Top 10 Electrical Control Systems Revolutionizing Industrial Automation

In the rapidly advancing field of industrial automation, electrical control systems stand out as pivotal components driving efficiency and precision across various sectors. According to a report by MarketsandMarkets, the global industrial automation market is projected to reach $296.70 billion by 2025, with electrical control systems playing a critical role in this growth. As industries adopt smarter technologies to optimize processes, the demand for advanced control systems is surging, highlighting their importance in enhancing operational productivity and reducing costs.

John Smith, a leading expert in electrical engineering and automation technology, emphasizes the transformative impact of these systems, stating, “The evolution of electrical control systems is not just about automation; it’s about reinventing how industries operate.” His insights underline the fact that these systems have the potential to streamline workflows, improve safety standards, and enable predictive maintenance, which further positions companies to compete effectively in an increasingly automated marketplace. As we delve into the top ten electrical control systems revolutionizing industrial automation, it becomes evident that these innovations are setting new benchmarks for performance, reliability, and efficiency in manufacturing and beyond.

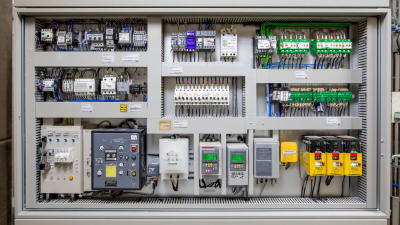

Identifying Key Features of Innovative Electrical Control Systems

Innovative electrical control systems play a pivotal role in revolutionizing industrial automation by enhancing efficiency, precision, and adaptability. One of the key features of these advanced systems is their integration with Internet of Things (IoT) technology, enabling real-time data exchange and remote monitoring. This connectivity allows for predictive maintenance and streamlined operations, significantly reducing downtime and operational costs. Furthermore, the incorporation of machine learning algorithms enables these systems to optimize processes autonomously, learning from historical data to improve performance continuously.

Another vital feature is modularity, which provides flexibility in scaling operations. Companies can easily adapt their control systems to accommodate new machinery or production lines without undergoing extensive overhauls. This flexibility is complemented by user-friendly interfaces that empower operators to interact with complex systems more effectively. By prioritizing safety and energy efficiency, contemporary electrical control systems not only enhance productivity but also promote sustainable practices, making them essential for modern industrial applications. These transformative elements collectively showcase how innovative electrical control systems are setting new benchmarks in industrial automation.

Integrating IoT Technology in Industrial Automation Control

The integration of IoT technology in industrial automation control systems is transforming how industries operate. IoT-enabled devices, utilizing cellular networks, allow for real-time remote monitoring and control of equipment through embedded SIM technology. This connectivity solution ensures seamless data transmission across vast areas and diverse environments, paving the way for innovations such as smart agriculture, where real-time data can optimize productivity and resource management.

As industries continue to adopt IoT technologies, the growth of the IoT chip market is significant. By 2024, the global IoT chip market is projected to be valued at $60.59 billion, with expectations to reach approximately $166.63 billion by 2032, demonstrating a robust compound annual growth rate (CAGR) of 13.5% during this forecast period. Such growth illustrates the increasing demand for intelligent systems that can enhance operational efficiency and drive automation, aligning with the industry's push toward more advanced and integrated control mechanisms.

Top 10 Electrical Control Systems Revolutionizing Industrial Automation

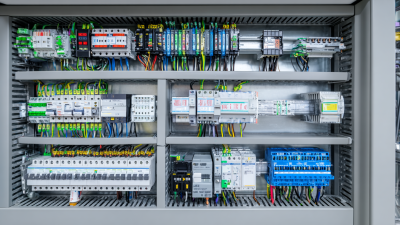

Enhancing Efficiency with Advanced PLC Systems

The advent of advanced Programmable Logic Controller (PLC) systems has significantly transformed industrial automation, paving the way for heightened efficiency and precision in manufacturing processes. According to a recent report by MarketsandMarkets, the global PLC market is projected to reach $28.2 billion by 2026, growing at a CAGR of 6.8% from 2021. This growth is driven by the increasing demand for automation in various sectors, including automotive, food and beverage, and pharmaceuticals, where PLC systems streamline operations and enhance productivity.

Modern PLCs boast advanced features such as real-time data processing and integration with the Internet of Things (IoT), which further optimizes operational efficiency. For instance, using IoT-enabled PLCs can yield energy savings of up to 25% by enabling predictive maintenance and real-time monitoring, as reported by a study published in the Journal of Automation and Control Engineering. By harnessing these capabilities, industries are not only able to reduce downtime and operational costs but also improve their response times to market changes, ultimately leading to a more competitive edge.

Top 10 Electrical Control Systems Revolutionizing Industrial Automation

| Control System | Key Features | Automation Benefits | Efficiency Improvement |

|---|---|---|---|

| Programmable Logic Controller (PLC) | Flexible programming, real-time monitoring | Increased production speed | Up to 30% increase |

| Distributed Control System (DCS) | Centralized control, extensive data acquisition | Improved process stability | Up to 25% reduction in downtime |

| Supervisory Control and Data Acquisition (SCADA) | Remote control capabilities, data logging | Enhanced monitoring capabilities | Improvement of 20% in resource management |

| Human-Machine Interface (HMI) | User-friendly visualization | Reduced human error | 20% reduction in operational errors |

| Industrial Internet of Things (IIoT) | Connectivity, real-time data analysis | Predictive maintenance | Up to 15% decrease in maintenance costs |

| Motion Control Systems | Precision control, feedback systems | Enhanced product quality | Increase of 10% in quality compliance |

| Intelligent Power Distribution Systems | Integration with renewable energy sources | Energy efficiency | Reduction of energy costs by 15% |

| Vision Systems | Image processing, quality inspection | Increases inspection speed | 30% boost in inspection throughput |

| Safety Instrumented Systems (SIS) | Risk mitigation, compliance | Improved workplace safety | Reduction in accidents by 30% |

| Cloud-Based Control Systems | Remote access, data storage | Scalability | Increased flexibility leading to 25% lower IT costs |

Utilizing AI for Predictive Maintenance in Control Systems

The utilization of AI for predictive maintenance in electrical control systems is transforming industrial automation, marked by a significant uptick in market value. The global manufacturing market is projected to see its $5.65 billion AI value reach in 2024, with a remarkable compound annual growth rate (CAGR) of 45.11% expected between 2025 and 2032. This growth is propelled by advancements such as digital twin technology, which enhances simulation design and high-resolution modeling. This allows for more precise manufacturing processes, leading to innovations in product design and operational efficiency.

Moreover, sectors such as digital railways are experiencing substantial growth driven by urbanization and increased reliance on public transit. By leveraging predictive maintenance, industries can minimize downtime, optimize performance, and enhance safety. The digital railway market alone is expected to grow at a CAGR of around 9.4% from 2024 to 2032. As industries invest more in intelligent control systems and embrace these emerging technologies, the impact on operational excellence and cost savings will be profound, signifying a new era in industrial automation.

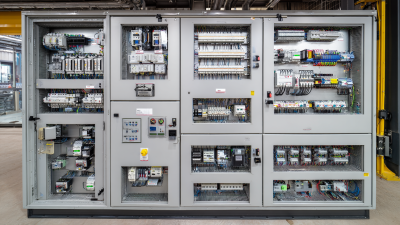

Exploring Modular Control Solutions for Flexible Manufacturing

In the age of Industry 4.0, modular control solutions are increasingly vital in enhancing the flexibility and efficiency of manufacturing processes. These systems allow for adaptable configurations, enabling businesses to swiftly respond to changing production demands. By integrating scalable components, manufacturers can easily reconfigure their setups without extensive downtime or costs. This adaptability not only streamlines operations but also supports the integration of innovative technologies, ultimately driving productivity and reducing resource wastage.

Tip: When implementing modular control systems, focus on training your workforce on the flexibility features. A well-informed team can leverage these systems to maximize efficiency and minimize errors, leading to a more agile manufacturing environment.

The shift towards modular systems also supports the customization of products, allowing for specialized manufacturing without sacrificing speed. Companies can create tailored solutions, accommodating specific customer needs that conventional systems may not easily address. This level of customization is integral in developing competitive advantages in today's dynamic market landscape.

Tip: Regularly assess your modular systems for updates and enhancements. Staying current with technological advancements ensures your operations remain competitive and can adapt more efficiently to new challenges.

Related Posts

-

Top 5 Essential Control Systems for Optimizing Industrial Automation

-

How to Optimize Your PLC Panel for Maximum Efficiency and Performance

-

What is the Importance of PLC Programming in Modern Automation

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

What Are Electrical Control Solutions and How Do They Revolutionize Automation?

-

Exploring the Evolution of Control Panels: Industry Insights and Future Trends in Automation Technology