Understanding the Role of Automation Control Panels in Modern Industrial Systems

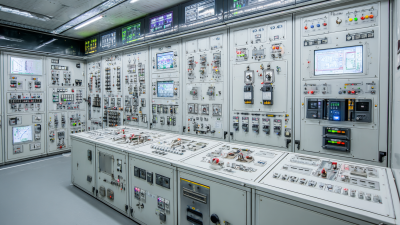

In today's rapidly evolving industrial landscape, the integration of technology has become paramount for optimizing operational efficiency. Among the pivotal components within modern industrial systems is the automation control panel, which serves as the nerve center for process management and control. According to a report by Research and Markets, the global industrial automation market is projected to reach $285 billion by 2027, driven significantly by advancements in automation control solutions. These panels not only enhance reliability and safety but also facilitate real-time monitoring and data analysis, critical for informed decision-making. With increasing adoption rates, driven by the demand for smart manufacturing and Industry 4.0, the role of automation control panels is more crucial than ever in enhancing productivity and reducing downtime across various sectors.

The Importance of Automation Control Panels in Enhancing Operational Efficiency

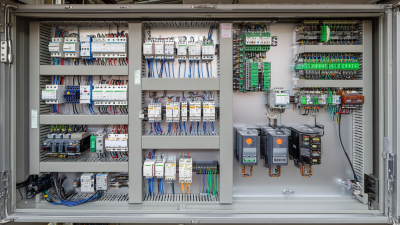

Automation control panels play a crucial role in modern industrial systems by streamlining processes and enhancing operational efficiency. These panels serve as the central point for managing various automated functions, including monitoring machinery, controlling production lines, and ensuring safety protocols are followed. By leveraging advanced technologies, businesses can optimize their operations, leading to reduced downtime and improved productivity.

Automation control panels play a crucial role in modern industrial systems by streamlining processes and enhancing operational efficiency. These panels serve as the central point for managing various automated functions, including monitoring machinery, controlling production lines, and ensuring safety protocols are followed. By leveraging advanced technologies, businesses can optimize their operations, leading to reduced downtime and improved productivity.

Tips for Improving Operational Efficiency with Automation Control Panels:

- Regularly update software to leverage the latest features and security enhancements.

- Train staff on the functionalities of control panels to maximize their utility and encourage proactive maintenance.

- Implement data analytics tools to monitor performance and identify areas for improvement, allowing for informed decision-making.

By integrating automation control panels effectively, organizations can not only enhance efficiency but also adapt more swiftly to changing market demands. With the right strategies in place, the potential for increased profitability and sustainable growth is significant.

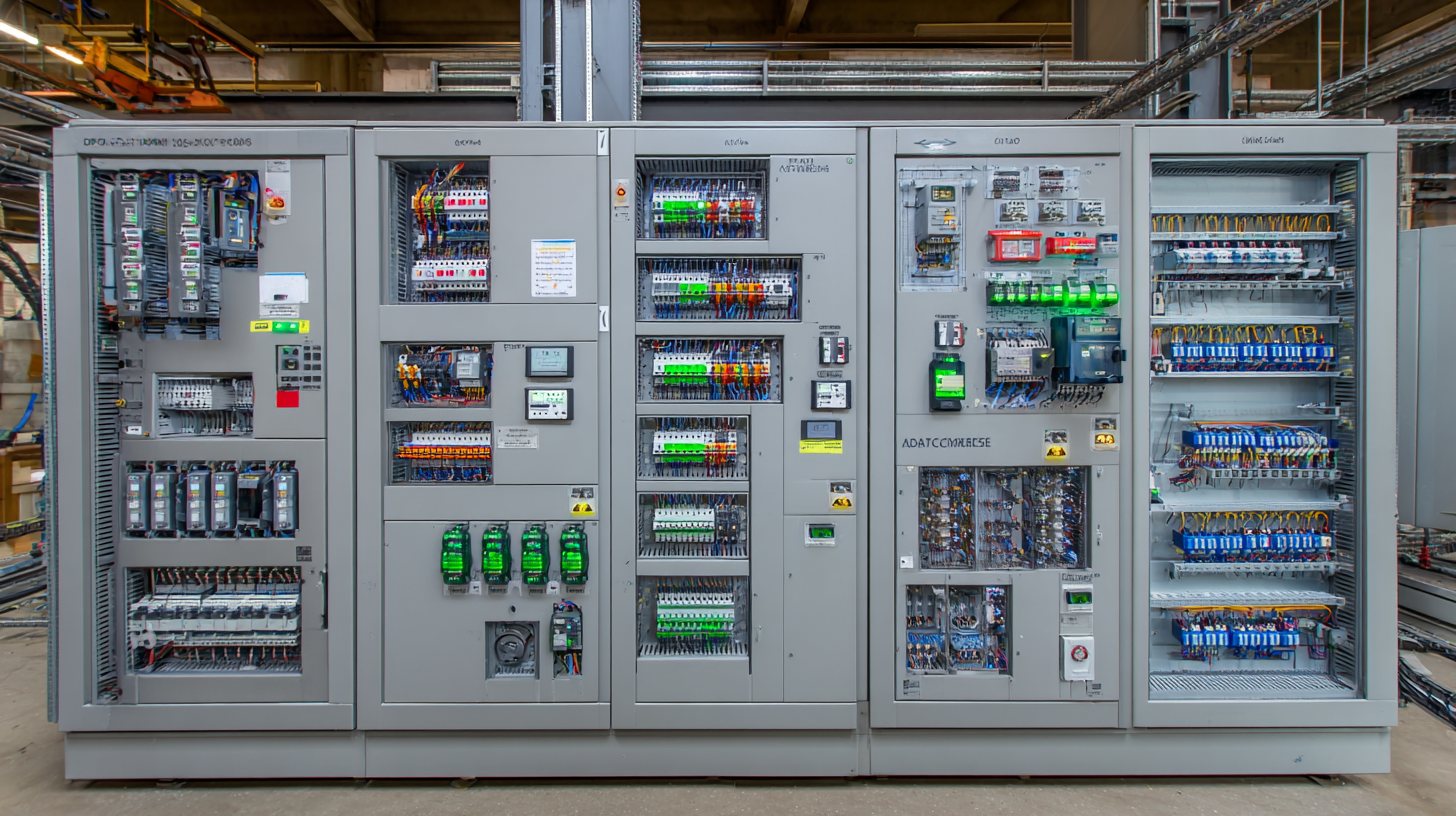

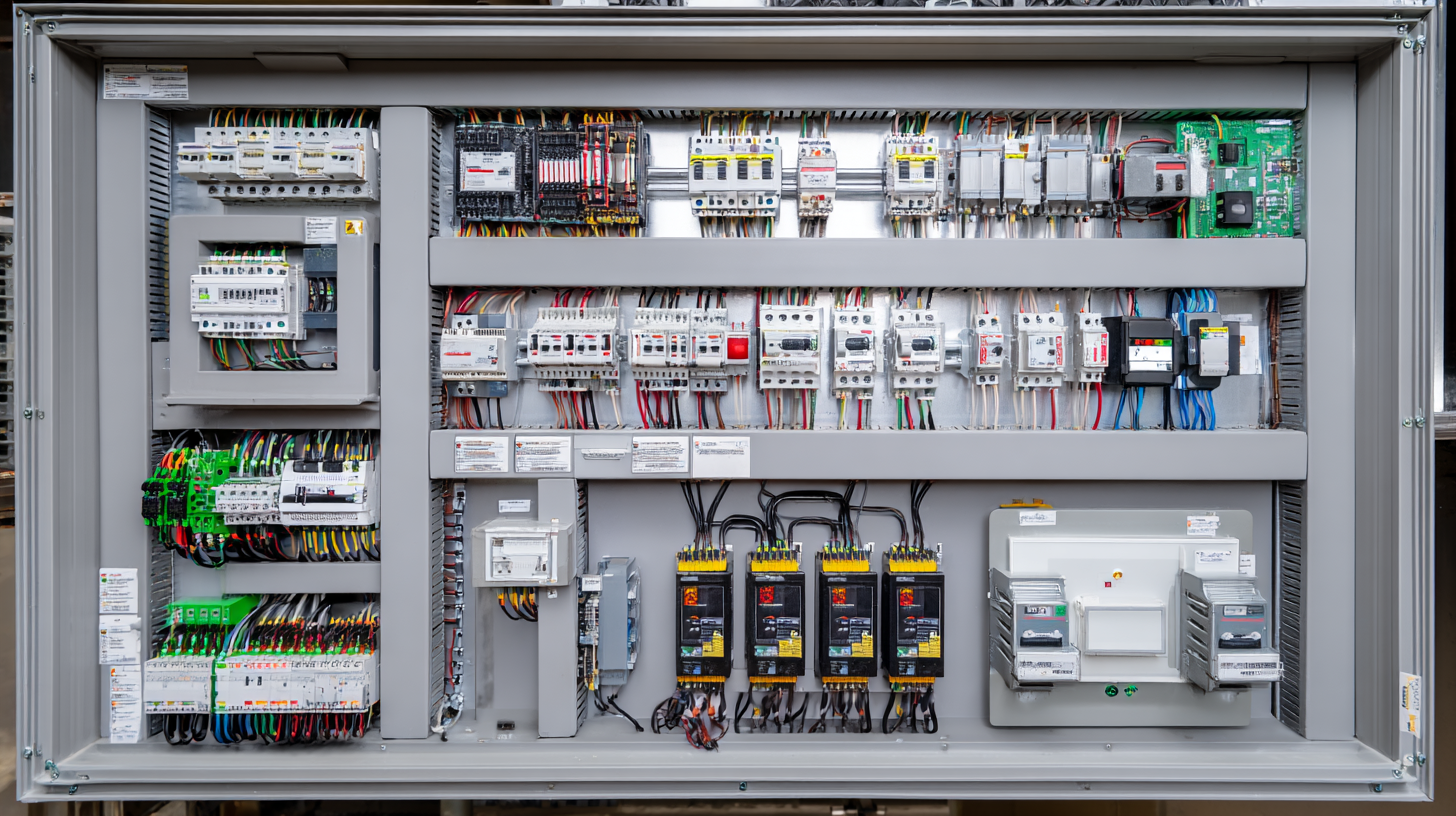

Key Components of Automation Control Panels in Industrial Applications

Automation control panels play a critical role in modern industrial systems, offering essential functionalities that drive efficiency and safety. Key components of these panels typically include circuit breakers, fuses, relays, and variable speed drives, which collectively ensure seamless operation of machinery. The market for motor control centers, a segment closely related to automation control panels, reflects significant growth potential, driven by advancements in automation technologies and the increasing prevalence of smart motors. Analysts suggest that the market is segmented by voltage—low and medium voltage—and by components that are crucial for effective power management and operational control.

The integration of innovative technologies within automation control panels has shifted the landscape of industrial applications. For instance, the incorporation of RFID readers has enabled enhanced tracking and monitoring capabilities, further optimizing manufacturing processes. As companies continue to embrace Industry 4.0 and smart manufacturing principles, the demand for sophisticated control panels that support these initiatives is expected to rise dramatically. This evolving market scenario, alongside potential initial public offerings (IPOs) from leading firms, signals a vibrant future for the automation sector, highlighting the importance of ongoing investment in smart industrial solutions.

Understanding the Role of Automation Control Panels in Modern Industrial Systems

| Component | Function | Importance | Typical Applications |

|---|---|---|---|

| Programmable Logic Controller (PLC) | Automates processes and controls machinery. | Critical for real-time control and automation. | Manufacturing, Robotics, Water Treatment |

| Human-Machine Interface (HMI) | Allows interaction between operators and machinery. | Essential for monitoring and user feedback. | Control Stations, Industrial Plants |

| Variable Frequency Drive (VFD) | Controls the speed of electric motors. | Improves energy efficiency and extends motor life. | Conveyor Systems, Pumps, Fans |

| Relay | A switch that opens and closes circuits. | Vital for safety and control logic. | Safety Systems, Control Panels |

| Power Supply Unit (PSU) | Provides power to control panel components. | Crucial for stable operation of devices. | All Automation Systems |

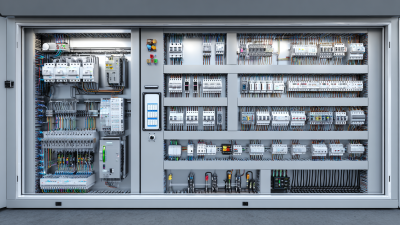

Integrating Automation Control Panels with IoT and Smart Technologies

The integration of automation control panels with IoT and smart technologies is transforming the landscape of modern industrial systems. Automation control panels serve as the nerve center for operational processes, enabling seamless communication between various machinery and control systems. By leveraging IoT connectivity, these panels can collect vast amounts of data in real time, allowing for more informed decision-making and enhanced operational efficiency. With sensors and devices linked through the internet, operators can monitor and control systems remotely, leading to a proactive rather than reactive approach to maintenance and troubleshooting.

Furthermore, the incorporation of smart technologies into automation control panels enhances their functionality and user experience. Smart algorithms can analyze trends and predict system failures before they occur, reducing downtime and operational costs. Additionally, intuitive user interfaces provide operators with comprehensive insights into system performance, facilitating quicker response times to anomalies. This synergy of automation control panels with IoT and smart technology not only improves productivity but also fosters an environment of innovation and adaptability in industrial operations. As industries embrace these advancements, the potential for optimization and intelligence in automation expands significantly.

Challenges and Considerations in Designing Automation Control Panels

The design of automation control panels in modern industrial systems presents several challenges that require careful consideration. One significant factor is ensuring the panels comply with industry standards and safety regulations. Designers must navigate various codes and certifications, such as the National Electrical Code (NEC) and International Electrotechnical Commission (IEC) standards, which dictate the operational safety and reliability of electrical installations. This compliance not only protects workers but also safeguards equipment, making it imperative for designers to stay updated on evolving regulations.

Another challenge is the technological integration of control systems. With the rise of the Internet of Things (IoT) and Industry 4.0, control panels must facilitate seamless connectivity between machinery and cloud-based systems. This requires designers to select the appropriate hardware and software, accounting for factors such as network security and data transmission efficiency. Additionally, ergonomic considerations play a critical role, as operators need intuitive interfaces for effective monitoring and control. Designers must strike a balance between complexity and usability, ensuring that the panel remains functional while being user-friendly, which is essential for maintaining operational productivity.

Understanding the Role of Automation Control Panels in Modern Industrial Systems

This bar chart illustrates the percentage of common challenges faced in designing automation control panels across various industrial sectors. Each sector presents unique considerations and obstacles that engineers must navigate.

Future Trends in Automation Control Panel Development and Usage

The future of automation control panels is poised to evolve significantly, driven by advancements in technology and an increasing demand for efficiency in industrial systems. One of the most prominent trends is the integration of the Internet of Things (IoT) into control panels. This connectivity enables real-time data monitoring and remote management, allowing operators to make informed decisions quickly.

As various devices and systems become connected, control panels will need to adapt to handle the influx of data and ensure seamless communication across platforms.

As various devices and systems become connected, control panels will need to adapt to handle the influx of data and ensure seamless communication across platforms.

Another emerging trend is the increased focus on user experience through intuitive interfaces and enhanced visualization tools. Modern control panels are shifting towards more user-friendly designs, with touchscreens and customizable dashboards that make it easier for operators to monitor and control processes. Furthermore, as industries move towards adopting artificial intelligence and machine learning, automation control panels will evolve to incorporate predictive analytics, enhancing operational efficiency and reducing downtime.

These advancements illustrate that the future of automation control panels will be characterized by a convergence of connectivity, user-centric design, and intelligent automation capabilities.

Related Posts

-

Exploring Innovative Control Panel Examples for Enhanced Industrial Efficiency

-

What is the Importance of PLC Programming in Modern Automation

-

How to Optimize Your Manufacturing Efficiency with VFD Control Panels

-

How to Optimize Your Electrical Control Panel Design for Maximum Efficiency and Safety

-

How to Create Efficient Electrical Control Panel Designs for Optimal Performance

-

Ultimate Guide to Choosing Control Cubicles for Maximum Efficiency