Top 10 PLC Controller Programming Tips You Should Know?

In the world of automation, PLC controller programming stands as a critical skill. Many engineers grapple with its complexities. Learning effective techniques can significantly enhance your programming skills.

Good programming practices can streamline processes. For instance, using clear naming conventions improves code readability. Efficient coding reduces errors and saves time during troubleshooting. However, beginners often make common mistakes, like neglecting documentation. This can lead to confusion later.

Moreover, understanding logic fundamentals is a must. Basic principles underpin advanced functions. Yet, many fail to grasp these essentials at first. Emphasizing simulation, testing, and revision is key. A great programmer constantly seeks improvement and adapts to challenges in PLC controller programming.

Understanding PLC Controllers and Their Importance in Automation

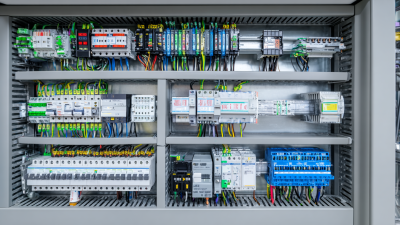

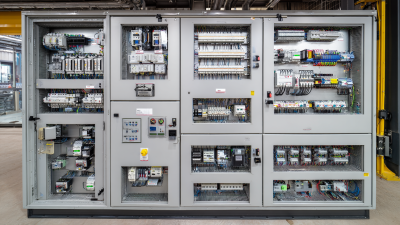

Programmable Logic Controllers (PLCs) play a vital role in modern automation. They are essential for controlling machinery and processes in various industries. PLCs ensure that operations run smoothly, efficiently, and safely. Automation reduces human error. It allows for precise control over complex systems. This precision leads to increased productivity and reduced downtime.

Understanding PLCs requires a grasp of their functionality. They process inputs from sensors and make decisions based on pre-set logic. Outputs trigger machinery or systems to respond accordingly. This real-time reaction is critical in environments like manufacturing and assembly lines. However, programming PLCs can be challenging. Mistakes in code can halt production. Testing and debugging are crucial steps in the process.

The importance of PLCs in automation cannot be overstated. They bring a level of reliability and control that is hard to match. Yet, as with any technology, there are learning curves. Programmers must be patient and persistent. Projects may not always go as planned. Reflecting on past experiences can foster better programming practices. Embrace the journey of learning and grow with each challenge faced.

Top 10 PLC Controller Programming Tips You Should Know

| Tip Number | Programming Tip | Description | Importance |

|---|---|---|---|

| 1 | Understand the Basics | Familiarize yourself with PLC fundamentals to build a strong foundation. | High |

| 2 | Use Clear Naming Conventions | Name your variables and functions clearly for better readability. | Medium |

| 3 | Comment Your Code | Add comments to your code for future reference and team collaboration. | High |

| 4 | Keep It Simple | Avoid complex solutions when a simpler one will suffice. | High |

| 5 | Test Incrementally | Test your code in small increments to isolate errors early. | High |

| 6 | Utilize Simulation Tools | Use simulation software to visualize PLC operation before deployment. | Medium |

| 7 | Document Your Projects | Maintain thorough documentation for future reference. | High |

| 8 | Learn from Others | Engage with the community to learn best practices and solutions. | Medium |

| 9 | Regularly Update Skills | Keep up to date with new technologies and programming languages. | High |

| 10 | Backup Your Code | Always create backups to prevent loss of work. | Critical |

Basic Programming Concepts for Effective PLC Coding

When programming PLCs, understanding basic concepts is crucial. Start with clear logic structures.

Utilize simple diagrams to visualize processes. Break down complex tasks into smaller steps. This method helps avoid confusion and enhances program readability.

A well-organized code is easier to troubleshoot.

Variables play an important role in coding. Clearly define each variable’s purpose. Use meaningful names that reflect their function.

Keep your naming conventions consistent. This practice makes it easier for others to read your code. It also helps you remember what each part does.

Indents and comments can enhance clarity. However, too many comments may clutter your code. Aim for balance. Write enough to explain complex sections,

but don't overdo it. In some cases, it's better to ask a colleague for a fresh perspective.

Collaborative coding can bring new ideas and prevent potential oversights.

Remember, learning from mistakes is vital in programming.

Common Mistakes to Avoid When Programming PLCs

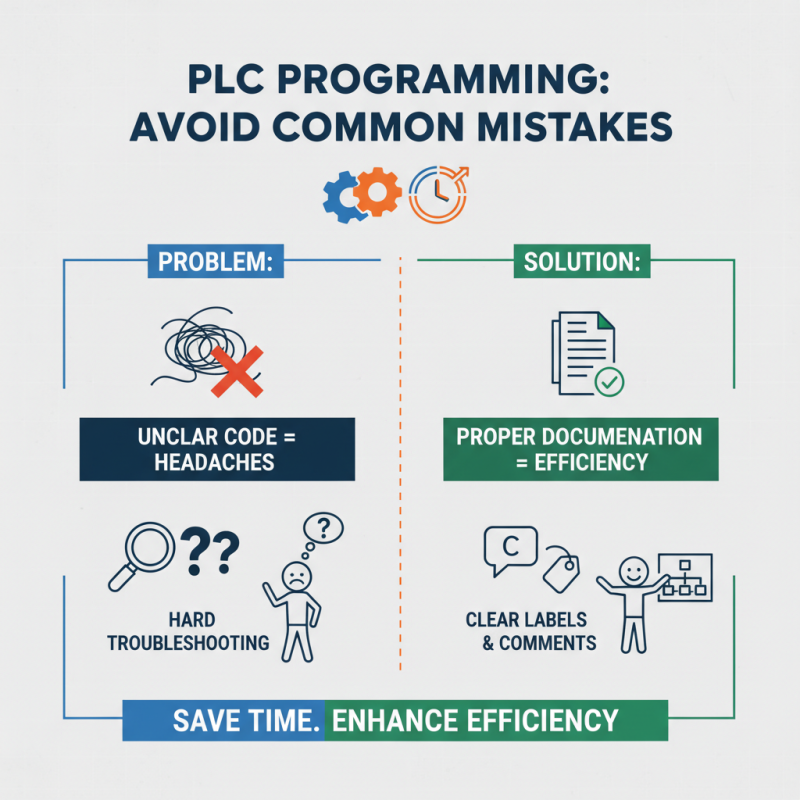

When programming PLCs, avoiding common mistakes can save time and enhance efficiency. One frequent error is neglecting proper documentation. Clear labels and detailed comments are essential. Without them, future troubleshooting becomes harder. Everyone knows how frustrating it is to decipher unclear code.

Another common pitfall is underestimating the importance of simulation. Skipping the testing phase can lead to unexpected failures. Running simulations before deploying can catch issues early on. Sometimes, we rush through this step, thinking we’re saving time. Yet, it often results in bigger problems later.

Not considering the hardware limits can also derail a project. Each PLC has specific capabilities and restrictions. Failing to understand these can lead to program errors or system overloads. Ignoring documentation can lead to conflicts that disrupt operations. Reflecting on past mistakes can improve future projects.

Best Practices for Debugging and Testing PLC Programs

Debugging PLC programs can be challenging. It's common to feel frustrated when code doesn't work as intended. Start by simplifying the problem. Break down the logic into smaller sections. Test each part individually. This method can reveal hidden issues.

Visual tools are essential in this process. Use diagrams to illustrate the control flow. They can help identify logical errors. Consider adding comments in your code. Notes clarify your thought process. They aid others who view your code later. Misleading comments can lead to confusion.

Take time to ensure they are accurate.

Running simulations can expose flaws before implementation. If available, create a digital twin of your system. It mimics real-world behavior. Experimenting with digital twins helps build confidence in the code.

However, not all errors show up in simulations. Real-life testing may present unexpected problems. Be prepared for adjustments. Reflecting on each issue can improve future programming.

Tips for Enhancing PLC Program Readability and Maintenance

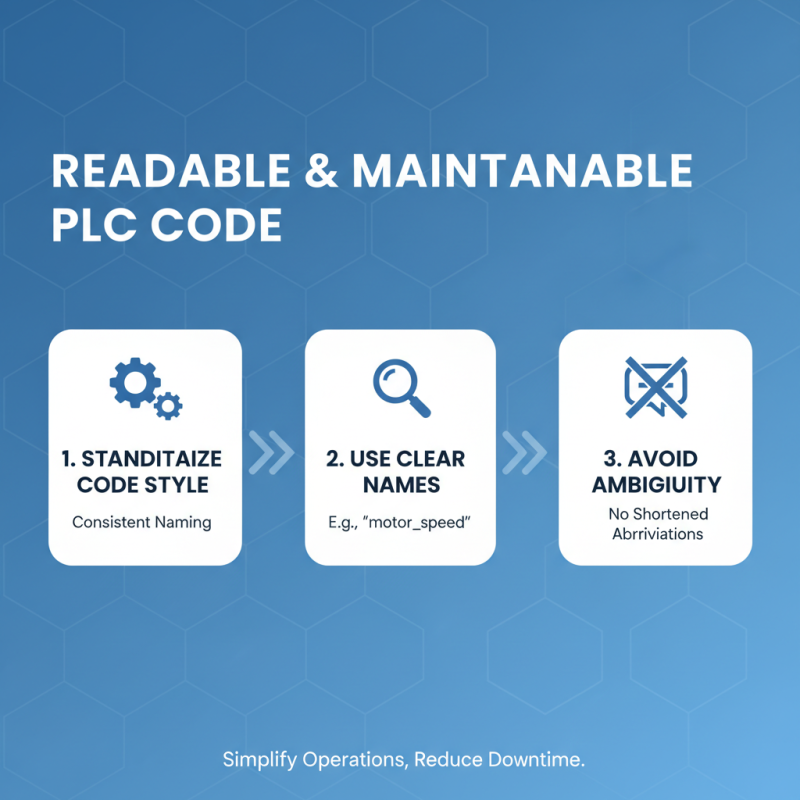

Creating readable and maintainable PLC programs is essential for successful operations. Start by standardizing your code style. Use consistent naming conventions for variables and functions. This makes it easier to understand your code at a glance. For example, using clear and meaningful names like "motor_speed" helps others understand your logic. Avoid ambiguous abbreviations. They often lead to confusion later.

Commenting your code is key to maintaining clarity. While it may seem tedious, it pays off in the long run. A simple note explaining the purpose of a function can save hours of troubleshooting. Keep comments concise. This avoids clutter but provides necessary context. Additionally, consider using whitespace effectively. It can greatly enhance readability. A cluttered program can cause frustration.

Finally, regularly review your code. A fresh pair of eyes might spot issues you overlooked. This is where reflection comes in. Ask yourself if this code meets the readability standard you strive for. If not, don't hesitate to revise it. It’s a continuous improvement process. Remember, clarity reduces errors and makes future updates simpler.

Related Posts

-

How to Master PLC Controller Programming for Industrial Automation

-

Essential Guide to Mastering PLC Controller Programming Techniques

-

The Future of Control Solutions: Transforming Industry Standards with Smart Technology Integration

-

Exploring the Evolution of Control Panels: Industry Insights and Future Trends in Automation Technology

-

The Rise of Control Cubicles in Modern Workspaces Enhancing Productivity and Employee Satisfaction

-

Enhancing Industrial Efficiency: The Future of PLC Control Systems in Smart Manufacturing