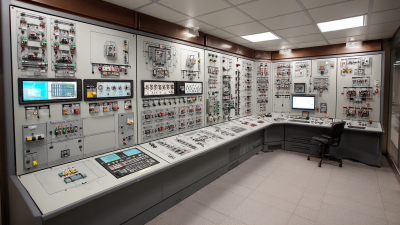

How to Optimize HMI Control Panels for Enhanced Industrial Efficiency and Performance

In today's competitive industrial landscape, optimizing HMI control panels has become crucial for enhancing operational efficiency and performance. A recent report from the International Society of Automation (ISA) highlights that companies can improve productivity by up to 20% through effective HMI design and functionality. As these control panels serve as the vital interface between operators and machinery, their configuration directly impacts decision-making speed and error reduction. Moreover, according to a study by ARC Advisory Group, poorly designed interfaces can lead to significant downtime, costing industries an average of $10,000 per hour. Therefore, implementing best practices in HMI control panel design not only streamlines operations but also contributes to overall cost-effectiveness, making it an essential focus for manufacturers aiming to stay ahead in a rapidly evolving market.

Strategies for Selecting the Right HMI Technology to Boost Operational Efficiency

Selecting the right HMI technology is crucial for enhancing operational efficiency in industrial environments. According to a report by MarketsandMarkets, the HMI market is projected to grow from USD 4 billion in 2020 to USD 6 billion by 2025, signifying the increasing reliance on advanced control interfaces. A well-chosen HMI can streamline communication between operators and machines, reducing response time and minimizing errors, which are pivotal in optimizing production lines.

Tips for selecting the right HMI technology include evaluating your specific automation needs and understanding the user interface that operators will interact with daily. For instance, touch screens with intuitive layouts can decrease training time by up to 30%, significantly improving productivity. Additionally, consider the scalability of the HMI solutions; a versatile system can evolve alongside your business needs, keeping downtime minimal when upgrades are necessary.

Furthermore, investing in HMIs with robust data analytics capabilities can provide real-time insights, driving continuous improvement. Research from Frost & Sullivan highlights that manufacturers who implement advanced data-driven HMIs see an increase in overall efficiency by up to 20%. Integrating such technology not only enhances performance but aligns operations with Industry 4.0 objectives, positioning organizations for long-term success in competitive markets.

Integrating Real-Time Data Analytics in HMI for Improved Decision-Making Processes

Integrating real-time data analytics into HMI (Human-Machine Interface) control panels is a pivotal strategy for enhancing decision-making processes in industrial settings. According to a report by MarketsandMarkets, the global industrial analytics market is projected to reach $190 billion by 2025, driven by the increasing demand for data-driven insights. By embedding robust data analytics capabilities within HMIs, organizations can transition from reactive to proactive decision-making, thereby improving operational efficiency. Real-time analytics facilitate quick identification of anomalies and performance metrics, allowing operators to make informed decisions rapidly.

Furthermore, research from McKinsey indicates that companies implementing advanced analytics in their operations can improve productivity by up to 20-30%. This improvement is largely attributed to the enhanced visibility and understanding of complex processes made possible by real-time data. For instance, integrating predictive maintenance algorithms within HMI systems can significantly reduce downtime and maintenance costs, aligning with the manufacturing industry's push towards smart technologies. Thus, the strategic incorporation of real-time data analytics in HMI systems not only fosters better operational transparency but also empowers teams to leverage data for optimizing performance outcomes effectively.

Design Principles for User-Friendly HMI Interfaces that Minimize Operator Error

In the realm of industrial automation, Human-Machine Interfaces (HMIs) play a vital role in ensuring that operators can interact with complex systems efficiently and accurately. Designing user-friendly HMI interfaces is essential for minimizing operator error, which can lead to costly downtime and safety risks. Focusing on clarity and simplicity in design can significantly enhance the user experience, enabling operators to make quick decisions in critical situations.

Tips: To create effective HMI interfaces, prioritize the use of clear labels and intuitive symbols. Ensure that operators can recognize functions and information at a glance. Implement color-coding to convey status quickly—green for operational, yellow for warnings, and red for alerts. Furthermore, minimize the number of steps required to access critical functions to reduce the chance of mistakes.

Another vital design principle is to incorporate feedback mechanisms. Operators should receive immediate visual or auditory feedback upon interaction, confirming their actions and assisting in error prevention. Regular usability testing is crucial; gather input from actual operators to assess interface effectiveness and make necessary adjustments. By integrating these principles, organizations can boost industrial efficiency and enhance overall performance through their HMI control panels.

Implementing Predictive Maintenance Techniques through HMI Systems for Cost Reduction

In the ever-evolving landscape of industrial operations, implementing predictive maintenance techniques via Human-Machine Interface (HMI) systems can significantly enhance efficiency and reduce operational costs. According to a recent report by McKinsey, predictive maintenance can lead to a 20-25% reduction in maintenance costs and a 30% increase in equipment lifespan. By utilizing data analytics within HMI systems, operators can identify potential equipment failures before they occur, allowing for timely interventions that minimize downtime and extend the longevity of assets.

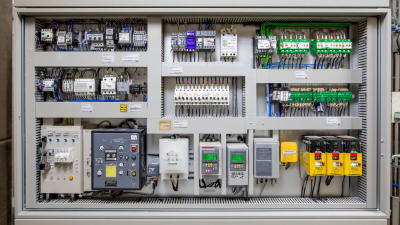

Integrating advanced sensors and IoT capabilities into HMI panels not only facilitates real-time monitoring of machinery but also enables the application of machine learning algorithms to predict maintenance needs. A 2021 study by Deloitte highlighted that organizations applying predictive maintenance techniques experienced a remarkable 10-15% increase in overall equipment effectiveness (OEE). By seamlessly visualizing operational data through user-friendly HMI interfaces, industrial operators can make informed decisions, ultimately leading to improved performance and reduced costs.

Embracing these strategies places manufacturers at the forefront of efficiency, empowering them to adapt to market demands while maintaining a competitive edge.

Enhancing HMI Connectivity with IoT to Streamline Industrial Operations and Performance

The integration of IoT technology into Human-Machine Interface (HMI) control panels is revolutionizing industrial operations. By enhancing HMI connectivity with IoT, businesses can achieve real-time data monitoring and improved communication between machinery and operators. This leads to more responsive systems that can adapt swiftly to changes in operational conditions, ultimately boosting efficiency and performance.

**Tips:** To optimize HMI connectivity with IoT, start by selecting IoT-enabled devices that seamlessly integrate with your existing systems. Regularly update your software to ensure compatibility and security, allowing for smoother data transmission and less downtime. Additionally, consider implementing cloud-based solutions, which can facilitate remote access and control, making it easier to monitor operations from anywhere.

Moreover, enhancing HMI design with user-friendly interfaces ensures that operators can quickly interpret complex data. Prioritizing clear visualizations, such as dashboards that display real-time analytics, can significantly reduce response times for troubleshooting and decision-making. Always gather feedback from operators to continually refine and improve the HMI experience, ensuring your system remains efficient and effective in a rapidly evolving industrial landscape.

Industrial Efficiency Metrics: HMI Control Panels Optimization

This chart compares the performance metrics of HMI control panels before and after optimization. Key indicators such as response time, error rate, downtime, and production output illustrate the improvements achieved through enhanced connectivity and IoT integration.

Related Posts

-

10 Essential Tips for Maximizing Your HMI Panel Performance

-

The Future of HMI Panel Innovation and Automation

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

7 Essential Tips for Creating the Best Control Panel Drawings in Industrial Automation

-

Mastering Control Engineering 10 Essential Digital Tips for Boosting Efficiency and Reducing Costs