How to Optimize Your PLC Panel for Maximum Efficiency and Performance

In today's manufacturing landscape, the efficiency of programmable logic controllers (PLCs) plays a crucial role in the overall performance of industrial automation systems. A recent report by the International Society of Automation indicated that optimizing PLC panels can improve system reliability and reduce downtime by up to 30%. As industries continue to adopt more complex processes, the importance of an efficiently designed PLC panel cannot be overstated, particularly in terms of energy consumption and operational effectiveness. By implementing best practices for panel layout, component selection, and heat management, organizations can significantly enhance the functionality and lifespan of their PLC systems. In this guide, we will explore actionable strategies to maximize the efficiency and performance of your PLC panel, ensuring seamless integration and robust performance in your automation workflow.

Understanding the Basics of PLC Panels and Their Components

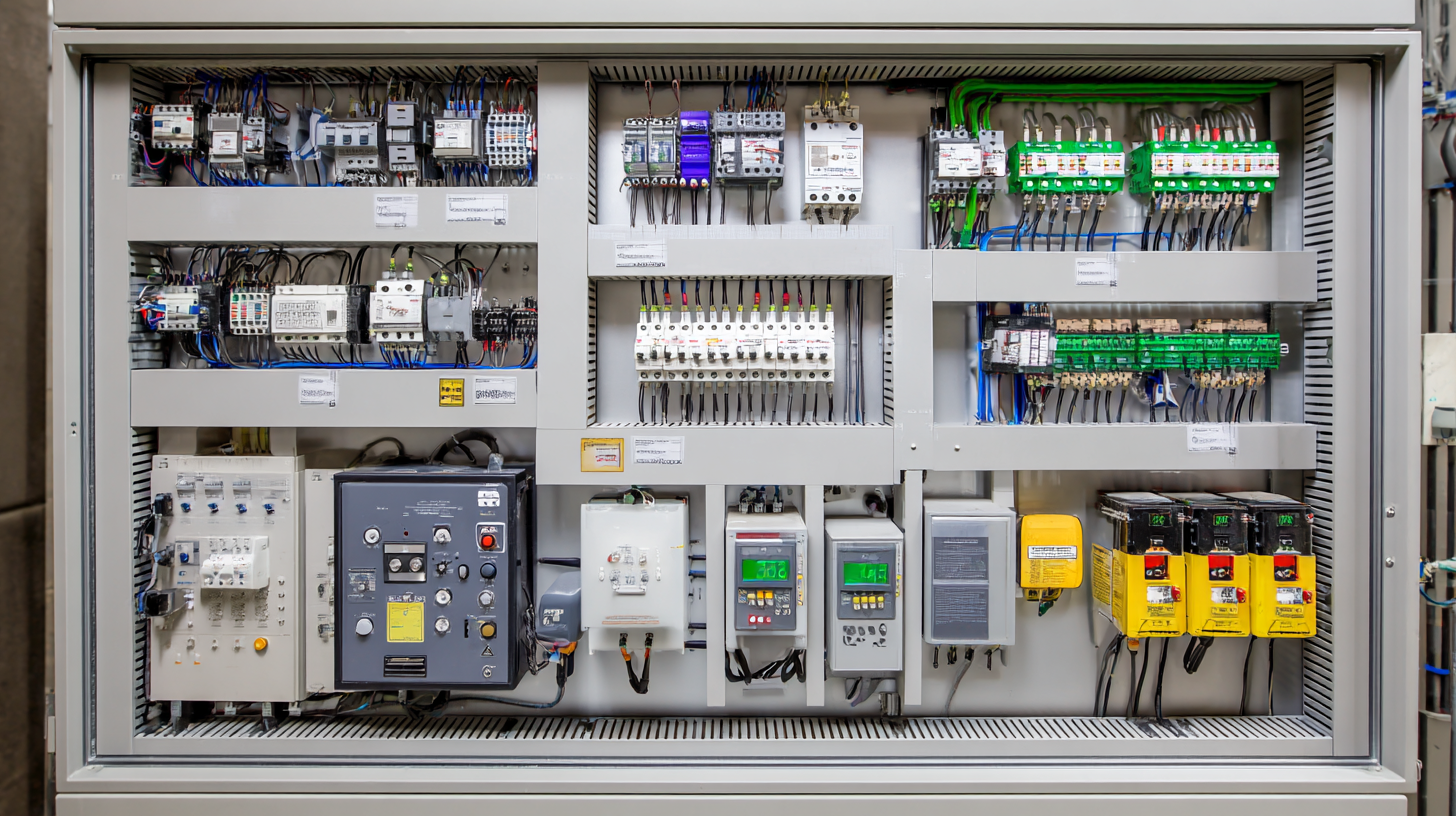

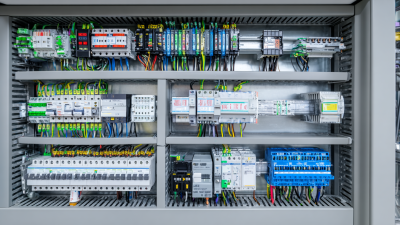

PLC panels are essential in automating industrial processes, and understanding their basic components can greatly enhance operational efficiency. At the core of a PLC panel is the Programmable Logic Controller itself, which serves as the brain of the operation. It processes inputs from various sensors, executes programmed instructions, and then sends commands to output devices. Alongside the PLC, components such as power supplies, input/output modules, and safety relays are crucial for ensuring the reliability and performance of the panel.

Recent trends in the industry indicate a shift from traditional rack-mounted control systems towards more compact and integrated solutions. As OEMs (Original Equipment Manufacturers) embrace this change, the design and layout of PLC panels become increasingly important. The focus is on reducing wiring complexity, which not only simplifies installation but also enhances maintenance and troubleshooting. A well-designed panel minimizes clutter and encourages efficiency, allowing operators to concentrate on their tasks without the distraction of tangled wires. Furthermore, the integration of smart technologies and automation solutions is driving innovation within PLC systems, further optimizing the way energy management and control processes are handled in industrial settings.

Analyzing Common Performance Issues in PLC Systems

One of the predominant challenges in optimizing PLC (Programmable Logic Controller) systems is identifying and addressing common performance issues that can lead to inefficiencies. According to the International Society of Automation (ISA), nearly 40% of automation failures are attributed to misconfigured PLC settings. This highlights the critical importance of proper configuration and regular maintenance to mitigate risks and enhance system performance.

Latency in communication and processing times is another frequent issue. A study conducted by the Automation Federation found that 30% of industrial operations report excess latency as a major barrier to achieving real-time control and monitoring. By analyzing and optimizing communication protocols and network architecture, industries can significantly reduce these latencies and improve overall system responsiveness. Furthermore, regular diagnostics and software updates can help in identifying bottlenecks early, ensuring that PLC systems operate at their peak efficiency.

Lastly, many PLC systems suffer from inadequate power management, which can lead to unexpected downtime. According to a report by the Energy Department, optimizing power consumption can reduce energy costs by up to 20% in industrial settings. This not only improves performance but also contributes to sustainability initiatives, making it essential for organizations to focus on efficient power management solutions as part of their PLC optimization strategies.

Implementing Best Practices for Efficient Wiring and Layout

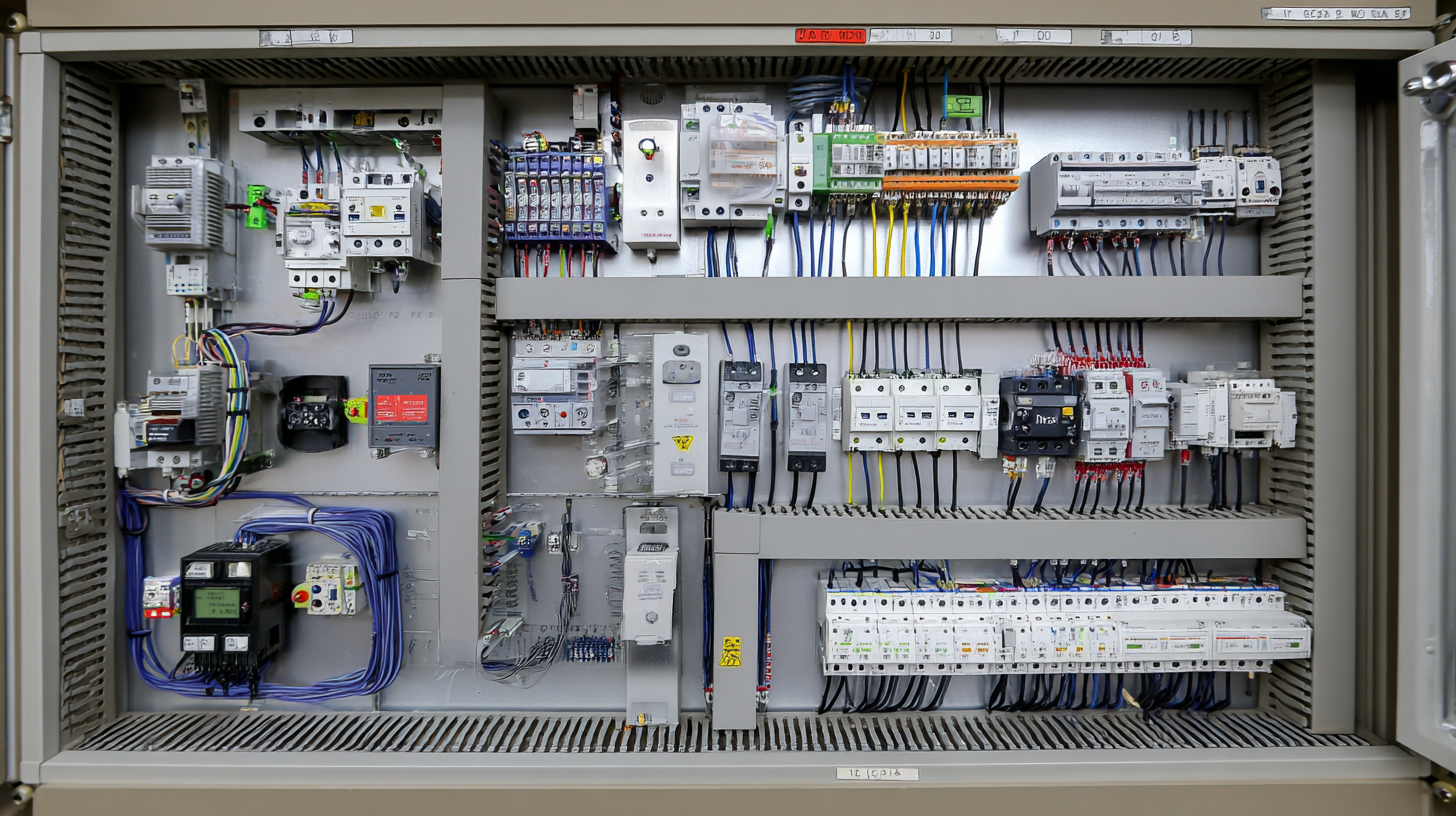

When optimizing a PLC panel for maximum efficiency, the wiring and layout must be approached with a strategic mindset. Efficient wiring not only minimizes clutter but also enhances the reliability of the system. It is essential to use color-coded wires to clearly delineate different functions and to maintain consistency in color use throughout the panel. Additionally, grouping wires logically according to their functions can simplify troubleshooting and maintenance processes. Employing proper wire management techniques, such as cable ties and ducts, can further improve airflow and reduce the risk of electromagnetic interference, which can adversely affect performance.

In terms of layout, it's crucial to arrange components logically, placing frequently accessed elements within easy reach while ensuring that connections are straightforward. Utilizing a modular design can facilitate future expansions or modifications, allowing for quick adjustments as needs evolve. Spacing components adequately helps dissipate heat and prevents overcrowding, which can lead to increased wear and potential failures. By adhering to these best practices, PLC panels can achieve optimal efficiency, providing faster responses and enhancing overall system performance.

Leveraging Software Tools for PLC Optimization

Leveraging software tools for PLC optimization is essential for enhancing the efficiency and performance of programmable logic controllers. According to a recent report by ABI Research, the implementation of advanced software solutions can improve production efficiencies by up to 30%. These tools facilitate real-time monitoring and analysis, enabling operators to identify bottlenecks and optimize workflows within their automation systems. By employing simulation software, businesses can model various scenarios and predict system performance under different conditions, which directly informs maintenance schedules and operational adjustments.

Moreover, integrating data analytics software with PLC systems allows for continuous improvement through the collection and analysis of operational data. A study by MarketsandMarkets indicated that the industrial automation market, which includes PLC optimization software, is expected to reach $214 billion by 2026, highlighting the increasing investment in technologies that drive efficiency. With predictive analytics, companies can foresee potential failures, allowing preemptive measures to reduce downtime and maintain optimal performance. These software tools not only streamline operations but also enhance decision-making processes, positioning organizations for sustained growth and competitiveness in an evolving industry landscape.

Regular Maintenance Strategies for Sustained PLC Performance

Regular maintenance of your PLC (Programmable Logic Controller) panel is essential for ensuring sustained performance and efficiency. According to a study conducted by the ARC Advisory Group, up to 30% of equipment downtime can be attributed to insufficient maintenance practices. Implementing routine inspections can significantly mitigate this issue, allowing potential problems to be identified and addressed before they escalate into costly repairs or unplanned downtime.

One effective strategy is to establish a regular cleaning schedule for your PLC components. Dust and debris can impede the function of electrical connections and cooling systems, leading to overheating and malfunction. A report from the International Society of Automation emphasizes that keeping the control panel free from contaminants can enhance equipment longevity by up to 40%. Additionally, regularly updating software and firmware not only boosts performance but also enhances security, given that cybersecurity threats in industrial settings are on the rise. By prioritizing these maintenance strategies, organizations can optimize their PLC panels for not only immediate operational efficiencies but also long-term performance stability.

How to Optimize Your PLC Panel for Maximum Efficiency and Performance - Regular Maintenance Strategies for Sustained PLC Performance

| Maintenance Strategy | Frequency | Expected Impact | Estimated Time (Hours) |

|---|---|---|---|

| Visual Inspection | Monthly | Early detection of issues | 1 |

| Cleaning of Components | Quarterly | Improved air circulation | 2 |

| Firmware Updates | Biannually | Enhanced features and security | 3 |

| Cable and Connector Check | Annually | Prevention of electrical faults | 2 |

| Testing Input/Output Devices | Semi-annually | Ensured operational reliability | 2.5 |

Related Posts

-

What is the Importance of PLC Programming in Modern Automation

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

What is Control Engineering and Why It Matters in Modern Industry

-

How to Optimize Your Manufacturing Efficiency with VFD Control Panels

-

How to Master Electrical Control Panel Design for Your Next Project

-

Mastering Control Engineering 10 Essential Digital Tips for Boosting Efficiency and Reducing Costs