Top 5 Ways Motor Power Optimizes Appliance Efficiency for Energy Savings

In today's rapidly evolving energy landscape, optimizing appliance efficiency has become paramount for both consumer savings and environmental sustainability. Recent industry reports indicate that electric motors account for nearly 70% of industrial energy consumption, making them significant players in the quest for energy efficiency. According to a study by the International Energy Agency (IEA), improving motor power efficiency could potentially reduce global electricity consumption by 10%, translating to billions of dollars in savings and a substantial decrease in greenhouse gas emissions.

Experts in the field emphasize the critical role of motor power in appliance performance. Dr. Emily Chen, a leading researcher in motor technology, asserts, "The future of energy-efficient appliances hinges on advancing motor power technologies, which not only enhance operational efficiency but also contribute to significant cost reductions for consumers." With effective applications of motor power, homeowners and businesses can achieve lower energy bills while simultaneously easing the burden on our planet's resources. This introduction sets the stage for exploring the top five methods by which motor power can optimize appliance efficiency, highlighting its potential for substantial energy savings.

How Motor Power Ratings Influence Energy Consumption in Home Appliances

The motor power rating of home appliances significantly influences their energy consumption, leading to impactful efficiency improvements. According to the U.S. Department of Energy, appliances with higher motor efficiency can reduce energy usage by up to 30%. This can be especially crucial for high-consumption equipment like refrigerators and air conditioners, where the motor power directly correlates with energy output and longevity. Appliances designed with energy-efficient motors not only ensure lower energy bills but also contribute to reduced greenhouse gas emissions—a key factor in combating climate change.

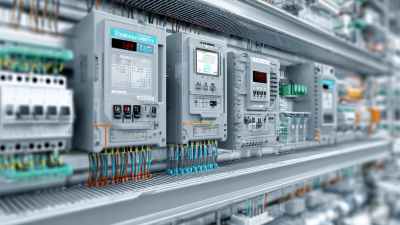

Moreover, the efficiency of motor power ratings is often quantified using the Energy Star certification, which indicates compliance with strict energy efficiency guidelines. For instance, Energy Star-rated appliances typically consume up to 50% less energy compared to non-rated models. This certification not only helps consumers make informed choices but also prompts manufacturers to innovate and improve appliance designs continuously. As a result, investing in appliances with optimized motor power ratings can yield significant energy savings, making it an essential consideration for environmentally conscious consumers.

Top 5 Ways Motor Power Optimizes Appliance Efficiency for Energy Savings

This chart illustrates the percentage of energy savings achieved through various motor power optimization strategies in home appliances. These strategies include efficiency improvements, power factor correction, reduced heat loss, load matching, and the use of variable frequency drives.

The Role of Energy-Efficient Motors in Reducing Overall Appliance Footprint

In today's energy-conscious world, the role of energy-efficient motors in appliances cannot be overstated. According to a report by the International Energy Agency (IEA), motors account for approximately 45% of the global electricity consumption in industrial applications alone. This staggering figure highlights the urgent need for integrating energy-efficient motors into household and commercial appliances. By utilizing motors that meet or exceed efficiency standards, manufacturers can significantly reduce the overall energy footprint of their products—leading not only to lower electricity bills for consumers but also to decreased carbon emissions.

One essential tip for consumers looking to optimize energy use is to prioritize appliances equipped with high-efficiency motors, such as those rated by ENERGY STAR. These motors are designed to perform better and consume less energy, thus contributing to significant energy savings over their lifespan. Additionally, regular maintenance of these appliances can ensure motors operate at peak efficiency, further extending energy savings.

Another noteworthy statistic from the U.S. Department of Energy indicates that upgrading to energy-efficient motors can decrease energy costs by 10-50%. For both consumers and manufacturers, this presents a powerful incentive to invest in technology that stands to benefit the environment while also delivering substantial economic rewards. By adopting energy-efficient motors, we can take a significant step toward reducing our collective energy footprint.

Comparative Analysis of Motor Technologies and Their Impact on Energy Usage

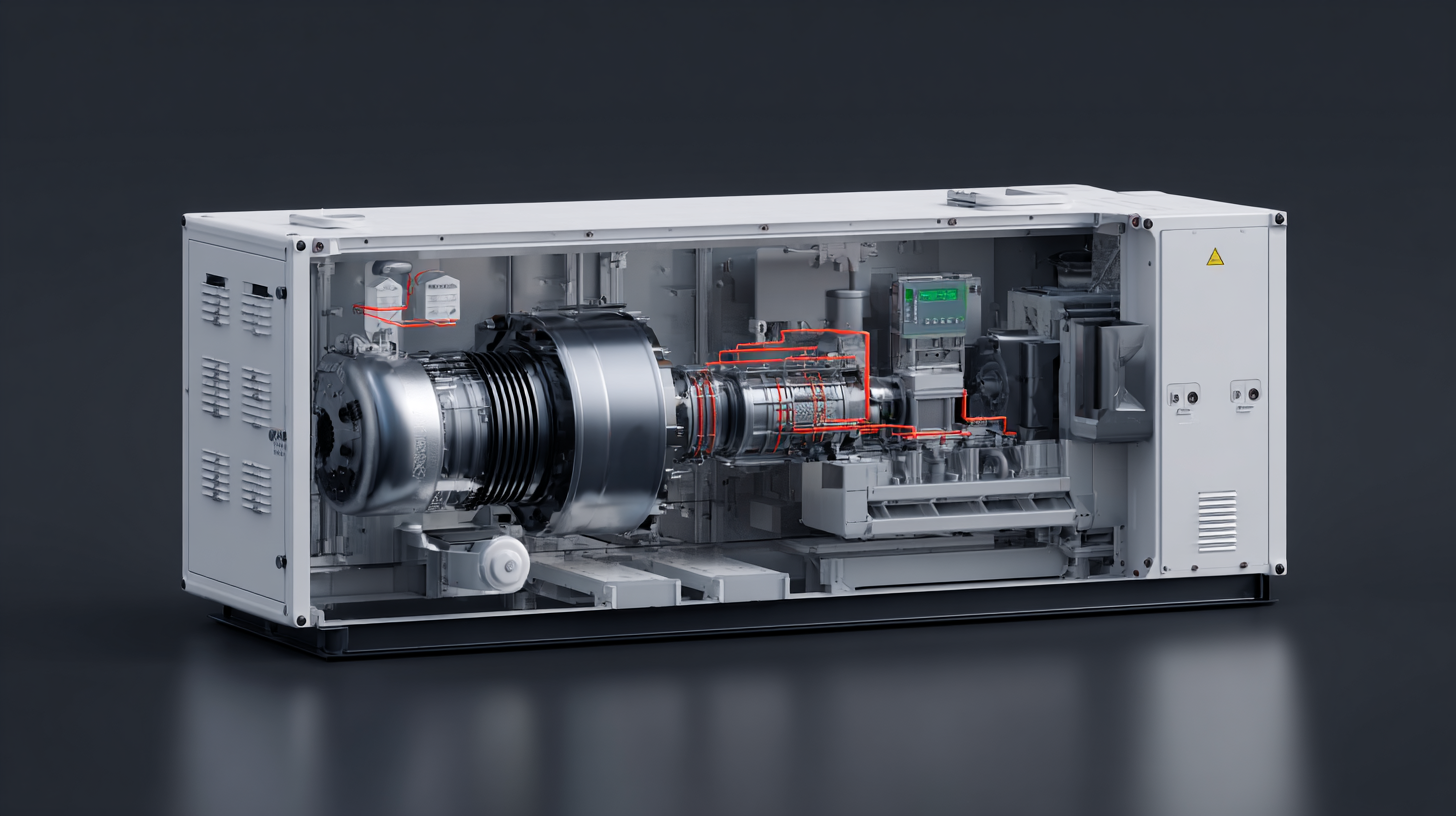

Motor technologies play a crucial role in enhancing the efficiency of appliances, ultimately leading to significant energy savings. When comparing various motor types, such as induction motors, brushless DC motors, and stepper motors, it's evident that their designs directly influence energy consumption. Induction motors, which operate on electromagnetic induction, are widely used due to their robustness and simplicity. However, advancements in brushless DC technologies offer higher efficiency and reduced energy losses, making them preferable in applications where efficiency is paramount.

Moreover, stepper motors, known for their precise control and positioning, are increasingly being utilized in various appliances, especially where energy efficiency is critical. Their ability to operate at lower power levels without sacrificing performance allows manufacturers to create devices that consume less energy while maintaining functionality. The comparative analysis of these motor technologies reveals that selecting the appropriate motor type not only impacts the initial cost but also significantly influences long-term energy usage, leading to both economic and environmental benefits for consumers.

Case Studies: Proven Energy Savings from Upgrading to High-Efficiency Motors

Upgrading to high-efficiency motors can lead to significant energy savings, as demonstrated by several case studies across various industries. For instance, a manufacturing plant that replaced its aging, low-efficiency motors with high-efficiency models achieved a remarkable 20% reduction in energy costs. This not only decreased their operational expenditures but also extended the lifespan of their equipment, showcasing the dual benefits of financial and operational efficiency.

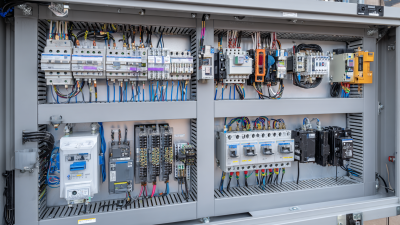

Tips: When considering a motor upgrade, it's essential to evaluate your current energy consumption and identify the most critical areas for improvement. Conducting an energy audit can highlight specific machines that are prime candidates for replacement. Additionally, consider the potential return on investment (ROI) from energy savings when selecting motor types.

Another notable case involved a commercial refrigeration unit that integrated high-efficiency motors, resulting in a 30% decrease in energy usage over the course of a year. These upgrades not only positively impacted the bottom line but also contributed to sustainability goals, aligning with corporate responsibility initiatives. By leveraging such case studies, businesses can make informed decisions that promote both energy savings and eco-friendliness.

Tips: Collaborate with energy service providers to explore available incentives and rebates for upgrading to high-efficiency motors. This can significantly lower upfront costs and enhance the motivation for making the switch.

Consumer Awareness: Understanding Motor Power Specifications for Savings

When it comes to optimizing appliance efficiency, understanding motor power specifications is crucial for consumers seeking energy savings. Many people are unaware that the power rating of a motor significantly impacts both performance and energy consumption. By educating themselves about these specifications, consumers can make informed decisions when purchasing appliances, ultimately leading to lower energy bills and a smaller carbon footprint.

To maximize energy savings, consumers should consider looking for appliances with high-efficiency motors (HEMs). These motors are designed to operate using less energy while delivering the same level of performance. Additionally, checking for the Energy Star label can ensure that the appliance meets strict energy efficiency guidelines, providing further assurance of savings over time.

Another key tip is to pay attention to the appliance's horsepower (HP) rating. A higher HP often indicates more power but can also lead to increased energy usage. Consumers should evaluate whether they truly need that much power for their specific needs. Furthermore, understanding the duty cycle of the appliance—how often and for how long it will be used—can help in choosing the right motor power, balancing performance and efficiency for improved savings.

Related Posts

-

Unlocking the Secrets of Motor Power Efficiency for Sustainable Energy Solutions

-

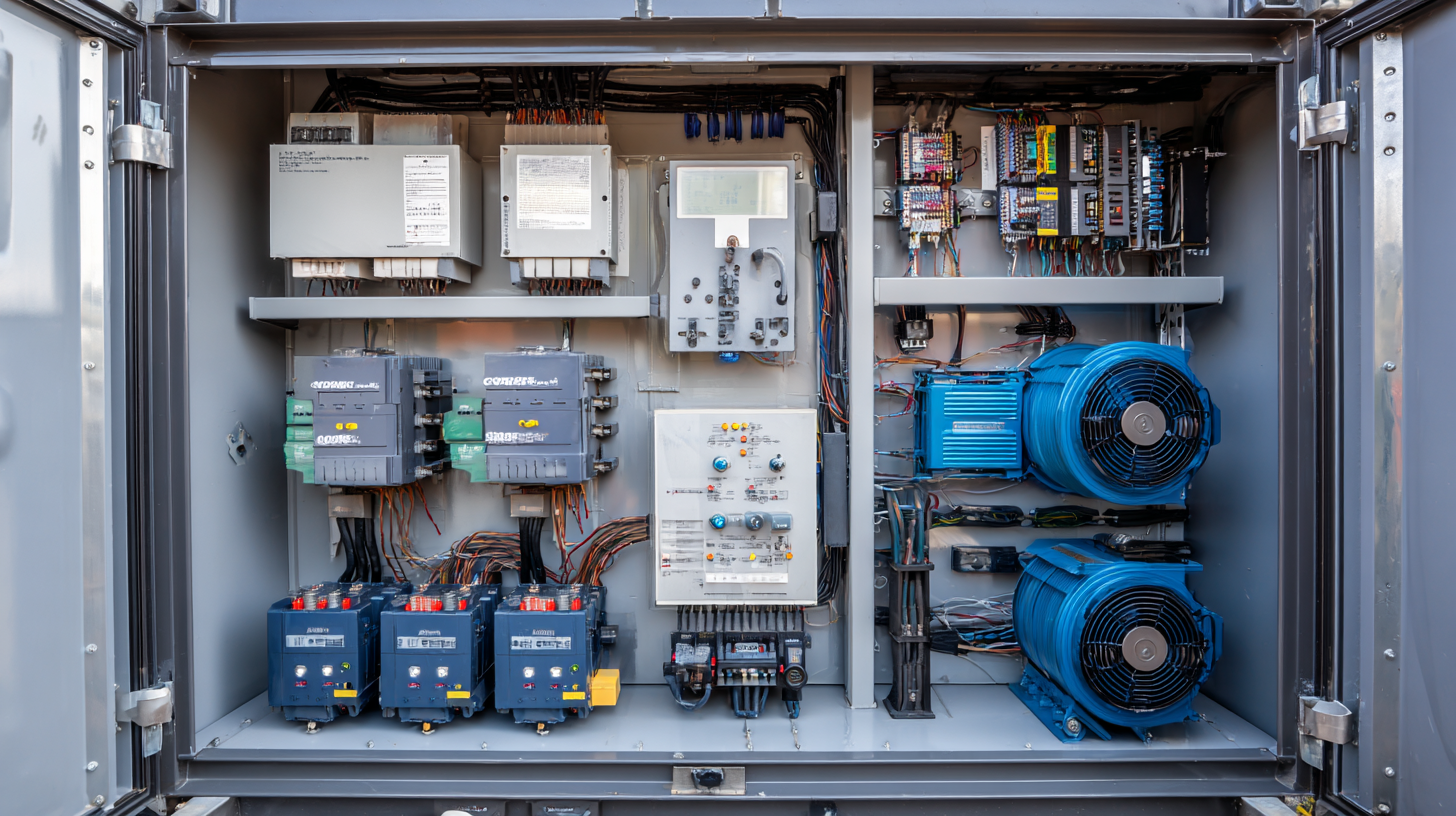

How to Optimize Your Power Distribution Control System for Maximum Efficiency

-

How to Optimize Your Manufacturing Efficiency with VFD Control Panels

-

Top 5 Essential Control Systems for Optimizing Industrial Automation

-

5 Essential Tips for Optimizing Your Pneumatic Control Panel Efficiency

-

How to Master Electrical Control Panel Design for Your Next Project