How to Optimize Control Systems for Improved Efficiency and Performance

In today's rapidly evolving industrial landscape, the efficiency and performance of control systems are paramount for businesses striving to maintain competitiveness and sustainability. According to a report by the International Society of Automation, optimizing control systems can lead to as much as a 30% increase in operational efficiency, significantly reducing energy consumption and costs. As industries increasingly embrace automation and smart technologies, the push for more effective control systems becomes even more critical.

Moreover, a study from the McKinsey Global Institute highlights that enhancements in control system design and implementation can contribute to a 20% improvement in overall productivity. This underscores the necessity for organizations to adopt advanced control mechanisms that not only streamline processes but also enable real-time data analysis and decision-making. As manufacturers and operators look for ways to enhance their systems, understanding the dynamics of control systems will be essential to unlock their full potential and drive future growth.

In light of these findings, this article explores strategies to optimize control systems, focusing on methodologies that can substantially uplift both efficiency and performance, ensuring that organizations remain agile in a competitive marketplace.

Strategies for Integrating Advanced Sensors in Control Systems

Integrating advanced sensors into control systems is pivotal for enhancing operational efficiency and performance across various industries, notably in defense and automotive sectors. Recent advancements, such as the deployment of next-gen smart chassis sensors, highlight the potential of incorporating integrated accelerometers that provide enhanced motion detection capabilities. This integration results in increased data intelligence, supporting more agile and informed decision-making processes, which is crucial in high-stakes environments like military operations.

Moreover, the rise of autonomous technologies in the vehicle sector underscores the necessity for advanced control systems that leverage complex sensor arrays. Companies leading the way in autonomous vehicle development utilize an extensive range of sensing technologies to gather real-time data, optimizing navigation and safety protocols. According to recent market analyses, the global automotive robotics market is projected to witness significant growth, driven by the ongoing transformation towards automation in vehicle manufacturing and the broader Industry 4.0 movement. Such innovations not only improve efficiency but also pave the way for robust, responsive systems that can adapt to dynamic operational landscapes, clarifying the integral role of sensor integration in modern control systems.

Enhancing Algorithm Efficiency for Real-Time Performance Optimization

In modern control systems, enhancing algorithm efficiency is crucial for achieving real-time performance optimization. Real-time systems often face challenges such as time constraints, resource limitations, and the need for quick decision-making. To address these challenges, developers are increasingly focusing on optimizing algorithms that control dynamic systems. By refining the algorithms, it's possible to reduce computational overhead, thereby increasing response times and improving overall system performance.

**Tip 1:** Prioritize algorithm complexity. When designing control algorithms, consider minimizing complexity by using simple mathematical models where applicable. This can significantly reduce computation time, allowing the control system to respond more swiftly to changes in the environment.

**Tip 2:** Implement parallel processing. Leveraging multi-core processors or distributed computing can enhance the execution speed of control algorithms. By splitting tasks across multiple processors, the system can manage more operations simultaneously, leading to faster data processing and improved real-time performance.

In addition, continuous monitoring and adjustment of control parameters are vital for maintaining optimal performance. Algorithms should be adaptable, allowing them to tune themselves based on real-time feedback from the system. This adaptive capability keeps the control system efficient even as operating conditions change.

How to Optimize Control Systems for Improved Efficiency and Performance

| Control System Type | Optimization Algorithm | Efficiency Gain (%) | Performance Metric | Real-Time Response (ms) |

|---|---|---|---|---|

| PID Controller | Genetic Algorithm | 15 | Settling Time | 50 |

| Fuzzy Logic Controller | Particle Swarm Optimization | 20 | Overshoot | 40 |

| State Space Controller | Simulated Annealing | 10 | Control Signal Variance | 45 |

| Model Predictive Controller | Gradient Descent | 25 | Tracking Error | 30 |

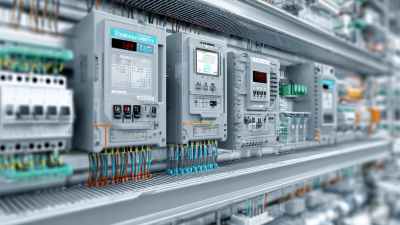

Leveraging Data Analytics for Predictive Maintenance and Control

The integration of data analytics in control systems has revolutionized various industries by enabling predictive maintenance solutions that enhance efficiency and performance. According to recent market analysis, the global control systems market is projected to reach approximately $25 billion by 2026, growing at a significant compound annual growth rate (CAGR). Key segments within this market include Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC), crucial for applications in sectors such as oil and gas, chemicals, and food processing. These systems facilitate seamless data exchange and real-time monitoring, paving the way for proactive decision-making.

Tips: Implementing data-driven strategies for predictive maintenance can lead to a reduction in unplanned downtime by up to 30%, making your operations more reliable. Additionally, leveraging AI capabilities can enhance the predictive accuracy of maintenance schedules, ultimately saving costs and extending the lifespan of machinery.

Furthermore, as industries increasingly adopt intelligent manufacturing practices, the role of AI and machine learning in building more responsive control systems becomes evident. Reports indicate that the AI sector in manufacturing will see an influx of investment, with expectations to transcend $6 billion by 2025. Emphasizing the importance of data management, manufacturers must focus on harnessing their operational data effectively to foster an environment of continuous improvement and innovation.

Adopting Modular Design Approaches for Flexible Control Systems

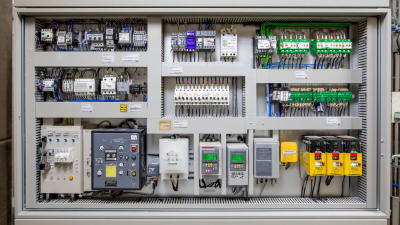

Modular design approaches have emerged as a pivotal strategy for enhancing the flexibility and responsiveness of control systems. By incorporating modular components, engineers can create systems that are not only easier to configure but also more resilient to changes in operational requirements. This adaptability allows for swift adjustments in system functionality without the need for complete redesigns, significantly reducing downtime and cost.

Furthermore, modular designs facilitate the integration of advanced technologies and new functionalities over time. As the demands on control systems evolve, the ability to interchange or upgrade individual modules ensures that the system can keep pace with technological advancements and market needs. This kind of scalability not only improves efficiency but also enhances the overall performance of the control system by allowing for the seamless incorporation of innovations such as artificial intelligence and machine learning for predictive analytics. Through the strategic use of modularity, organizations can optimize their control systems, ensuring they are both effective and future-proof.

Control Systems Efficiency Comparison

This bar chart represents the efficiency of control systems before and after adopting a modular design approach. The optimization led to a marked improvement in system efficiency, demonstrating the benefits of flexible control systems for enhanced performance.

Implementing Energy Management Techniques to Boost System Efficiency

Implementing energy management techniques is crucial for enhancing the efficiency of control systems, particularly in industrial environments where energy consumption can significantly impact operational costs. One of the first steps in this process is the integration of real-time monitoring systems. By continuously tracking energy usage across various components, organizations can identify inefficiencies and potential areas for optimization. Advanced data analytics tools can further analyze this data to pinpoint trends, enabling predictive maintenance and reducing unexpected downtimes.

Another essential technique is the adoption of variable frequency drives (VFDs) in motor control systems. VFDs allow for precise control of motor speeds, which leads to a significant reduction in energy consumption when compared to traditional systems that operate at fixed speeds. Additionally, the implementation of energy-efficient algorithms in control systems can dynamically adjust parameters based on real-time conditions, thereby optimizing performance and reducing waste. Emphasizing these energy management techniques ensures that control systems are not only more efficient but also aligned with sustainability goals, contributing to a greener future.

Related Posts

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

What Are Electrical Control Solutions and How Do They Revolutionize Automation?

-

Revolutionizing Industries with Next Generation Automation Control Panels

-

Top 5 Essential Control Systems for Optimizing Industrial Automation

-

Top 10 Electrical Control Systems Revolutionizing Industrial Automation

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration