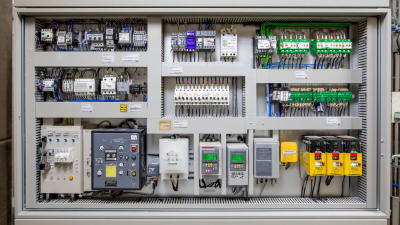

Revolutionizing Industries with Next Generation Automation Control Panels

The advent of next-generation automation control panels is set to transform various industries by enhancing operational efficiency and productivity. According to a report by MarketsandMarkets, the global automation control market is projected to reach $269.3 billion by 2025, growing at a CAGR of 6.2%. This surge can be attributed to the increasing demand for automation across manufacturing, energy, and transportation sectors.

Automation control panels play a pivotal role in this evolution, as they facilitate real-time monitoring and control of processes, significantly reducing human error and downtime. As industries embrace smart technologies and the Internet of Things (IoT), the integration of sophisticated automation control panels will not only streamline operations but also contribute to sustainability goals, ultimately revolutionizing the way industries operate in an increasingly competitive landscape.

Automation control panels play a pivotal role in this evolution, as they facilitate real-time monitoring and control of processes, significantly reducing human error and downtime. As industries embrace smart technologies and the Internet of Things (IoT), the integration of sophisticated automation control panels will not only streamline operations but also contribute to sustainability goals, ultimately revolutionizing the way industries operate in an increasingly competitive landscape.

Transforming Manufacturing Processes with Smart Automation Technologies

The manufacturing sector is undergoing a significant transformation driven by the integration of smart automation technologies. According to a report by McKinsey, factories that adopt advanced automation technologies can increase productivity by up to 20%, significantly enhancing their overall efficiency. This shift towards automation not only streamlines production processes but also reduces operational costs, allowing manufacturers to allocate resources more effectively.

Smart automation technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), empower manufacturers to collect and analyze real-time data, leading to more informed decision-making. A study by the World Economic Forum suggests that implementing these technologies can lead to a 10-15% decrease in production downtime and improve product quality by identifying defects earlier in the manufacturing process. As industries continue to embrace these innovations, the landscape of manufacturing is set to become more agile, responsive, and capable of meeting the challenges of a rapidly evolving market.

Revolutionizing Industries with Next Generation Automation Control Panels

| Industry | Automation Technology | Benefits | Implementation Time (months) | Cost Savings (%) |

|---|---|---|---|---|

| Manufacturing | Robotic Process Automation | Increased efficiency, reduced labor costs | 6 | 20 |

| Logistics | Automated Guided Vehicles | Improved delivery times, enhanced safety | 9 | 15 |

| Healthcare | Smart Monitoring Systems | Improved patient outcomes, reduced errors | 12 | 25 |

| Food and Beverage | Process Automation Systems | Consistent quality, reduced waste | 8 | 18 |

| Textile | Computerized Control Systems | Faster production, better resource management | 10 | 22 |

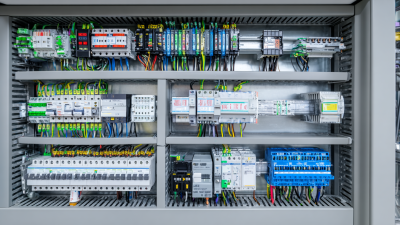

Integrating AI and Machine Learning into Control Panel Design

The integration of AI and machine learning into control panel design is transforming how industries operate, making processes more efficient and responsive. Traditional control panels often rely on predefined instructions, but with the advent of smart technologies, these systems can now learn from data patterns and adapt in real-time. This allows for predictive maintenance and optimization of performance, minimizing downtime and improving overall productivity.

Tips: When redesigning control panels, consider incorporating sensors that collect data continuously. This will enable your AI algorithms to analyze trends and make intelligent decisions based on historical and real-time data. Additionally, ensure that your team is trained to understand and interpret the insights generated by AI to make informed adjustments in operations.

Tips: Collaborate with AI experts during the design phase to ensure that your control panel is not only integrated with cutting-edge technology but also user-friendly. Regularly update your software to keep pace with advancements in machine learning, allowing your systems to continuously improve their functionality over time.

Enhancing Safety and Efficiency with Next Gen Automation Solutions

The next generation of automation control panels is set to significantly enhance safety and efficiency across various industries. Recent advancements in technology, particularly in machine vision, are proving instrumental in improving automation processes. Sophisticated machine vision systems are capable of overseeing operations with higher accuracy, thereby minimizing risks associated with human error. According to industry reports, companies that have integrated these systems have reported a reduction in accidents by up to 30%, showcasing a clear link between advanced technologies and workplace safety.

Furthermore, the ongoing transformation in sectors such as mining through automation and AI is pushing the boundaries of operational efficiency. By 2025, the autonomous mining industry is projected to save over 20% in operational costs while increasing safety measures significantly. These innovations not only facilitate safer environments for workers but also contribute to sustainable practices by optimizing resource usage. As companies adopt next-gen automation solutions, they are realizing not only improved efficiency but also enhanced operational resilience, making future industries safer and more effective.

Impact of Next Generation Automation Control Panels on Safety and Efficiency

This chart illustrates the significant improvements in safety and efficiency achieved through the implementation of next generation automation control panels over the course of a year. The data indicates a consistent upward trend in both metrics, emphasizing the effectiveness of advanced automation solutions.

Customizing Automation Control for Diverse Industrial Applications

The evolving landscape of automation control panels is fundamentally transforming industrial applications across various sectors. According to a market research study released by Custom Market Insights, the global automation control market is projected to witness substantial growth, with an estimated CAGR of approximately 10% from 2023 to 2030. This surge reflects an increasing demand for customized automation solutions tailored to meet the unique requirements of different industries, including manufacturing, energy, and logistics.

Customizing automation control systems allows industries to enhance operational efficiency, reduce downtime, and improve production quality. The report emphasizes that industries are increasingly investing in next-generation automation technologies to streamline processes. For instance, tailored control panels equipped with advanced analytics and real-time monitoring capabilities facilitate better decision-making in adaptive manufacturing environments. As industries strive for digital transformation, the need for personalized automation solutions becomes evident, enabling them to remain competitive in an ever-evolving market landscape. By aligning automation control systems with specific industrial needs, organizations can leverage significant improvements in productivity and sustainability.

Future Trends in Automation: Towards Fully Autonomous Systems

As industries evolve, the push towards fully autonomous systems is not just a trend but a necessity for enhancing efficiency and productivity. Recent reports indicate that the global industrial automation market is projected to reach $296.70 billion by 2026, growing at a CAGR of 9.2% from 2019 to 2026 (ResearchAndMarkets, 2021). This transformation is closely tied to advancements in automation control panels, which are increasingly integrating AI and machine learning capabilities to optimize operations. These next-generation systems are designed to make real-time decisions, significantly reducing human intervention and the associated errors.

Tips: When considering the implementation of automation control panels, take stock of your current operational processes. Evaluate where automation can bring the most significant improvement, particularly in repetitive or complex tasks that require precision.

As companies adopt these technologies, the focus is shifting toward modular and scalable solutions that adapt to changing needs. According to a study by McKinsey, up to 45% of current work activities could be automated with the right technology in place, indicating a substantial shift towards an autonomous future. Embracing this shift not only streamlines production but also enhances data analytics capabilities, paving the way for smarter decision-making.

Tips: Invest in training programs for your workforce to equip them with the skills needed to manage and optimize new automation technologies. A well-prepared team will ensure a smooth transition into a more automated environment.

Related Posts

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

What Are Electrical Control Solutions and How Do They Revolutionize Automation?

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency

-

What is the Importance of PLC Programming in Modern Automation

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

How to Optimize HMI Control Panels for Enhanced Industrial Efficiency and Performance