Top 10 Automation Control Panel Features You Need to Know for Efficiency

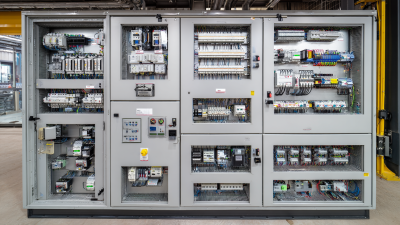

In today's fast-paced industrial landscape, efficiency is paramount, and the role of an automation control panel is more critical than ever. As businesses seek to streamline operations and enhance productivity, understanding the essential features of automation control panels becomes vital. These sophisticated systems are at the heart of automation, managing processes and ensuring that everything runs smoothly and effectively.

This article delves into the top 10 features you need to know about automation control panels to optimize efficiency in your operations. From user-friendly interfaces to advanced monitoring capabilities, each feature plays a significant role in facilitating seamless control and automation. By exploring these elements, organizations can harness the full potential of their automation control panels, leading to improved performance and reduced operational costs. Whether you are looking to upgrade existing systems or invest in new technology, being informed about these key features will empower decision-makers to choose the best solutions for their unique needs.

Key Features of Automation Control Panels for Improved Efficiency

Automation control panels are essential for enhancing efficiency in various industrial applications. These panels serve as the nerve center for controlling machinery and processes, and their key features significantly impact operational performance. One of the most crucial features is intuitive user interfaces that allow operators to quickly grasp system status and make informed decisions. Having a well-designed interface reduces training time and minimizes errors, enabling smoother workflows.

Another vital aspect of automation control panels is real-time monitoring capabilities. This feature allows operators to track performance metrics continuously and identify anomalies before they escalate into major issues. Additionally, implementing advanced data analytics tools within the control panel can provide actionable insights, helping teams optimize processes and resource allocation.

**Tips:**

- Ensure that your control panels are equipped with customizable dashboards that cater to your specific operational needs. This personalization enhances usability and aids in quicker decision-making.

- Regularly update the software and firmware of your automation control panels to leverage the latest features and improvements, ensuring your systems run smoothly and effectively.

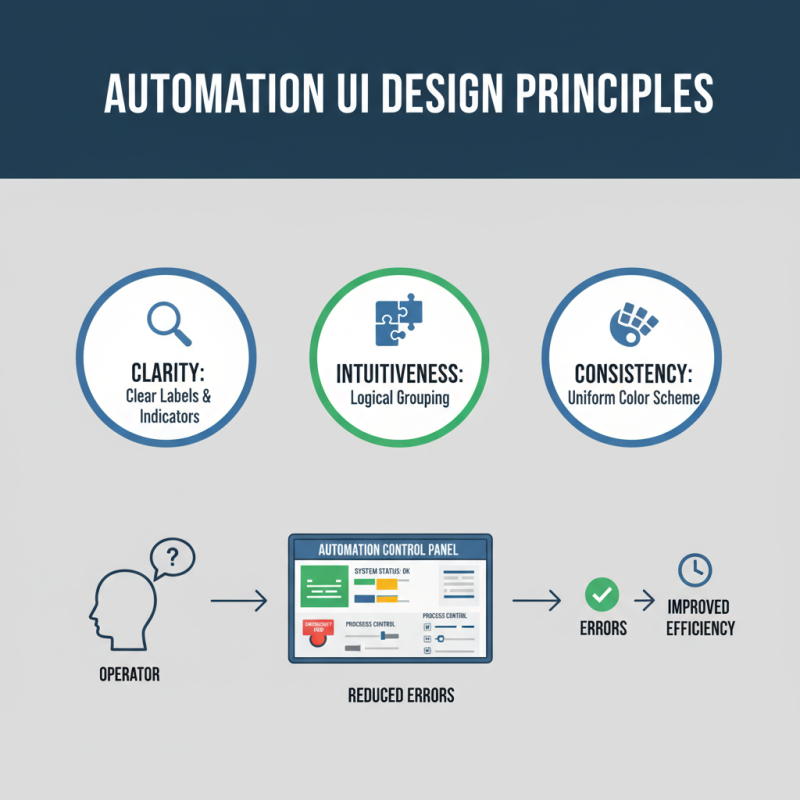

Understanding User Interface Design in Automation Control Panels

When designing user interfaces for automation control panels, clarity and intuitiveness are paramount. A well-structured interface allows operators to quickly understand and interact with the system, reducing the likelihood of errors and improving overall efficiency. Essential elements include clear labeling of controls and indicators, logical grouping of similar functions, and a consistent color scheme that conveys information effectively. By prioritizing these aspects of design, users can easily identify the status of the system and execute commands without unnecessary confusion.

Another critical element in user interface design for automation control panels is the integration of visual feedback. Operators should receive immediate, context-relevant information regarding their actions, which can be achieved through visual cues such as changing colors, alert icons, or animated graphics. This not only enhances the user experience but also allows for quicker responses to system changes. Furthermore, incorporating customizable settings enables users to tailor the interface according to their preferences and operational needs, thereby promoting a more efficient workflow.

The Role of Real-Time Monitoring in Automation Control Panels

Real-time monitoring is an essential feature of automation control panels, significantly enhancing operational efficiency across various industries. In fact, according to the International Society of Automation, organizations that implement real-time monitoring solutions can improve their overall process efficiency by up to 20%. This feature allows operators to track performance metrics, detect anomalies, and respond to system alerts immediately, thus minimizing downtime and ensuring smooth operations. With the rapid advancement of IoT technologies and data analytics, real-time data collection has become not only feasible but also essential for maintaining a competitive edge.

Furthermore, real-time monitoring facilitates predictive maintenance, which can lead to substantial cost savings. A study by the McKinsey Global Institute indicates that predictive maintenance can reduce maintenance costs by 10-30% and minimize unplanned downtime by up to 50%. By continuously analyzing data from sensors and equipment, control panels equipped with real-time monitoring can provide insights that empower companies to preemptively address potential issues before they escalate into major failures. This proactive approach not only optimizes machine performance but also extends the lifespan of critical components, ultimately contributing to greater efficiency and sustainability within industrial operations.

Top 10 Automation Control Panel Features

This chart illustrates the importance of various features in automation control panels that contribute to operational efficiency. The data represents a survey of industry professionals rating each feature from 1 to 10 based on its perceived value.

Importance of Data Logging and Reporting in Automation Control Systems

Data logging and reporting are essential components of automation control systems, playing a pivotal role in enhancing efficiency and performance. By systematically collecting data from various sensors and control devices, automation systems can monitor processes in real-time. This data provides invaluable insights into operations, allowing operators to identify trends, detect anomalies, and make informed decisions to optimize performance. The ability to log data over extended periods enables organizations to establish baselines, monitor fluctuations, and track improvements or regressions in their processes.

Moreover, robust reporting mechanisms are crucial for interpreting the vast amounts of data collected. Comprehensive reports can reveal critical performance metrics, helping teams understand the effectiveness of their automation solutions. These insights facilitate proactive maintenance, as patterns in the data may indicate potential failures before they occur. Additionally, well-structured reports aid in compliance with industry regulations by documenting operational standards and performance, ensuring that organizations remain accountable for their processes. Ultimately, effective data logging and reporting transform automation control systems from mere operational tools into powerful resources for strategic planning and continuous improvement.

Integrating Safety Features into Automation Control Panels for Reliability

Integrating safety features into automation control panels is essential for ensuring both operational reliability and worker protection. One of the primary considerations in this integration is the implementation of fail-safe mechanisms that can automatically shut down systems in the event of a malfunction. These mechanisms prevent accidents and reduce the risk of equipment damage, creating a safer environment for personnel. Additionally, utilizing robust emergency stop buttons that are easily accessible can enhance safety during unforeseen situations, allowing operators to halt processes quickly.

Another critical aspect of safety integration is the installation of advanced monitoring systems that provide real-time data on system performance and potential hazards. These systems can alert operators to abnormal conditions, enabling proactive measures to address issues before they escalate. Furthermore, incorporating redundant safety controls can significantly improve reliability; even if one system component fails, alternate systems can take over, maintaining safety and operational continuity. By prioritizing these safety features, businesses can foster a culture of safety while enhancing the overall efficiency and reliability of their automation control panels.

Related Posts

-

Revolutionizing Industries with Next Generation Automation Control Panels

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

What Are Electrical Control Solutions and How Do They Revolutionize Automation?

-

Exploring the Evolution of Control Panels: Industry Insights and Future Trends in Automation Technology

-

Understanding the Role of Electrical Control Solutions in Optimizing Energy Efficiency: Insights and Data