An efficient control panel layout is essential for the long-term performance and safety of industrial electrical systems. A well-designed layout helps reduce component wear, lowers energy use, and simplifies maintenance, all while keeping panel size and costs under control.

At Keltour, we specialize in building custom control panels for a variety of industries. Each one is designed and assembled with three core principles in mind: thermal management, space optimization, and serviceability.

These principles ensure that every control panel we manufacture meets or exceeds customer requirements and is easy to manage over its entire service life.

This article will outline the best practices in control panel layout that support those goals and highlight the Keltour approach to panel design.

Understanding Control Panel Layout

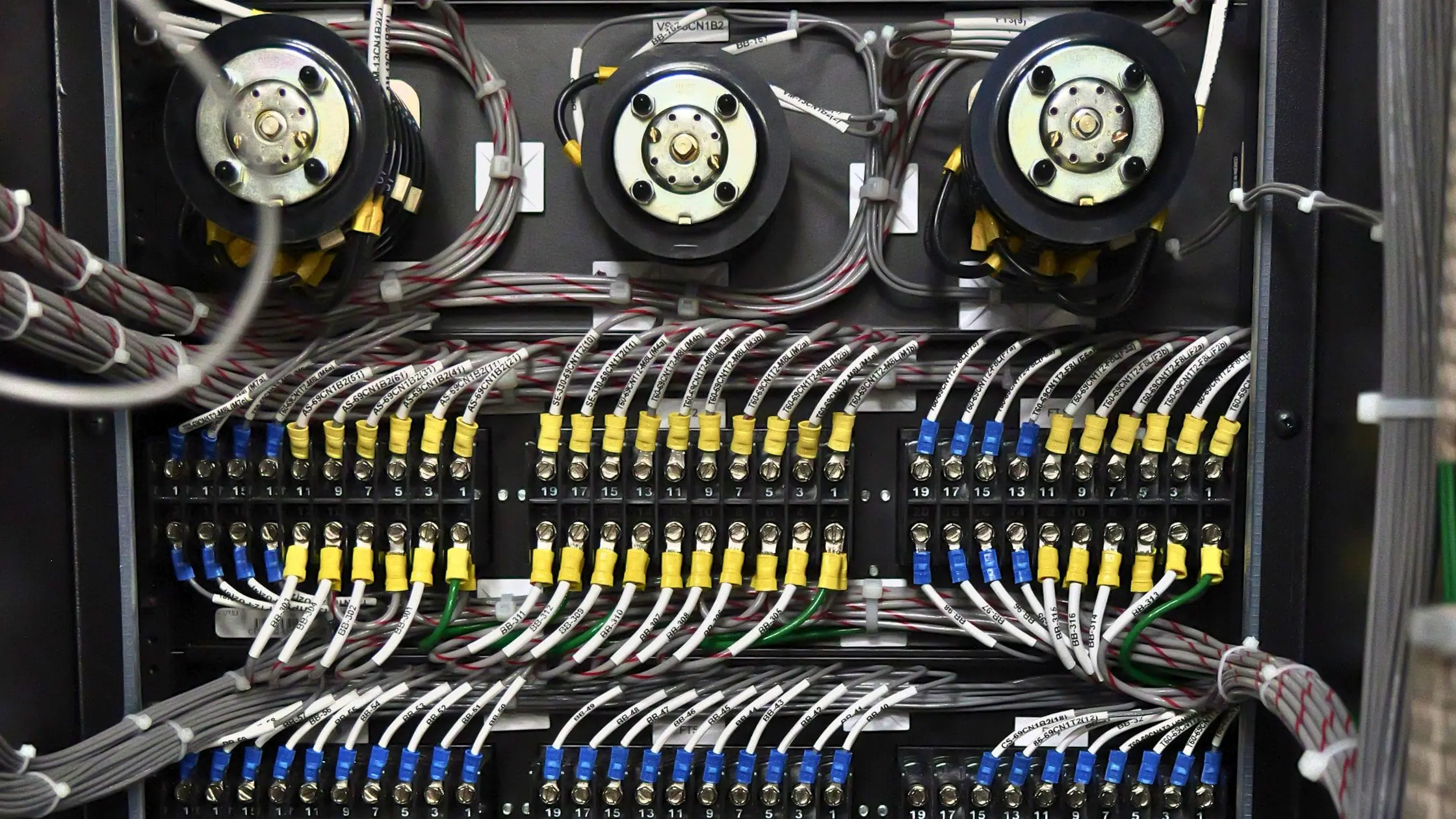

A control panel layout refers to the arrangement of electrical components inside an enclosure. This includes circuit breakers, terminal blocks, power supplies, PLCs, VFDs, relays, contactors, and more.

The layout determines not only how efficiently a panel functions, but also how safe and easy it is to operate and maintain.

Proper layout design takes into account component heat generation, wiring paths, space requirements, and future service needs. A disorganized or overcrowded panel increases the risk of heat buildup, electrical faults, and difficult maintenance, all of which can lead to downtime or failure.

1. Thermal Management in Control Panel Layout

Heat is a natural byproduct of electrical operation, especially in industrial environments where power-hungry equipment is used. If not properly managed, heat can degrade components, shorten their lifespan, and impact performance. For that reason, thermal management is a critical element of any control panel layout.

We address thermal considerations from the beginning of the design phase. Our engineers review the placement of heat-generating devices such as VFDs, power supplies, and contactors to ensure they are spaced appropriately and not obstructing airflow.

Where possible, these components are installed in zones that allow for natural convection or fan-assisted ventilation.

We also consider the enclosure type and its thermal properties. Panels that are exposed to high ambient temperatures or outdoor environments may require active cooling through air conditioners or heat exchangers. In some cases, we recommend NEMA 12, 4X, or enclosures that include built-in ventilation and condensation protection.

Thermal barriers and ventilation channels can also be integrated into the design to help separate hot and cool zones. Combined with a logical wiring scheme and appropriately sized wire ducts, these strategies promote better airflow and reduce the risk of overheating.

2. Space Optimization: Making the Most of Every Inch

Space optimization in control panel layout is not just about fitting components into an enclosure. It’s about doing so in a way that supports safety, accessibility, and cost-effectiveness. At Keltour, we understand that a compact, well-organized layout can significantly improve installation, testing, and ongoing maintenance.

To achieve this, we use modular components and DIN rail-mounted devices that streamline layout and wiring. This approach allows for high-density installations without compromising safety or accessibility. When laying out components, we plan for clearances required by standards like UL 508A and CSA guidelines to maintain proper wire bending radius and safe touch zones.

We also take advantage of multi-functional devices, such as combined motor starters or integrated PLC-VFD-HMI assemblies. These devices can reduce the total number of components in a panel, freeing up space and simplifying the design.

Wire routing is another area where space optimization is critical. Our layouts are designed to minimize wire crossings and congestion by using vertical and horizontal wire duct paths. Labelling is clear and consistent, allowing technicians to trace and troubleshoot connections quickly.

By optimizing space early in the design process, we can often reduce the overall panel size, leading to savings on materials, shipping, and installation.

3. Serviceability: Design with Maintenance in Mind

A control panel may be built to last, but even the best equipment requires periodic inspection and maintenance. That is why serviceability is a key part of how we approach control panel layout.

Serviceable control panels are those that make it easy for technicians to access:

- Key components

- Identify wiring

- Perform routine checks or part replacements without disrupting operations

At Keltour, we build this thinking into every layout.

Terminal blocks, circuit breakers, and fuses are placed in easily accessible rows. All wiring is labelled according to customer documentation and industry best practices.

Where appropriate, we use swing-out racks, hinged doors, and removable panels to provide clear access to internal sections.

Each panel comes with a detailed drawing package, often prepared using AutoCAD Electrical. These drawings match the physical layout of the panel, making it simple for electricians and maintenance personnel to navigate and understand the system.

In addition to this, we design with the future in mind.

Room for expansion is included where possible, allowing additional relays, I/O, or control devices to be added later without requiring a complete redesign.

Diagnostic ports and maintenance terminals can be integrated for easier troubleshooting and monitoring.

These design choices reduce downtime and make servicing safer and more efficient.

Built-In Quality from Design to Delivery

At Keltour, our design and manufacturing teams work together to ensure every control panel meets the highest standards of quality, functionality, and ease of use. All layouts are subject to a quality control process that includes point-to-point wiring checks, visual inspections, and functional testing.

Additionally, we follow strict internal standards that align with customer specifications and certification requirements. Our panels are built to comply with CSA, UL, CE, and other applicable standards, ensuring reliable performance in every application.

With over 50 years of experience and thousands of panels shipped around the world, Keltour is trusted by clients across industries, including water treatment, manufacturing, food and beverage, utilities, and more.

Optimizing Your Control Panel Layout Starts with Smart Design

In summary, a smart control panel layout is the foundation of a high-performance electrical system. When designed with thermal management, space optimization, and serviceability in mind, control panels last longer, operate more efficiently, and are easier to maintain.

Keltour Controls Inc. is dedicated to delivering cutting-edge control panel solutions to industrial manufacturers and businesses. Our range of offerings includes custom control panels and more.

Ask us about the types of custom control panels we offer, including but not limited to:

- Local control panels

- Protection & Control Panels

- Vehicle-mounted control panels

- Operator console panels

- Lighting control panels

- Test panels

- Conveyor panels

- Food & Beverage panels

- SCADA control panels

- PLC Control Panels

- Distribution Panels

- VFD panels

We strictly comply with safety and operational regulatory standards and have a proven track record of success that you and your company can depend on.

Contact Keltour to learn more about our custom control panel solutions, including full control system support.

Follow us on LinkedIn for the latest company news.