How to Optimize Manufacturing Control Systems for Increased Efficiency and Productivity

In today's competitive manufacturing landscape, optimizing manufacturing control systems has become crucial for businesses aiming to increase efficiency and productivity. These systems serve as the backbone of operational processes, ensuring that resources are effectively utilized and workflows are streamlined. By harnessing advanced technologies and data analytics, organizations can fine-tune their control systems to minimize downtime, reduce waste, and enhance overall performance.

Manufacturing control systems encompass a wide range of tools and methodologies designed to monitor, manage, and improve production processes. As industries continue to evolve and face new challenges, it is essential to adapt these systems to align with organizational goals and market demands. Understanding the key components and best practices for optimizing these systems can ultimately lead to substantial gains in productivity, allowing companies to remain agile and responsive in an ever-changing environment.

In this discussion, we will explore various strategies for optimizing manufacturing control systems, focusing on the integration of technology, the importance of real-time data analysis, and fostering a culture of continuous improvement. By implementing these approaches, manufacturers can not only enhance their operational efficiency but also create a sustainable competitive advantage in the marketplace.

Understanding Manufacturing Control Systems and Their Importance

Manufacturing control systems play a critical role in enhancing the efficiency and productivity of production processes. These systems facilitate the automation of manufacturing operations, enabling real-time monitoring, data collection, and process adjustments. According to a report by McKinsey & Company, companies that effectively implement digital manufacturing systems can boost productivity by as much as 20-25%. This is achieved through optimized workflow management, improved resource allocation, and minimized downtime, all of which contribute to a more agile production environment.

Additionally, the importance of manufacturing control systems is underscored by their ability to provide valuable insights into operational performance. A study by Deloitte indicates that manufacturers utilizing advanced analytics and real-time data can achieve operational efficiencies that outpace their competitors by 14%. By harnessing data from various stages of the manufacturing process, organizations can identify bottlenecks, predict equipment failures, and ultimately refine their production strategies. Such proactive measures not only enhance product quality but also lead to significant cost savings and improved customer satisfaction in a highly competitive marketplace.

How to Optimize Manufacturing Control Systems for Increased Efficiency and Productivity

| Dimension | Current Status | Target Status | Improvement Actions |

|---|---|---|---|

| Production Cycle Time | 120 minutes | 90 minutes | Implement Lean Manufacturing principles |

| Defect Rate | 5% | 2% | Increase quality control checks |

| Machine Utilization | 70% | 85% | Schedule regular maintenance |

| Inventory Turnover | 5 times/year | 8 times/year | Adopt Just-In-Time inventory |

| Employee Training Hours | 10 hours/year | 20 hours/year | Enhance training programs |

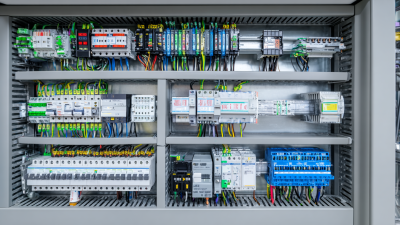

Key Components of Efficient Manufacturing Control Systems

Efficient manufacturing control systems are integral to boosting productivity and streamlining operations. Key components of these systems include real-time data analytics, automated workflows, and integrated supply chain management. According to a report by the International Society of Automation, companies that implement real-time data analytics can improve their operational efficiency by up to 40%. This is largely due to the immediate insights provided on production processes, allowing for timely decision-making and reducing downtime.

Another vital element is the automation of workflows, which helps minimize human error and increases speed. Research from the McKinsey Global Institute indicates that automating certain manufacturing functions can boost productivity by as much as 25%. This underscores the importance of adopting automation to not only enhance efficiency but also to redeploy human resources to more strategic tasks.

**Tip:** Regularly assess your manufacturing control system for bottlenecks and inefficiencies. Implementing advanced software that provides predictive maintenance alerts can significantly reduce unexpected machine failures, ensuring a smoother production flow.

Moreover, integrating supply chain management into the manufacturing control system ensures better coordination between suppliers and production schedules. A study by Deloitte found that businesses with integrated supply chains see a 15% improvement in inventory levels and an 18% reduction in operational costs. The synergy between these components ultimately leads to a more agile manufacturing environment that can quickly adapt to market demands.

Strategies for Data Analysis and Real-time Monitoring

In the quest to enhance manufacturing control systems, harnessing the power of data analysis and real-time monitoring is essential. The implementation of robust data analytics allows manufacturers to identify inefficiencies and bottlenecks within production processes. By employing advanced statistical techniques and machine learning algorithms, organizations can analyze large datasets generated in real-time. This enables predictive maintenance, where potential issues are identified before they lead to equipment failures, thus minimizing downtime and maintaining smooth operations.

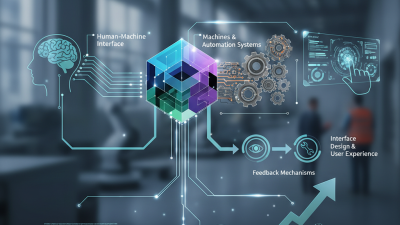

Real-time monitoring plays a crucial role in providing visibility into manufacturing processes, enabling swift decision-making and corrective actions. By integrating IoT devices and sensors, companies can gather continuous data on key performance indicators (KPIs), including production speed, quality metrics, and equipment health. This instantaneous feedback allows for dynamic adjustments to the manufacturing process, optimizing workflows and resource allocation. Furthermore, real-time dashboards can facilitate effective communication among teams, ensuring that everyone is aligned on production goals and responsive to changes in demand or process variations.

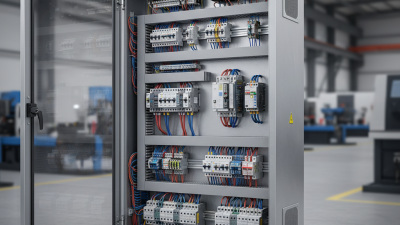

Implementing Automation and Technology in Control Systems

Implementing automation and technology in manufacturing control systems is essential for enhancing efficiency and productivity. By integrating advanced automation tools, manufacturers can streamline processes, reduce human error, and enable real-time monitoring of production lines. This not only minimizes downtime but also allows for quick adjustments to be made, ensuring optimal workflow and resource utilization. Technologies like Internet of Things (IoT) devices facilitate continuous data collection, providing insights that help managers make informed decisions swiftly.

Moreover, the adoption of artificial intelligence and machine learning algorithms in control systems enables predictive maintenance and advanced analytics. These systems can analyze historical data to forecast potential equipment failures, allowing manufacturers to proactively address issues before they disrupt production. Additionally, automation technologies, such as robotics, can handle repetitive tasks with precision, allowing human workers to focus on more complex functions, thus boosting overall output and innovation. By embracing these technological advancements, manufacturers can create a more agile and responsive production environment.

Measuring Performance Indicators for Continuous Improvement

To optimize manufacturing control systems effectively, measuring performance indicators is essential for continuous improvement. Key performance indicators (KPIs) provide insights into various aspects of the manufacturing process, such as production speed, quality rates, and equipment efficiency. By establishing clear KPIs, manufacturers can identify bottlenecks and areas requiring enhancement. For instance, tracking the Overall Equipment Effectiveness (OEE) can reveal not only how much time machinery is operational but also the quality of the output, guiding teams to focus their efforts on critical issues.

In addition to regular monitoring of KPIs, it is crucial to foster a culture of continuous improvement within the organization. This can be achieved by promoting data-driven decision-making and encouraging teams to utilize performance metrics actively. Training employees to understand and act upon these indicators empowers them to contribute to efficiency initiatives. Regularly reviewing performance data allows for timely adjustments in operational strategies, ensuring that the manufacturing control systems evolve in response to both internal challenges and external market demands. By committing to this practice, companies not only streamline their processes but also cultivate a resilient and adaptable manufacturing environment.

Optimizing Manufacturing Control Systems - Performance Indicators

This bar chart represents various performance indicators critical for optimizing manufacturing control systems. The data showcases Production Output, Quality Rate, Downtime, Worker Efficiency, and Scrap Rate, allowing for visual analysis of current performance levels.

Related Posts

-

Revolutionizing Manufacturing Control Systems Insights from the 138th China Import and Export Fair 2025

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

How to Master Panel PLC Programming: Tips and Techniques for Beginners

-

What is HMI Programming and How to Get Started with It

-

10 Essential Tips for Designing an Efficient Electrical Control Panel

-

Unlocking the Secrets of Motor Power Efficiency for Sustainable Energy Solutions