Revolutionizing Manufacturing Control Systems Insights from the 138th China Import and Export Fair 2025

The 138th China Import and Export Fair in 2025 marks a pivotal moment for the manufacturing sector, especially in the realm of manufacturing control systems. As businesses increasingly embrace digital transformation, the global manufacturing control systems market is projected to reach approximately $25 billion by 2026, growing at a compound annual growth rate (CAGR) of 8.5% (MarketsandMarkets, 2023). Innovations showcased at this trade fair will highlight cutting-edge technologies that improve operational efficiency, traceability, and quality control.

Moreover, the integration of artificial intelligence and the Internet of Things (IoT) into manufacturing control systems is set to redefine industry standards, enabling real-time data analytics and predictive maintenance. As manufacturers strive to enhance productivity and competitiveness on a global scale, the insights gained from the fair will be invaluable in navigating the rapidly evolving landscape of manufacturing technologies.

Moreover, the integration of artificial intelligence and the Internet of Things (IoT) into manufacturing control systems is set to redefine industry standards, enabling real-time data analytics and predictive maintenance. As manufacturers strive to enhance productivity and competitiveness on a global scale, the insights gained from the fair will be invaluable in navigating the rapidly evolving landscape of manufacturing technologies.

Transforming Industrial Automation: Key Trends from the 138th China Import and Export Fair

The 138th China Import and Export Fair showcases significant advancements in industrial automation, highlighting key trends that are redefining manufacturing practices. As industries increasingly rely on automation, the integration of robotics is at the forefront, with innovative solutions enhancing efficiency and precision in production processes. This shift not only streamlines operations but also responds to the growing demand for safety and quality in products, as evidenced by the notable focus on safety footwear at the fair.

China's commitment to revolutionizing its manufacturing sector is evident through its robust national robotics strategy, which aims to position the country as a global leader in this field. Industry experts emphasize that the rapid development and adoption of robotics technologies are crucial for maintaining competitiveness and advancing industrial capabilities. As manufacturing control systems evolve, businesses must adapt to these trends to leverage the full potential of automation, ensuring they stay ahead in an increasingly dynamic market landscape.

China's commitment to revolutionizing its manufacturing sector is evident through its robust national robotics strategy, which aims to position the country as a global leader in this field. Industry experts emphasize that the rapid development and adoption of robotics technologies are crucial for maintaining competitiveness and advancing industrial capabilities. As manufacturing control systems evolve, businesses must adapt to these trends to leverage the full potential of automation, ensuring they stay ahead in an increasingly dynamic market landscape.

Integrating AI and IoT in Manufacturing Control Systems for Enhanced Efficiency

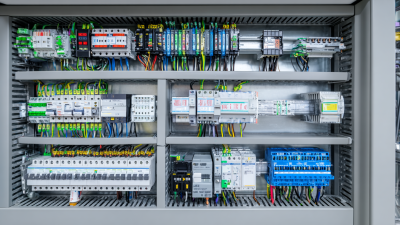

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) in manufacturing control systems signifies a pivotal shift towards enhanced efficiency and productivity. As the manufacturing landscape becomes increasingly competitive, facilities are adopting advanced technologies such as industrial robots, smart sensors, and machine vision systems. These innovations allow for real-time data analysis and automation of processes, ultimately optimizing production and minimizing downtime. As companies continue to embrace Industry 4.0 principles, the market for these sophisticated control systems is projected to grow significantly.

The adoption of AI and IoT not only improves operational efficiency but also drives cost reduction and increases overall output. Manufacturing facilities are now capable of anticipating maintenance needs through predictive analytics, reducing the risk of costly disruptions. The integration of smart solutions creates a connected ecosystem that enables seamless communication between machines and operators, enhancing decision-making and responsiveness. As manufacturers recognize the value of these technologies in streamlining processes, the market for AI and IoT-driven control systems is on a trajectory of robust expansion, reflecting a growing commitment to leveraging innovative tools for manufacturing excellence.

Data-Driven Decision Making: Leveraging Big Data Analytics in Manufacturing Control

As Industry 4.0 continues to evolve, the adoption of advanced analytics in manufacturing is becoming critical. The integration of IoT, AI, and cloud computing is paving the way for new methodologies that leverage big data in real-time decision-making processes. A report by McKinsey indicated that companies utilizing data analytics can improve operational efficiency by up to 20%. This trend is particularly evident in the chlor-alkali sector, where companies are challenged to meet dual pressures of carbon reduction and globalization.

In this landscape, companies such as the innovative pharmaceutical manufacturing base in Shanghai are transforming from traditional manufacturing to intelligent manufacturing. Utilizing AI-driven insights, they are not only enhancing production efficiency but also addressing significant energy consumption and safety requirements. As reported by Deloitte, up to 70% of manufacturers are investing in AI technologies to streamline operations and reduce costs.

**Tip:** To seamlessly integrate big data into your operational framework, start small—experiment with pilot projects that test real-time data applications. Also, ensure your workforce is trained on these new technologies to maximize the potential of your data investments. Furthermore, consider forming strategic partnerships with technology providers to stay at the forefront of Industry 4.0 advancements.

Revolutionizing Manufacturing Control Systems Insights from the 138th China Import and Export Fair 2025

| Manufacturing Sector | Current Challenges | Data Analytics Application | Expected Outcomes |

|---|---|---|---|

| Automotive Manufacturing | High production costs, quality control | Predictive maintenance using IoT data | Reduced downtime, lower costs |

| Electronics Manufacturing | Supply chain disruptions | Supply chain optimization analytics | Enhanced efficiency, reduced lead times |

| Food Processing | Regulatory compliance, waste management | Real-time quality monitoring | Improved safety, reduced waste |

| Textile Industry | Labor shortages, inventory issues | Inventory management analytics | Optimized inventory levels, cost savings |

| Chemical Manufacturing | Environmental regulations | Emission tracking analytics | Regulatory compliance, improved sustainability |

Sustainable Manufacturing Solutions: Innovations Presented at the 138th Fair

The 138th China Import and Export Fair 2025 highlighted significant advancements in sustainable manufacturing solutions, showcasing innovations that can reshape the industry. With a growing emphasis on environmental responsibility, manufacturers are prioritizing technologies that reduce waste and enhance energy efficiency. According to a recent report by the McKinsey Global Institute, the adoption of sustainable practices in manufacturing can lead to a 30% reduction in operational costs while increasing resource productivity by 50%. This paradigm shift not only benefits manufacturers but also aligns with global sustainability goals.

Amidst this backdrop, emerging technologies such as AI-driven automation and renewable energy systems took center stage at the fair. These innovations serve dual purposes: optimizing production processes while minimizing environmental impact. For instance, companies that adopt smart manufacturing technologies are projected to see an upsurge in productivity by up to 25% by 2030, as noted in the The World Economic Forum's recent study. Staying ahead of these trends is essential for manufacturers looking to enhance their competitive edge.

Tips: Consider investing in energy-efficient machinery and training your workforce on sustainable practices. Additionally, collaborating with technology providers can streamline the transition to smarter, more sustainable manufacturing processes. Adopting these practices not only ensures compliance with regulations but also positions your business as a leader in the sustainability movement.

Emerging Technologies in Robotics: Shaping the Future of Manufacturing Control Systems

The 138th China Import and Export Fair in 2025 showcased a myriad of innovations in manufacturing control systems, with a particular emphasis on emerging technologies in robotics. As industries increasingly leverage automation, advanced robotics is becoming a cornerstone in revolutionizing manufacturing processes. These intelligent machines not only enhance efficiency but also significantly improve precision in production lines, allowing for real-time adjustments and error corrections that were once unattainable.

The integration of artificial intelligence and machine learning into robotic systems is shaping the future of manufacturing control. With these technologies, robots can analyze vast amounts of data to optimize operations and predict maintenance needs, reducing downtime. Moreover, collaborative robots, or cobots, are designed to work alongside human operators, enhancing flexibility and safety in manufacturing environments. This synergy between human workers and robotic systems represents a significant shift, fostering a more adaptive manufacturing landscape prepared for future challenges.

Emerging Technologies in Robotics: Shaping the Future of Manufacturing Control Systems

Related Posts

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

How to Optimize HMI Control Panels for Enhanced Industrial Efficiency and Performance

-

7 Best Electrical Power Distribution Panel Features to Maximize Efficiency in Your Facility

-

5 Automation Panels Innovations You Didn't Know You Needed for Optimal Efficiency

-

How to Optimize Your HMI Control Panel for Enhanced User Experience

-

What is Control Engineering and Why It Matters in Modern Industry