in Renewable Energy Applications

This chart illustrates the efficiency of various types of electric motors used in renewable energy applications. The data is based on average efficiencies measured for DC motors, AC motors, and stepper motors, showcasing their performance in sustainable energy solutions.

Key Strategies for Enhancing Motor Efficiency through Digital Innovations

Digital innovations play a crucial role in enhancing motor efficiency, paving the way for sustainable energy solutions. One key strategy involves the integration of advanced sensors and real-time monitoring systems. By employing Internet of Things (IoT) technology, these systems allow for continuous tracking of motor performance, enabling timely maintenance and minimizing energy wastage. Predictive analytics can be used to foresee potential failures and optimize operational conditions, thereby improving overall power efficiency.

Another significant approach is the implementation of smart control algorithms that adapt motor performance based on variable load conditions. These algorithms utilize machine learning techniques to analyze past performance data, allowing motors to adjust their energy consumption dynamically. This not only maximizes efficiency but also reduces the carbon footprint associated with energy-intensive operations. In addition, digital twins can simulate motor behavior in different scenarios, aiding in the design of more efficient systems tailored to specific needs. Through these innovations, the motor industry can achieve remarkable gains in efficiency while contributing to a more sustainable energy landscape.

Unlocking the Secrets of Motor Power Efficiency for Sustainable Energy Solutions - Key Strategies for Enhancing Motor Efficiency through Digital Innovations

| Strategy | Expected Efficiency Improvement (%) | Implementation Cost ($) | Payback Period (Years) |

|---|---|---|---|

| Variable Frequency Drives (VFDs) | 15-30 | 2,000 | 1-3 |

| Motor Replacement with High-Efficiency Models | 20-40 | 5,000 | 2-5 |

| Condition Monitoring Systems | 10-25 | 1,500 | 1-4 |

| Thermal Management Solutions | 5-15 | 3,000 | 1-3 |

| Advanced Control Algorithms | 15-35 | 2,500 | 1-2 |

Comparative Analysis of Energy Loss in Different Motor Designs

When analyzing energy loss in different motor designs, it's crucial to understand how efficiency varies across various types of electric motors. According to the International Electrotechnical Commission (IEC), induction motors, which account for about 60% of global energy consumption for electric motors, can achieve efficiencies of up to 95%. However, losses can still rise dramatically due to friction, heat, and electromagnetic losses. This emphasizes the importance of selecting the right motor design to minimize waste.

In contrast, permanent magnet synchronous motors (PMSMs) have demonstrated even greater efficiency, often exceeding 96%. Reports indicate that the use of PMSMs can reduce energy consumption by approximately 30% compared to traditional induction motors. Such a substantial decrease is vital for companies aiming to enhance their sustainability profiles while decreasing operational costs.

Tips: When selecting a motor, it's essential to consider not just the initial cost but also the long-term energy savings you could achieve. Investing in high-efficiency motors like PMSMs and ensuring proper maintenance can lead to significant reductions in energy loss. Additionally, consider utilizing variable frequency drives (VFDs), which can optimize motor performance under varying loads and further enhance overall efficiency.

Tips for Monitoring and Optimizing Motor Performance in Real-Time

Real-time monitoring is essential for optimizing motor performance and enhancing energy efficiency. By implementing advanced sensors and data analytics, facility managers can track motor parameters such as temperature, vibration, and electrical consumption. These data points provide valuable insights into the operational health of motors, enabling early detection of issues that could lead to inefficiencies or failures. For instance, a sudden spike in temperature may indicate a lubrication issue or an overload condition, allowing for timely intervention.

To further improve energy efficiency, organizations should also consider integrating smart control systems that adjust motor speeds according to real-time demand. Variable frequency drives (VFDs) are an effective solution for this purpose, as they allow motors to operate only at the necessary power levels, reducing waste. Additionally, implementing performance dashboards can help teams visualize key metrics and make informed decisions to fine-tune motor operations. By adopting these strategies, businesses can significantly enhance motor power efficiency, contributing to sustainable energy practices.

Integrating Smart Technologies to Maximize Motor Efficiency for Sustainability

As industries increasingly embrace sustainability, the integration of smart technologies into motor systems is vital for maximizing efficiency.

Smart sensors and IoT devices can provide real-time data on motor performance, enabling operators to monitor and adjust settings for optimal efficiency. This adaptive approach not only reduces energy consumption but also extends the lifespan of motors, making them more sustainable in the long run.

Tips: Regularly calibrate your motors using smart diagnostic tools to ensure they are running at peak efficiency. Additionally, consider implementing predictive maintenance strategies using AI algorithms, which can foresee potential failures before they occur, further enhancing sustainability efforts.

Moreover, the use of advanced motor control systems, such as variable frequency drives (VFDs), allows for precise control over speed and torque. This level of control leads to significant energy savings, particularly in applications with variable load conditions. By optimizing motor operation based on actual demand, businesses can dramatically reduce their carbon footprint.

Tips: When upgrading motor systems, opt for those equipped with smart VFDs that can adapt to changing operational needs. This flexibility not only saves energy but also boosts overall operational efficiency.

Related Posts

-

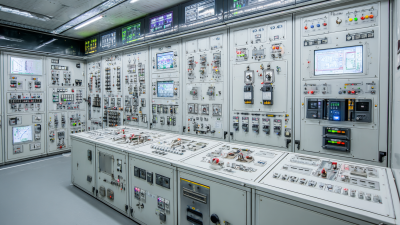

How to Optimize HMI Control Panels for Enhanced Industrial Efficiency and Performance

-

Innovative Uses of HMI Panels in Modern Industrial Automation

-

Ultimate Guide to Choosing Control Cubicles for Maximum Efficiency

-

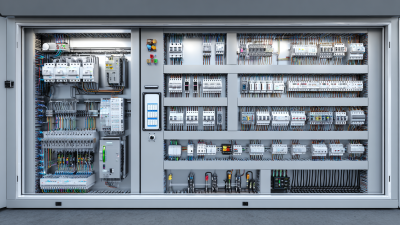

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

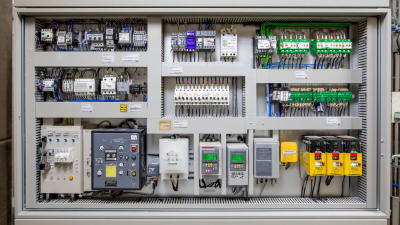

How to Create Efficient Electrical Control Panel Designs for Optimal Performance

-

5 Automation Panels Innovations You Didn't Know You Needed for Optimal Efficiency