Understanding PLC Control Panels: Essential Components and Their Impact on Automation Efficiency

In the realm of industrial automation, the PLC control panel is a pivotal component that directly influences operational efficiency and system reliability. According to a recent report by the International Society of Automation, over 75% of manufacturing processes now leverage programmable logic controllers (PLCs) to enhance automation capabilities. These control panels serve as the brain of automation systems, integrating various hardware and software elements to manage machinery and processes efficiently.

As industries strive for smarter, more agile production environments, understanding the essential components of PLC control panels becomes crucial. An effective design not only improves performance but also reduces downtime, leading to significant cost savings and improved return on investment. Thus, grasping the intricacies of PLC control panels is vital for organizations aiming to stay competitive in an ever-evolving market landscape.

Key Components of PLC Control Panels: A Breakdown

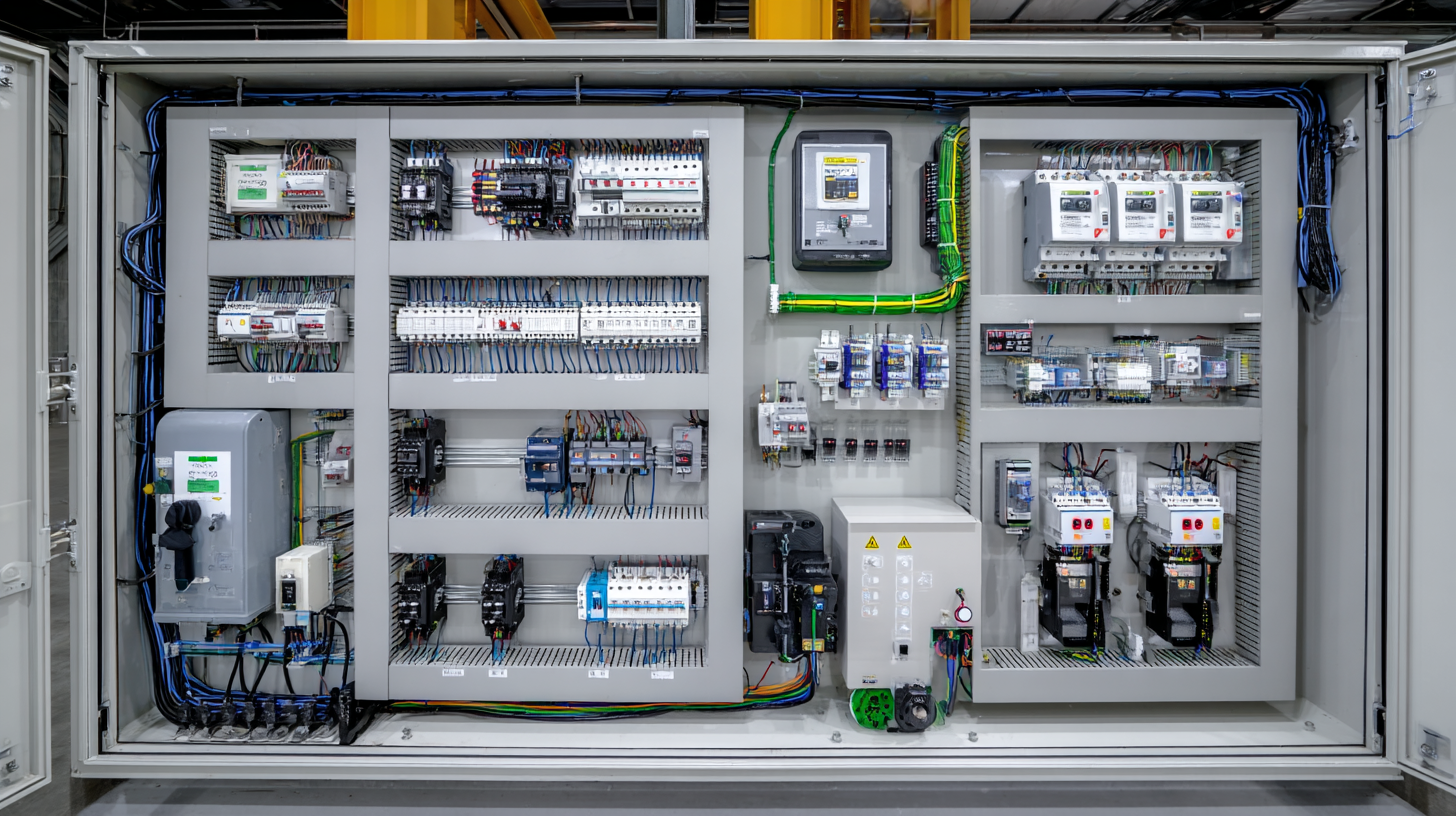

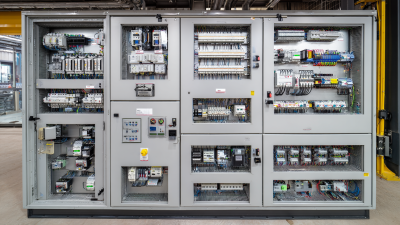

PLC (Programmable Logic Controller) control panels are integral to modern automation processes, significantly enhancing operational efficiency across various industries. Understanding the key components of these panels can help in maximizing the benefits they bring. A typical PLC control panel comprises several critical elements, including the PLC itself, input/output devices, power supplies, and communication networks. Each component plays a pivotal role; for instance, the PLC processes inputs from sensors and sends commands to actuators, ensuring seamless operations.

PLC (Programmable Logic Controller) control panels are integral to modern automation processes, significantly enhancing operational efficiency across various industries. Understanding the key components of these panels can help in maximizing the benefits they bring. A typical PLC control panel comprises several critical elements, including the PLC itself, input/output devices, power supplies, and communication networks. Each component plays a pivotal role; for instance, the PLC processes inputs from sensors and sends commands to actuators, ensuring seamless operations.

According to a recent report by the International Society of Automation (ISA), implementing advanced PLC systems can increase production efficiency by up to 30%. Furthermore, integrating robust communication protocols, such as Ethernet/IP and Modbus, facilitates real-time data exchange, enhancing monitoring and control capabilities.

Tip: When designing a PLC control panel, ensure that the layout is organized and labeled clearly. This not only streamlines troubleshooting but also minimizes downtime during maintenance.

Another essential aspect is the selection of input/output devices. Opting for high-quality I/O modules can significantly reduce signal noise and improve response times, leading to more reliable operations. As highlighted in a 2022 report by MarketsandMarkets, the global PLC market is expected to grow from $10.49 billion in 2021 to $14.33 billion by 2026, underscoring the increasing reliance on these systems for efficient industrial automation.

Tip: Regularly update your PLC software and component firmware to enhance functionality and security, ensuring optimal performance of the control panel while adapting to evolving industry standards.

The Role of PLCs in Modern Automation Systems

Programmable Logic Controllers (PLCs) are at the heart of modern automation systems, enhancing operational efficiency in industries ranging from manufacturing to food processing. According to a report by the International Society of Automation, the global PLC market is projected to reach $15 billion by 2026, driven by the increasing demand for smart automation solutions. The adaptability and longevity of PLCs provide industries with the agility to respond to market changes while maintaining productivity.

To leverage the full potential of PLCs, businesses should integrate them with advanced data analytics and IoT technologies. This synergy not only improves real-time monitoring but also enhances predictive maintenance capabilities, significantly reducing downtime. Research shows that companies employing IoT-enabled PLCs can reduce operational costs by up to 30%.

**Tips:**

1. Ensure regular updates and maintenance for your PLC software to maximize reliability.

2. Consider training your workforce on the latest PLC technologies to enhance operational efficiency.

3. Evaluate the performance of your PLC systems regularly to identify areas for improvement and optimization.

Understanding PLC Control Panels: Essential Components and Their Impact on Automation Efficiency - The Role of PLCs in Modern Automation Systems

| Component | Description | Function | Impact on Efficiency |

|---|---|---|---|

| PLC (Programmable Logic Controller) | A digital computer used for automation of industrial processes. | Automates control of machinery and processes. | Increases operational efficiency and reduces human error. |

| Input Devices | Devices that provide signals to the PLC to indicate status or allow user input. | Detects conditions like temperature, pressure, or position. | Enhances data collection for real-time monitoring. |

| Output Devices | Devices that receive signals from the PLC to perform a task. | Controls actuators, motors, and other machinery. | Facilitates precise control over machinery operations. |

| Human-Machine Interface (HMI) | User interface that allows interaction between operators and machines. | Displays information and allows control of processes. | Improves user experience and operational control. |

| Communication Protocols | Standards that enable communication between devices and PLC. | Facilitates data exchange among different systems. | Enhances integration and scalability of automation systems. |

| Power Supply | Provides necessary power for the PLC and its components. | Ensures stable functioning of electronic devices. | Critical for reliability and uptime of operational systems. |

Impact of Control Panel Design on Efficiency and Reliability

The design of PLC control panels plays a crucial role in influencing both efficiency and reliability in automation systems. A well-structured control panel can streamline operations by enabling easier access to components and enhancing organization. This accessibility allows maintenance personnel to quickly diagnose and address issues, minimizing downtime and ensuring that production processes remain uninterrupted. Moreover, a logical layout of instruments and controls can reduce the chance of operator error, further enhancing the overall efficiency of the system.

Additionally, the choice of materials and components within the control panel can significantly impact reliability. High-quality components are less prone to failure, which not only prolongs the lifespan of the system but also reduces long-term maintenance costs. Effective thermal management and appropriate protection from environmental factors are essential design considerations that contribute to stable performance. Therefore, investing in thoughtful control panel design, including the selection of durable materials and an intuitive layout, is fundamental for maximizing automation efficiency and reliability in various industrial applications.

Common Challenges in PLC Panel Implementation and Solutions

Implementing PLC control panels can significantly enhance automation efficiency, but several common challenges can arise during the process. One major issue is the complexity of integration with existing systems. According to a report by the International Society of Automation, approximately 40% of automation projects face difficulties due to incompatible legacy systems. This challenge can often lead to project delays and increased costs, which may undermine the anticipated benefits of automation.

Another prevalent challenge is the skill gap in personnel. The same study indicates that nearly 60% of companies struggle to find adequately trained staff to manage and maintain PLC systems. To address this issue, organizations should invest in comprehensive training programs that can equip their workforce with the necessary skills to handle PLC technology efficiently. Furthermore, leveraging online resources and partnerships with technology providers can help bridge knowledge gaps and ensure a smoother implementation process.

Lastly, maintenance and troubleshooting can pose significant hurdles once a PLC panel is in operation. Research from the National Electrical Manufacturers Association shows that improper maintenance can lead to equipment failure, which accounts for almost 30% of production downtime in manufacturing facilities. Implementing a regular maintenance schedule and utilizing predictive analytics can help mitigate these risks, thereby enhancing the overall efficiency of automation systems.

Future Trends in PLC Technology and Automation Efficiency

The future of PLC technology and automation efficiency is poised for significant evolution, driven by burgeoning trends in industrial automation. With the global industrial automation market projected to expand from approximately USD 169.82 billion in 2025 to USD 443.54 billion by 2035, at a CAGR of 9.12%, it is clear that flexible and programmable automation will play a pivotal role in reshaping industries. This growth is not merely about increasing numbers; it indicates a profound transformation in how businesses leverage technology to enhance operational efficiency and reduce costs.

Recent trends highlight technology convergence and AI integration as major drivers for IT automation by 2025 and beyond. As industries increasingly adopt AI-driven solutions, the integration of these advanced technologies into PLC systems is likely to enhance decision-making processes and operational agility. Alongside this, the advancement of micro and nano PLCs will cater to more specialized industrial applications, demonstrating the industry's shift towards smarter, more efficient production methodologies.

This momentum suggests that automation will not only streamline operations but also redefine industry standards and practices, laying the groundwork for a fundamentally transformed industrial landscape.

Related Posts

-

5 Automation Panels Innovations You Didn't Know You Needed for Optimal Efficiency

-

How to Master Electrical Control Panel Design for Your Next Project

-

What is the Importance of PLC Programming in Modern Automation

-

Electrical Control Panel Design Innovations: Insights from the 138th China Import and Export Fair 2025

-

Understanding the Role of Automation Control Panels in Modern Industrial Systems

-

Exploring the Evolution of Control Panels: Industry Insights and Future Trends in Automation Technology