How to Optimize Your Electrical Control Panel Design for Maximum Efficiency and Safety

In today's fast-paced industrial environment, optimizing electrical control panel design is crucial to achieving maximum efficiency and ensuring safety. According to the National Electrical Manufacturers Association (NEMA), well-designed control panels can improve operational efficiency by up to 30%, while simultaneously reducing downtime and maintenance costs. Furthermore, the International Electrotechnical Commission (IEC) emphasizes that adhering to stringent safety standards in panel design can prevent approximately 80% of electrical hazards. As companies strive to maintain competitiveness in their sectors, investing in advanced control panel designs that prioritize both performance and safety is essential.

This article outlines key strategies to optimize electrical control panels, ensuring they meet the rigorous demands of modern industrial applications while safeguarding personnel and equipment.

Understanding the Role of Electrical Control Panels in Operational Efficiency

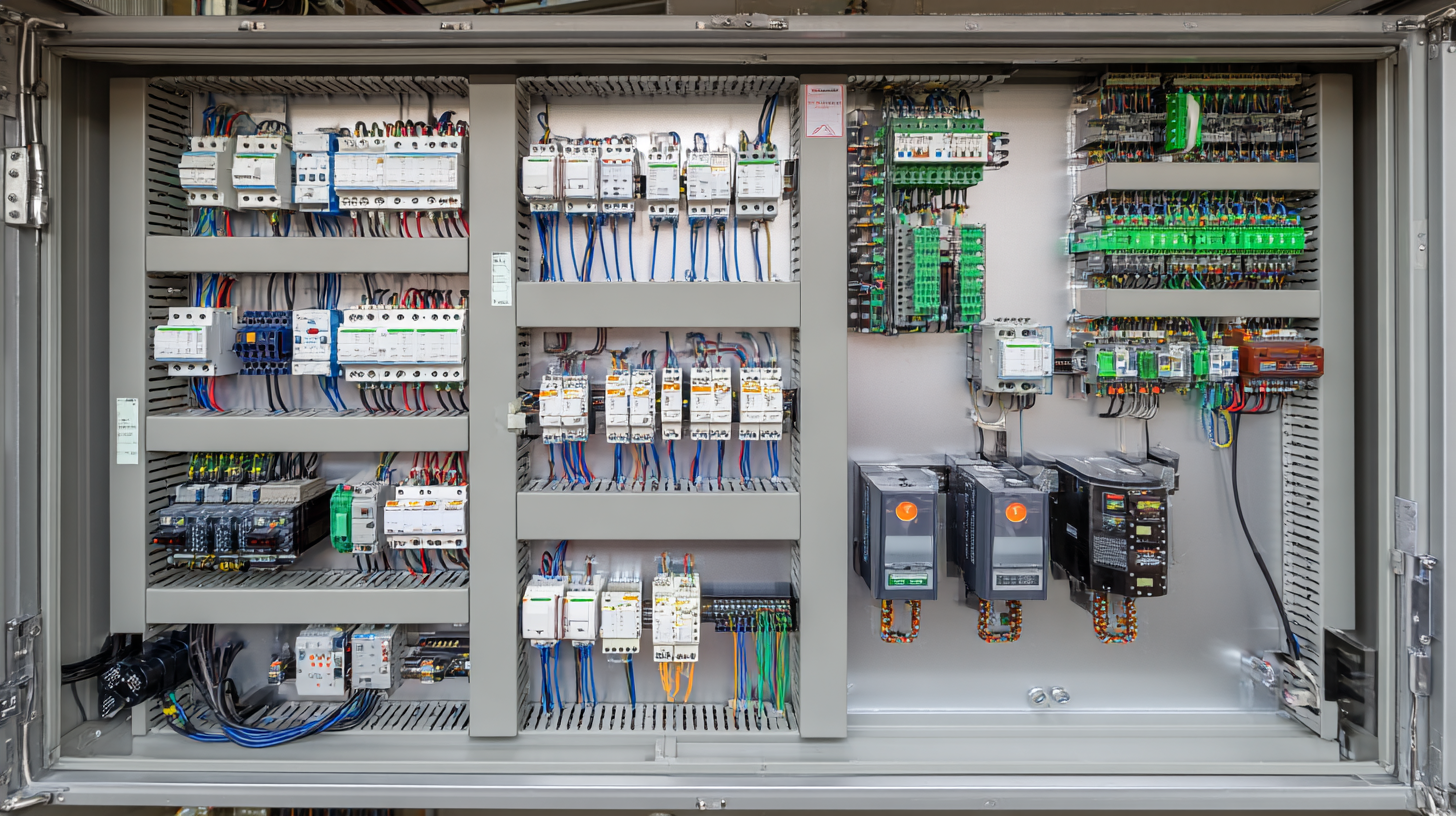

Electrical control panels play a crucial role in enhancing operational efficiency across various industries. They serve as the central hub for distributing electrical power and controlling machinery, ensuring that all components operate harmoniously. By optimizing the design of these panels, businesses can minimize downtime and reduce the likelihood of equipment failure, leading to smoother operational flows. Efficient control panels incorporate advanced technologies, such as programmable logic controllers (PLCs), which allow for real-time monitoring and automated adjustments, thus improving overall system responsiveness.

Moreover, the safety aspect of electrical control panels cannot be overlooked. Proper design minimizes the risk of electrical hazards, ensuring that operators can safely interact with equipment. Features such as clear labeling, adequate ventilation, and reliable circuit protection mechanisms contribute to a safer working environment. Understanding the delicate balance between efficiency and safety in electrical control panels ultimately fosters not just productivity but also enhances compliance with industry standards and regulations. This proactive approach to design is essential in maintaining both operational excellence and workplace safety.

Key Design Principles for Enhancing Safety in Electrical Control Panels

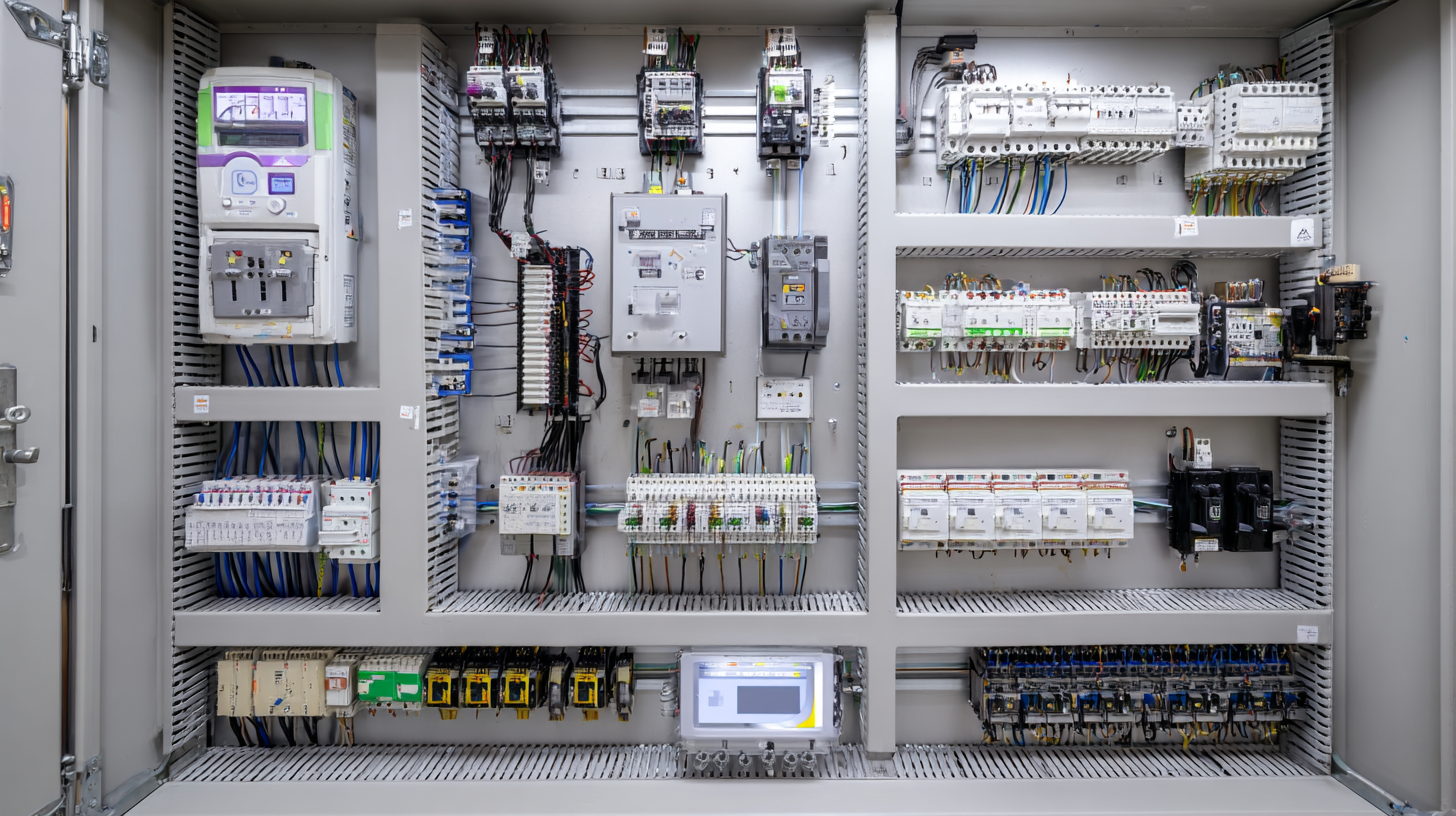

When designing electrical control panels, ensuring safety is paramount. Proper layout and component selection can significantly reduce risks associated with electrical hazards. According to industry standards, control panels must adhere to guidelines set by organizations such as the NATIONAL ELECTRICAL MANUFACTURERS ASSOCIATION (NEMA) and the INSTITUTE OF ELECTRICAL AND ELECTRONICS ENGINEERS (IEEE). By implementing these standards, designers can enhance the safety and efficiency of their control panels.

Tip: Always prioritize the use of quality components that meet safety certifications. Consider incorporating features such as overload protection, emergency stop buttons, and clear labeling of all controls to mitigate risks.

In addition, thermal management is critical in maintaining the functionality of electrical control panels. Implementing cooling systems and ensuring proper ventilation can prevent overheating, which is a leading cause of electrical failures. Industry reports indicate that approximately 30% of electrical faults are due to inadequate cooling.

Tip: Regularly inspect and maintain control panels to identify any signs of wear or overheating. This proactive approach not only prolongs the lifespan of the equipment but also safeguards against potential accidents.

Incorporating Smart Technology to Improve Panel Performance and Monitoring

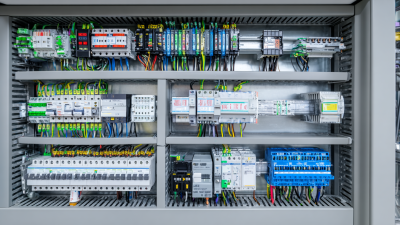

Incorporating smart technology into electrical control panel design is crucial for enhancing both performance and monitoring capabilities. By integrating Internet of Things (IoT) devices and advanced sensors, designers can create systems that provide real-time data feedback and automated alerts. This proactive approach allows for better decision-making by operators and engineers, enabling them to respond swiftly to any anomalies or operational inefficiencies. Moreover, advanced analytics can be employed to predict potential failures, thus minimizing downtime and maintenance costs.

Additionally, smart technology facilitates remote monitoring and control, which greatly improves safety protocols. Using secure cloud-based platforms, operators can access panel data from anywhere, enabling them to make informed adjustments without being physically present. This remote functionality not only safeguards personnel from hazardous environments but also streamlines operations. With enhanced visibility into system performance, organizations can establish more reliable and efficient electrical control panels, leading to improved overall safety and operational efficiency.

How to Optimize Your Electrical Control Panel Design for Maximum Efficiency and Safety - Incorporating Smart Technology to Improve Panel Performance and Monitoring

| Feature | Description | Benefits | Technology Used |

|---|---|---|---|

| Energy Monitoring | Real-time tracking of energy consumption. | Reduces energy costs through awareness and control. | IoT Sensors |

| Remote Monitoring | Access panel status from anywhere. | Improves incident response time and reduces downtime. | Cloud-based Software |

| Automated Alerts | Notifications for system faults and performance issues. | Enhances safety and maintenance scheduling. | Smart Alarm Systems |

| Load Management | Optimization of power distribution to minimize overloads. | Improves reliability and extends equipment lifespan. | Smart Grid Technology |

| User-Friendly Interfaces | Intuitive control panels for ease of operation. | Facilitates user interaction and training. | Touchscreen Displays |

Utilizing Industry Standards for Compliance and Best Practices in Design

When designing electrical control panels, adherence to industry standards is crucial for ensuring both compliance and optimal performance. According to a report by the National Electrical Manufacturers Association (NEMA), non-compliance with established standards can lead to system failures and increased operational risks, emphasizing the importance of integrating protocols such as the National Electrical Code (NEC) and the International Electrotechnical Commission (IEC) guidelines. These standards not only streamlining design processes but also contribute to the longevity and reliability of the control panels.

In addition to regulatory compliance, employing best practices in design can enhance the panel's efficiency and safety. The North American Electric Reliability Corporation (NERC) recommends incorporating features like surge protection devices and proper labeling of components to minimize the risk of electrical faults. Furthermore, utilizing advanced thermal management techniques can improve energy efficiency by reducing heat build-up within the panel, as demonstrated in a study published in the Electrical Engineering Journal, which reported up to a 20% reduction in energy consumption in optimally designed systems. By aligning design practices with industry standards and best practices, electrical control panels can operate at peak efficiency while maintaining the highest safety levels.

Analyzing Energy Consumption and Load Management for Optimal Control Panel Efficiency

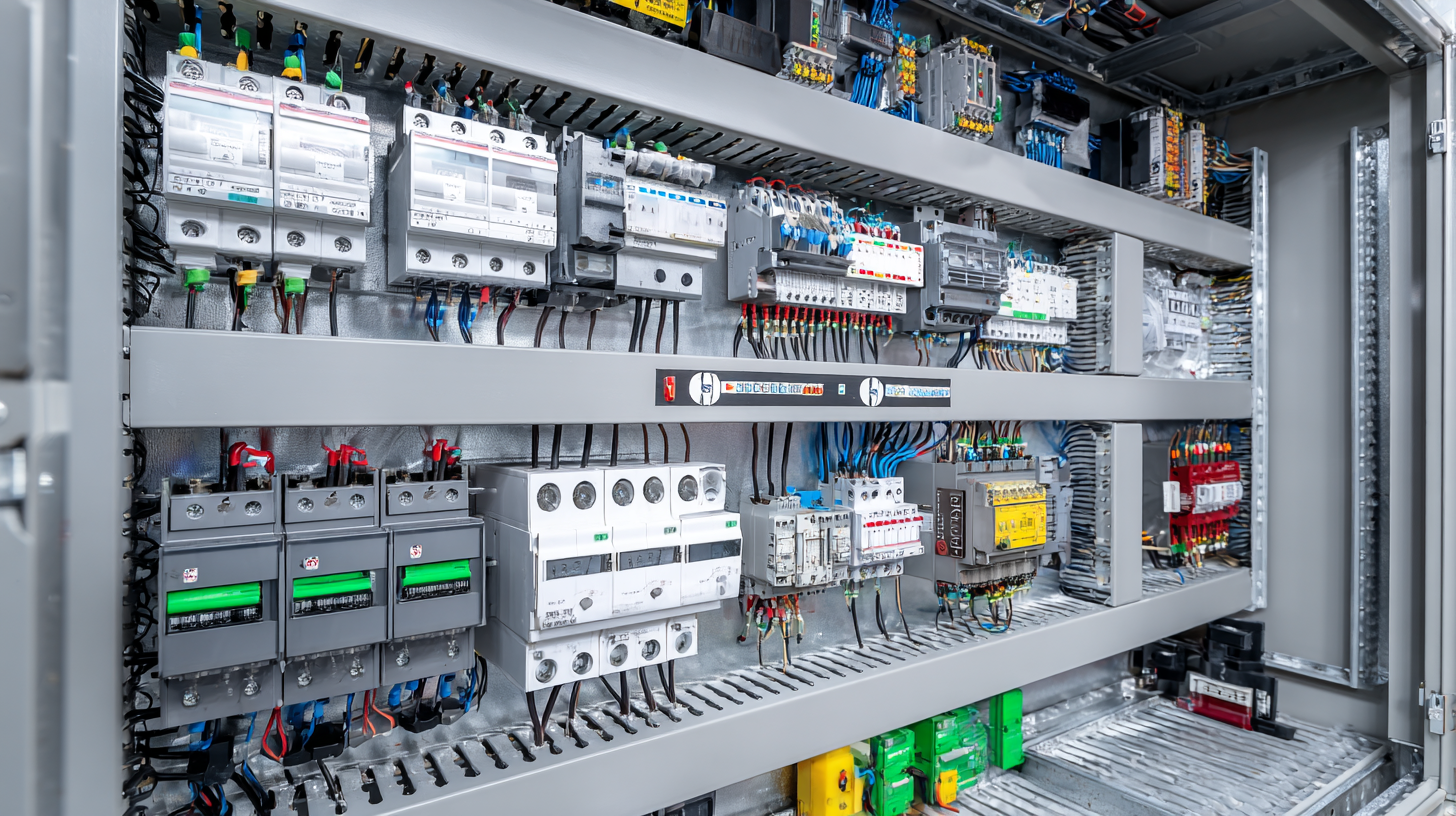

To achieve optimal control panel efficiency, it is essential to analyze energy consumption and load management thoroughly. Understanding the electrical load requirements of your system is crucial for designing a control panel that meets these demands while minimizing energy waste. By conducting an accurate assessment of the loads—taking into account peak usage times and the dynamic nature of the electrical demands—designers can select appropriate components that will operate effectively without overloading. This not only enhances efficiency but also prolongs the lifespan of the equipment.

In addition to evaluating load requirements, implementing effective load management strategies can significantly improve the performance of electrical control panels. Techniques such as demand response can help in balancing the energy consumption during peak times by modulating the load according to availability and pricing incentives. Integrating monitoring systems into the control panel allows for real-time analysis and adjustment of load conditions, ensuring maximum efficiency and safety. With careful consideration of energy use and strategic load management, control panel designs can be optimized to achieve both high performance and safety standards.

Energy Consumption and Load Management Analysis

This chart illustrates the energy consumption and load management for electrical control panels, highlighting the importance of optimizing designs for maximum efficiency and safety. The data represents average energy consumption (in kWh) across various load levels.

Related Posts

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency

-

How to Master Electrical Control Panel Design for Your Next Project

-

7 Best Electrical Power Distribution Panel Features to Maximize Efficiency in Your Facility

-

How to Optimize Your Manufacturing Efficiency with VFD Control Panels

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

10 Essential Tips for Maximizing Your HMI Panel Performance